Functions and Features

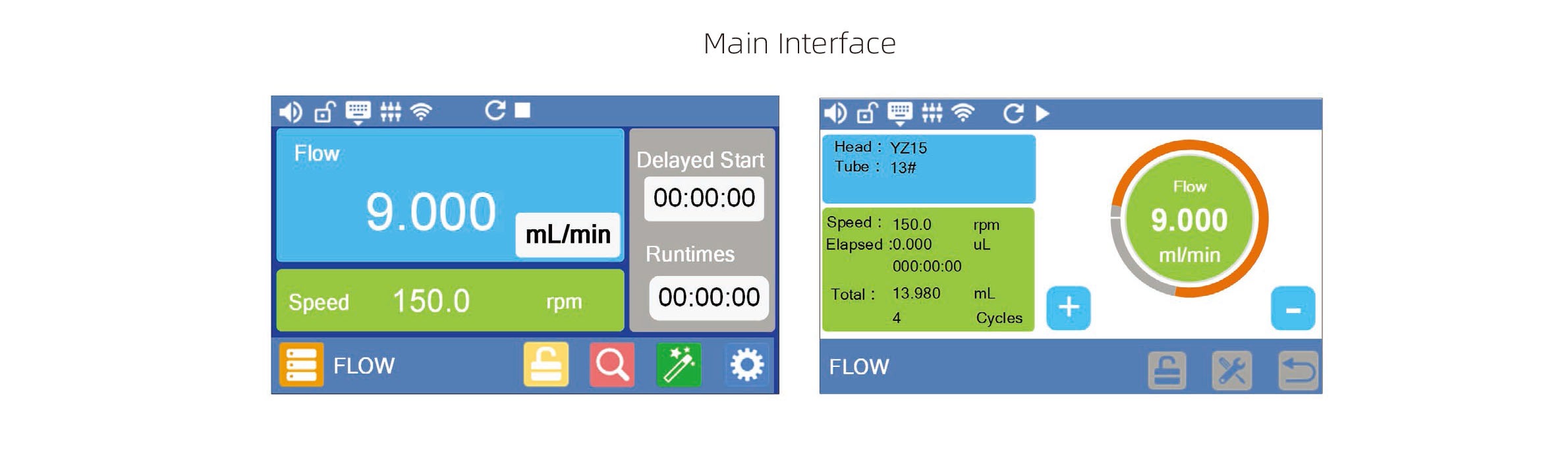

• 4.3 inch color LCD display, visual.

• Touch screen cooperates with keypads operation, bring good user experience.

• LF-Touch-OS software system, efficient and stable, has a good human-computer interaction mode. convenient product customization and upgrading.

• With the standard function such as start/stop, reversible direction,full speed, back suction, state memory, Can directly input flow or speed parameters .

• With the flow and time working mode.

• Precise flow control and display, micro-step algorithm to ensure the dispensing accuracy of different settings.

• Wizard-type flow calibration function, simple and easy to use.

• Delay start and delay stop function.

• Unique back suction function to effectively prevent liquid dripping.

• Reserved five-group dispensing parameters for time dispensing.

• Intelligent temperature control function, automatically adjust heat dissipation according to the environment, so that the equipment is always in the best state.

• WiFi control function(optional), remote operation can be realized through the Lead Fluid APP software, and has monitoring functions such as shutdown alarm and reminding to replace the pump tube.

• External analog speed regulation, external control signal control start-stop, reversible direction, dispensing, external control signal , physical isolation.

• RS485 communication, the MODBUS protocol, supporting up to 80 programming instructions, convenient connect with various control devices.

• Open multiple control parameters for OEM customized applications.

• The circuit board is sprayed with three anti paint processes to achieve dust and moisture-proof effect.

• Super Anti-interference characteristics, wide voltage design, suitable for complex power supply environment.

Specifications

- Flow range: 0.005~1750mL/min

- Speed range: 0.1~350 rpm

- Speed resolution: 0.1rpm

- Speed accuracy: <±0.2%

- Delayed startup time: 0.1~999.9 S/Min/H

- Delay stop time: 0.1~999.9 S/Min/H

- Dispensing time: 0.1~99.99 S/Min/H, time unit adjustable

- Dispensing number: 1~999, 0 Infinite cycle

- Dispensing interval: 0.1~999 S/Min/H

- External control signal input: (1) Start/Stop: passive contact, external control input level (5~24V) (2) Forward/Reverse: passive contact, external control input level (5~24V) (3) Speed Regulation: analog 0~5V, 0~10V, 4~20mA can be set.

- External control signal output: (1) Start/Stop: Level Signal (following input voltage) (2) Forward/Reverse: Level Signal (following input voltage) (3) Speed Status: Analogue 0~5V

- Communication interface: RS485 communication interface, Modbus protocol is available

- Power supply: AC100~240V,50Hz/60Hz

- Power consumption: <50W

- Working environment: Temperature 0 ~ 40℃, relative humidity<80%

- IP grade: IP31

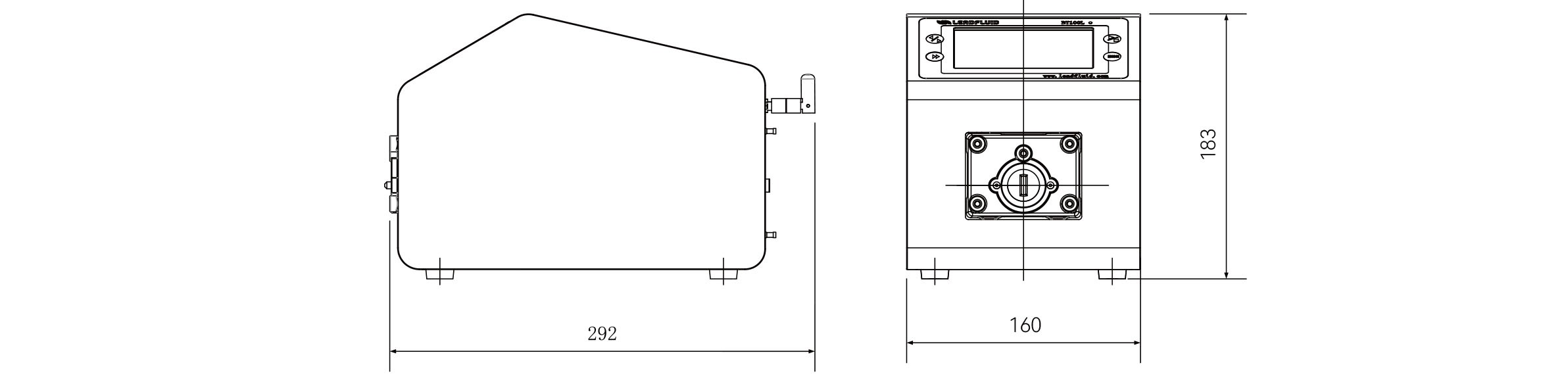

- Dimension(L×W×H): 292X160X183mm

- Weight: 4.5 kg

BT300L Suitable Pump Heads and Tubing, Flow Parameters

| Drive type | Pump head | Ch | Tubing size (mm) | Flow rateper channel (mL/min) |

| BT300L | YZ15/YZ15T | 1,2 | 13#14#19#16#25#17#18# | 0.005~1495 |

| YT25 | 1 | 114#116#15#24#35#36# | 0.024~1750 | |

| DT15-24 | 2 | 19#16#25#17# | 0.67~1307 | |

| DT15-44 | 4 | 19#16#25# | 0.67~770 |

Above flow parameters are obtained by using silicone tube to transfer pure water under normal temperature and pressure, in actually it is effected by specific factors such as pressure, medium, etc. Above for reference only.

Dimension (mm)

Statement:The final explanation right of above information belongs to Lead Fluid.

Reviews

There are no reviews yet.