MAIN PRODUCT CATEGORIES

Your one-stop solution, including peristaltic pumps, syringe pumps, gear pumps ODM customization,and product accessories!

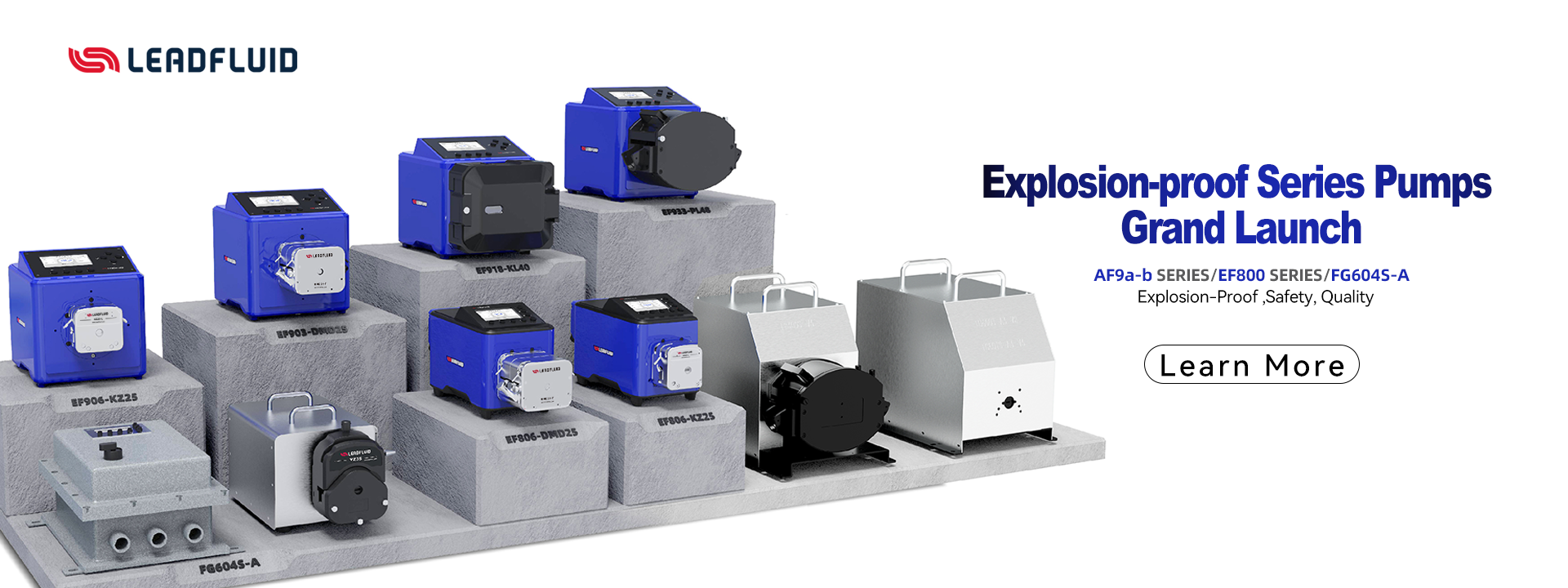

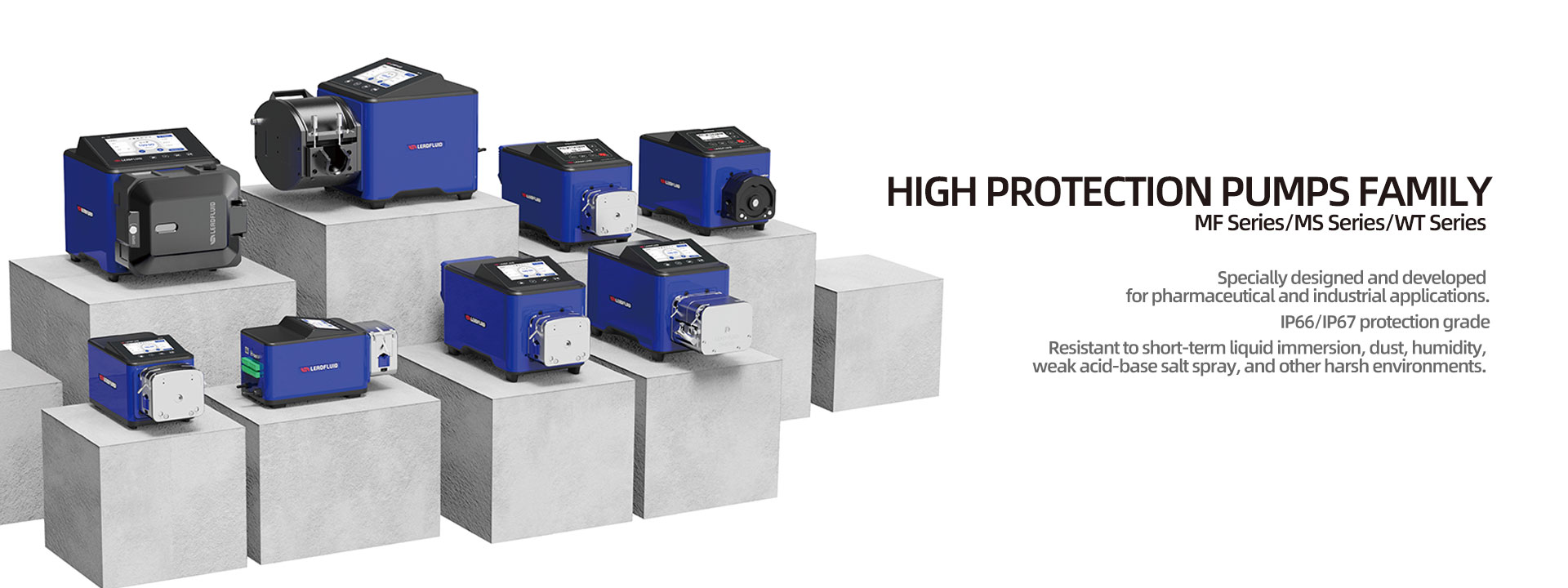

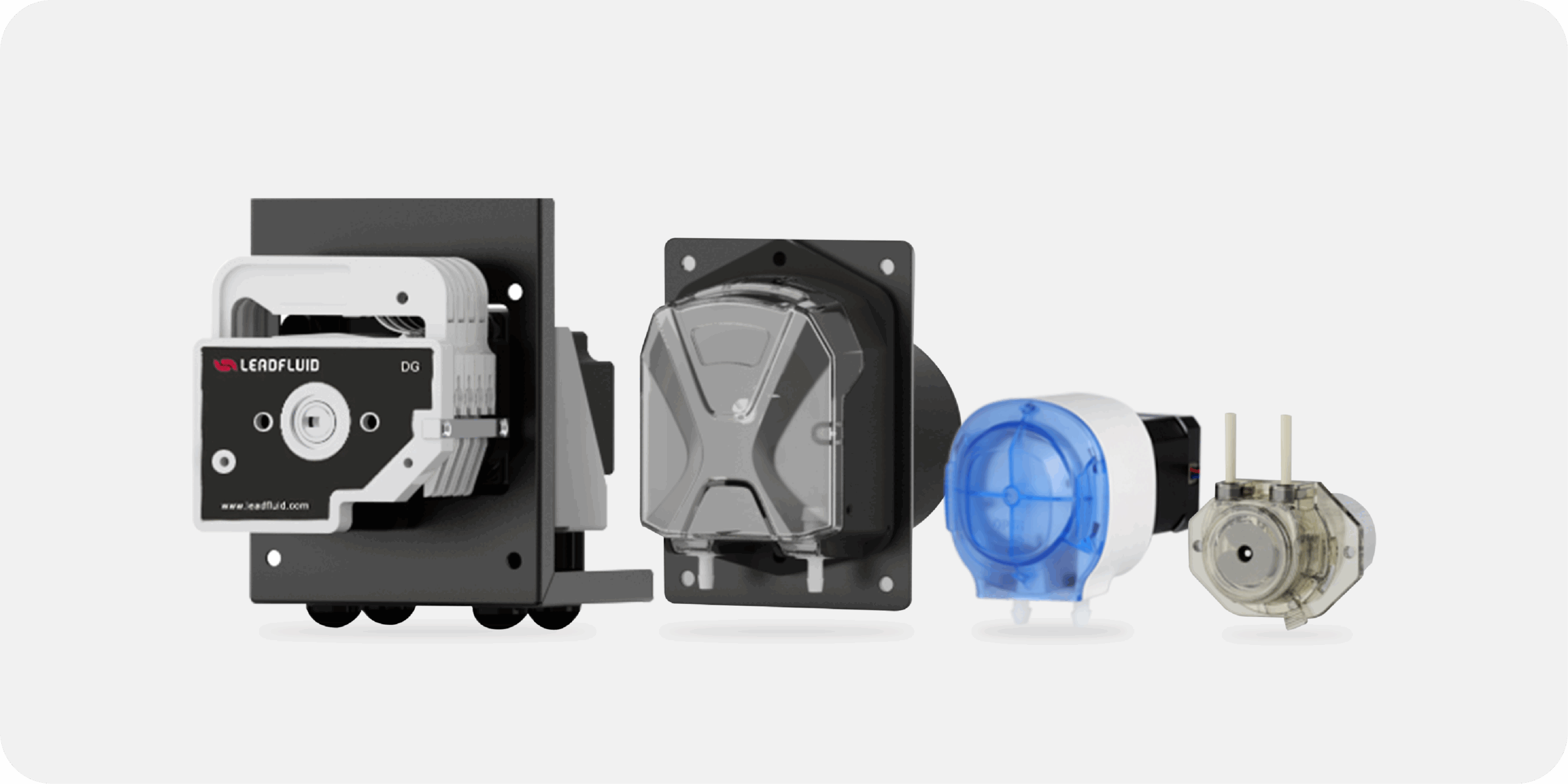

Peristaltic Pump

Contaminant-free flow by tube compression

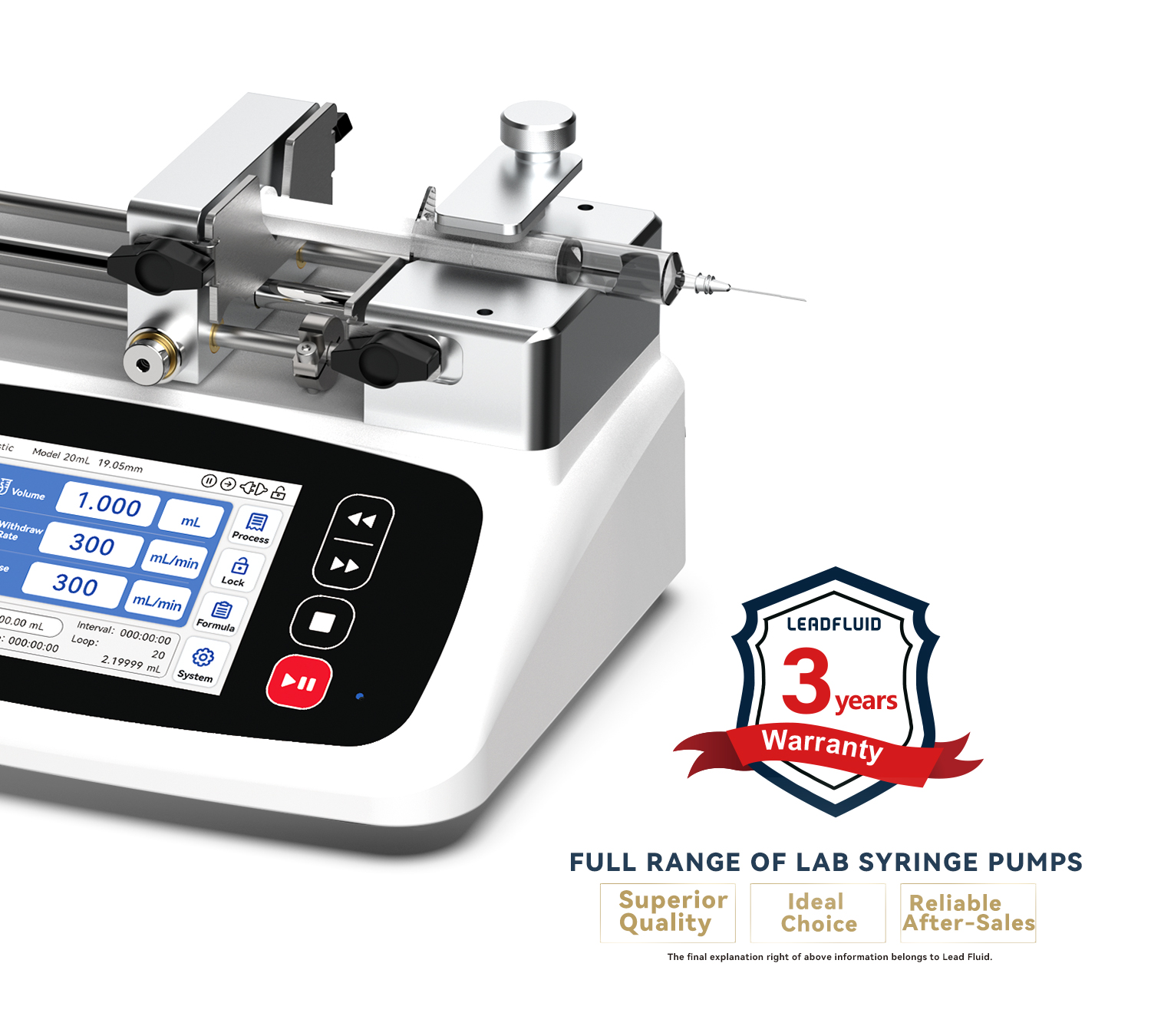

Syringe Pump

Delivers ultra-precisemicro-volume injection

Gear Pump

High-viscosity, high-pressure fluid transfer

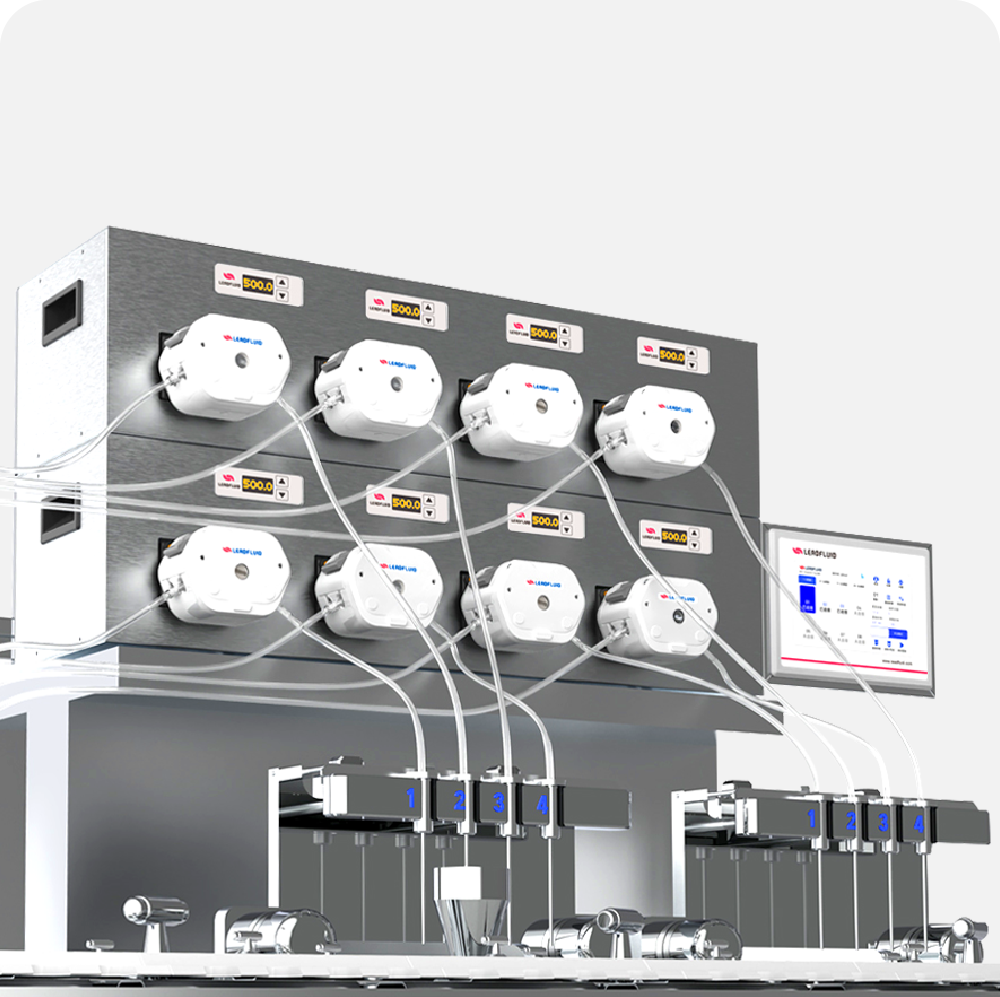

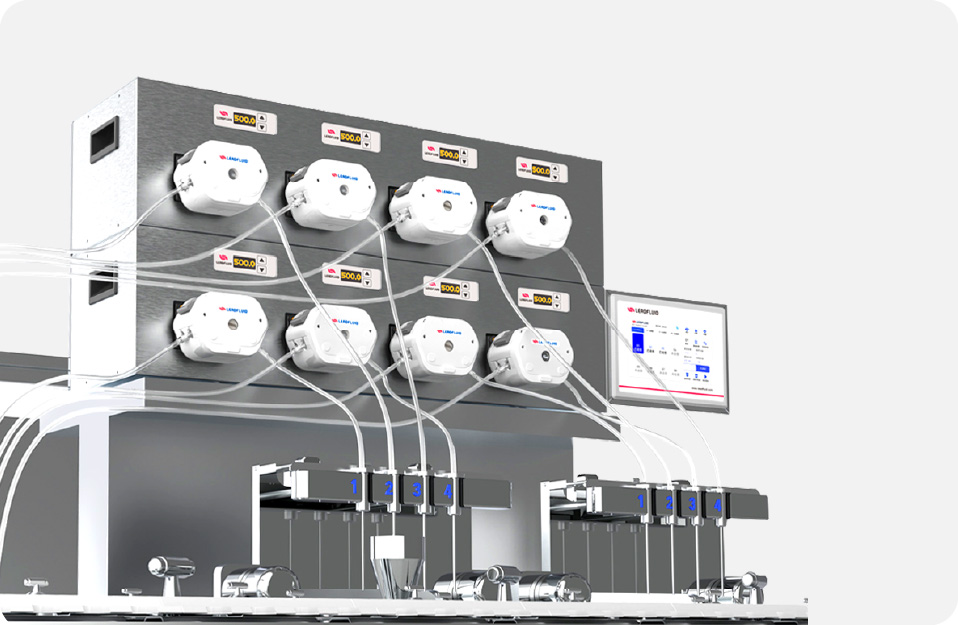

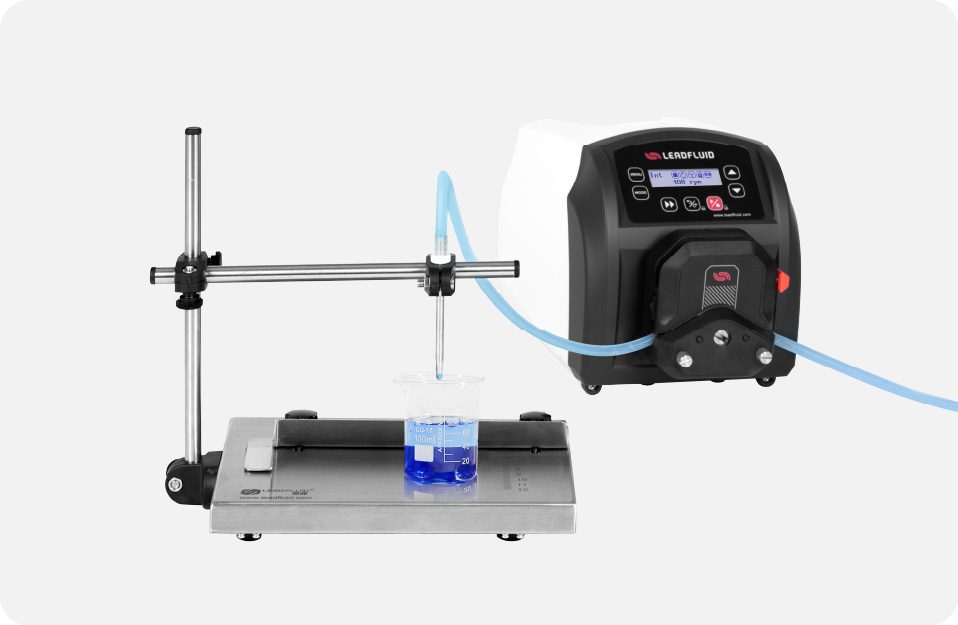

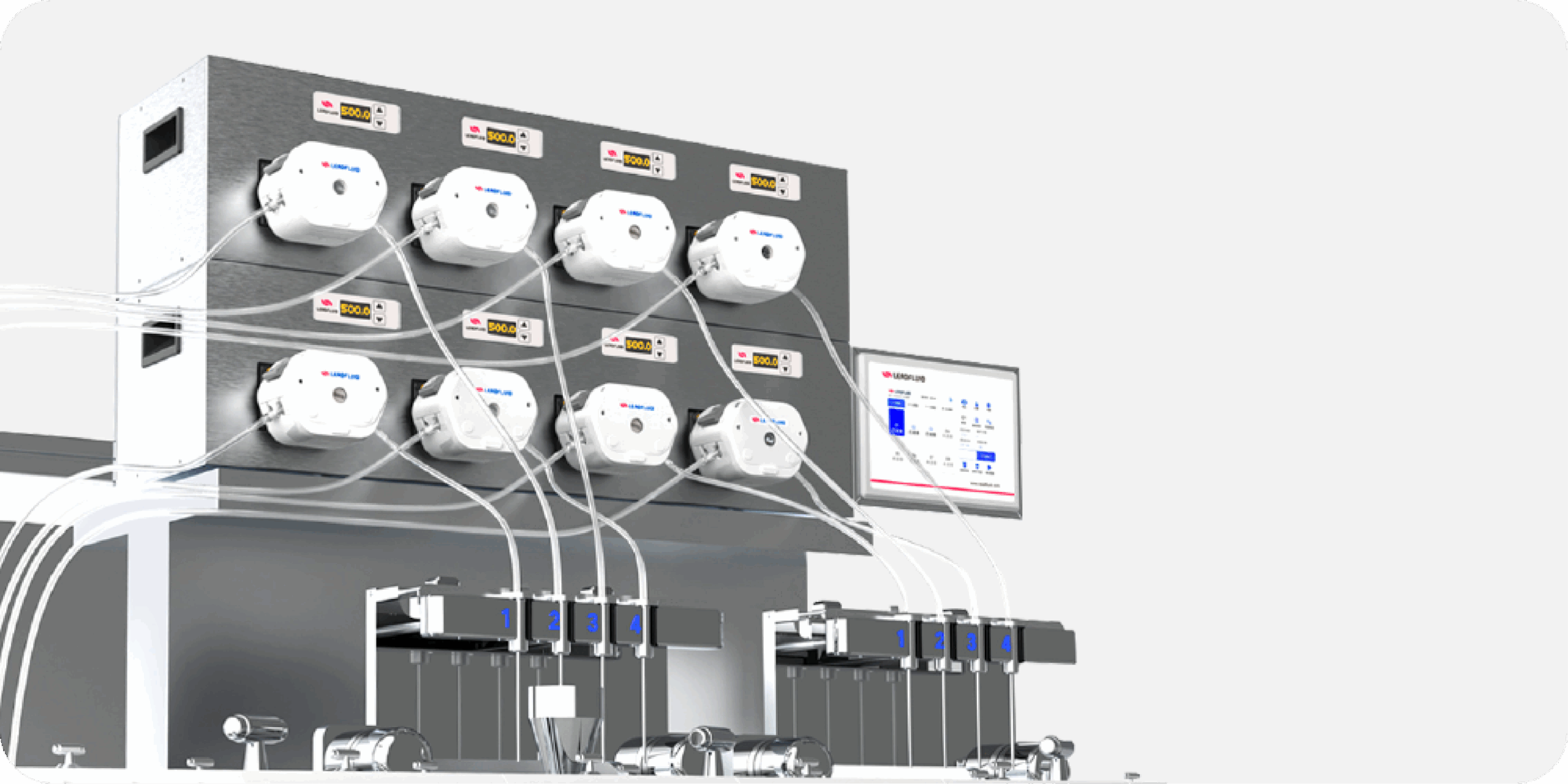

Filling System

Multi-channel high-purity transfer

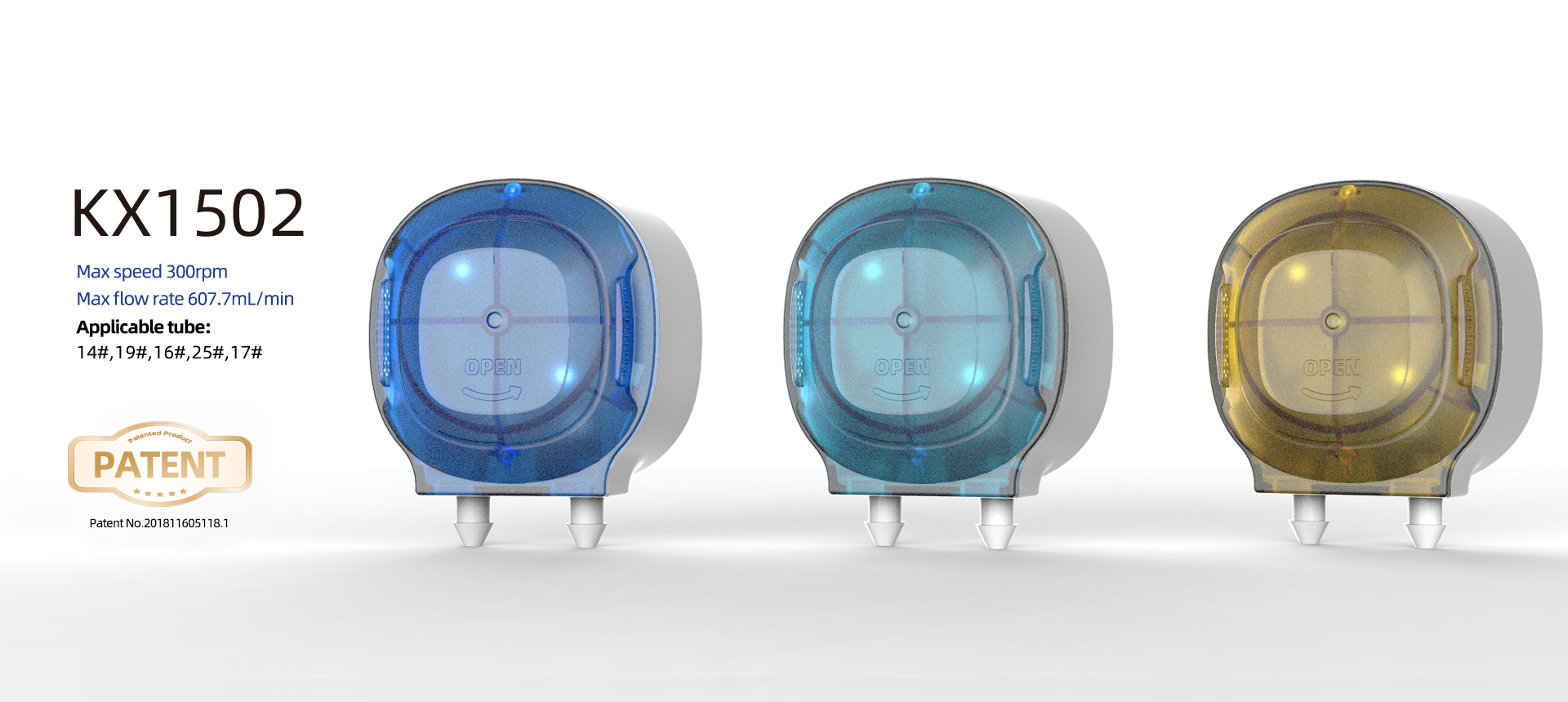

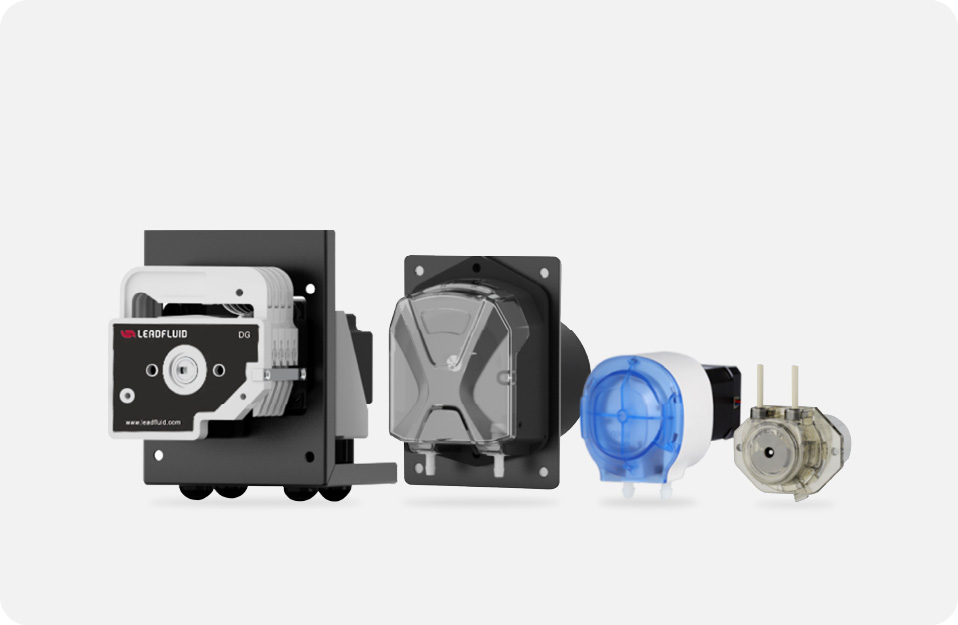

Pump Head

Peristaltic pump accessories

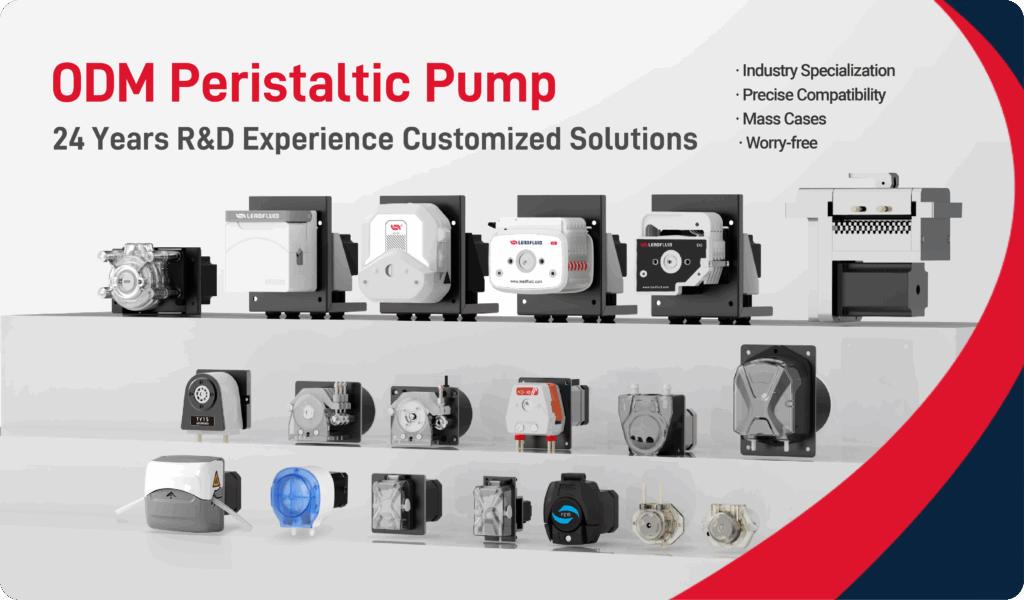

ODM Pump

Custom your fluid transfer solutions

Accessory

Compact tools – Simplifying your operations

Learn More

Get more details of Lead Fluid products

ABOUT LEAD FLUID

Seamlessly bridging solutions to application scenarios with our elite technical team

Lead Fluid (Baoding) Intelligent Equipment Manufacturing Co.,Ltd. has been dedicated to pioneering research and innovation in small-scale precision pump products.We have positioned ourselves in the global high-end market, providing customers with professional and agile technical services through a comprehensive service system. With an exceptional technical team, we seamlessly tailor solutions to various application scenarios.Our products find wide application in biotechnology, environmental protection, smart manufacturing, new energy, and other technical fields for high-precision fluid transmission and control. All our products have obtained CE and ROHS certifications and are exported to countries such as the United States, Germany, France, the Netherlands, ltaly, and Spain, earning widespread trust and praise from customers.

Lead Fluid sincerely hopes to move forward hand in hand with users and friends, bravely climb the peak, and create a better future.

Lead Fluid (Baoding) Intelligent Equipment Manufacturing Co.,Ltd.has been dedicated to pioneering research and innovation in small-scale precision pump products.We have positioned ourselves in the global high-end market, providing customers with professional and agile technical services through a comprehensive service system. With an exceptional technical team, we seamlessly tailor solutions to various application scenarios.Our products find wide application in biotechnology, environmental protection, smart manufacturing, new energy, and other technical fields for high-precision fluid transmission and control. All our products have obtained CE and ROHS certifications and are exported to countries such as the United States, Germany, France, the Netherlands, ltaly, and Spain, earning widespread trust and praise from customers.

Lead Fluid sincerely hopes to move forward hand in hand with users and friends, bravely climb the peak, and create a better future.

Lead Fluid (Baoding) Intelligent Equipment Manufacturing Co.,Ltd.has been dedicated to pioneering research and innovation in small-scale precision pump products.We have positioned ourselves in the global high-end market, providing customers with professional and agile technical services through a comprehensive service system. With an exceptional technical team, we seamlessly tailor solutions to various application scenarios.Our products find wide application in biotechnology, environmental protection, smart manufacturing, new energy, and other technical fields for high-precision fluid transmission and control. All our products have obtained CE and ROHS certifications and are exported to countries such as the United States, Germany, France, the Netherlands, ltaly, and Spain, earning widespread trust and praise from customers.

Lead Fluid sincerely hopes to move forward hand in hand with users and friends, bravely climb the peak, and create a better future.

Lead Fluid (Baoding) Intelligent Equipment Manufacturing Co.,Ltd. has been dedicated to pioneering research and innovation in small-scale precision pump products.We have positioned ourselves in the global high-end market, providing customers with professional and agile technical services through a comprehensive service system. With an exceptional technical team, we seamlessly tailor solutions to various application scenarios.Our products find wide application in biotechnology, environmental protection, smart manufacturing, new energy, and other technical fields for high-precision fluid transmission and control. All our products have obtained CE and ROHS certifications and are exported to countries such as the United States, Germany, France, the Netherlands, ltaly, and Spain, earning widespread trust and praise from customers.

Lead Fluid sincerely hopes to move forward hand in hand with users and friends, bravely climb the peak, and create a better future.

APPLICATION FIELDS

Widely used. Consistently praised. Highly recognized

Blopharmaceutical is an industry applying biotechnology and biochemical techniques, utilizing techniques such as blologic fermentation, cell culture, genetic recombination, and protein engineering to manufacture pharmaceutical products.Peristaltic pumps, with their precise and stable fluid control, lack of contamination or residue, low shear force, and easy maintenance, have become key technology in biopharmaceutical.They play a crucial role in various stages such as IVD diagnostics, chemical pharmaceuticals, coating and and purification transfer.

Since their invented, peristaltic pumps have been widely used in medical apparatus and instruments due to their characteristics of cleanliness, no dead angles, easy cleaning, and easy disinfection. They are applied in various medical procedures such as blood dialysis, infusion,various surgical rinses, and nasal feeding. With the development of peristaltic pumps, they have not only retained their original characteristics but have also evolved to possess high precision, rellability, controllability, safety, versatility, and ease of maintenance. They are extensively applied in the medical field, providing significant support for research,production, and clinical applications.

The cantrol of small-scale fluld is hindering the upgrade of industrial sutomation, impeding technologlcal progress in traditional manufacturing. Achieving online monitoring, online control, and precise control of micrafluldics poses a technological barrier that traditional manufacturing upgrades cannot avaid. Peristaitic pumps are widely utilized in various fields such as chemical and automation, owing to their characteristics of small flow rate, self-priming, and no backflow. With precise and stable fluld control, stabluty in small flow rate transfer, accurate continuoas transmission, and easy maintenance, peristaltic pumps have become key technology in the field of industrial automation.

Analytical instrument is a branch of scientific instruments.With the advancement of science and technology,particuLarly in the fields of life sciences, materials science, environmental sclence, energy science, and increasing demands for on-site and online detection,analytical instruments becoming more portabllity, minlaturization,and diversification. Peristaltic pumps are used for precise and stable fluid delivery, ensuring accurate flow control and mixing.Their unique principle prevents cross-contamination,making them essential in high-precislon, small-volume analytical instruments like blochemical analyzers and mass spectrometers.

The environmental protection industry has evolved into a comprehensive sector, encompassing areas like conservation and sustainable resource use. Globally, it’s a rapidly growing sector, serving as a key driver for industrial economic benefits.It’s also a focal point for countries aiming to innovate and adjust industrial structures. Peristaltic pumps offer high precision,stability, corrosion resistance, low shear force, and energy efficiency, making them essential in environmental protection for sustainable solutions in pollution treatment,resource management, and environmental monitoring.

Peristaltic pumps are vital in mining for transferring abrasive slurries, viscous reagents, and corrosive chemicals. Their unique design, where only the tube contacts the fluid, ensures exceptional resistance to wear and clogging. This makes them ideal for precise dosing in mineral processing, flotation reagent addition, and wastewater treatment. Key advantages include minimal maintenance, self-priming capability, and accurate flow control, significantly enhancing operational efficiency and safety in demanding mining environments.

Blopharmaceutical is an industry applying biotechnology and biochemical techniques, utilizing techniques such as blologic fermentation, cell culture, genetic recombination, and protein engineering to manufacture pharmaceutical products.Peristaltic pumps, with their precise and stable fluid control, lack of contamination or residue, low shear force, and easy maintenance, have become key technology in biopharmaceutical.They play a crucial role in various stages such as IVD diagnostics, chemical pharmaceuticals, coating and and purification transfer.

Since their invented, peristaltic pumps have been widely used in medical apparatus and instruments due to their characteristics of cleanliness, no dead angles, easy cleaning, and easy disinfection. They are applied in various medical procedures such as blood dialysis, infusion,various surgical rinses, and nasal feeding. With the development of peristaltic pumps, they have not only retained their original characteristics but have also evolved to possess high precision, rellability, controllability, safety, versatility, and ease of maintenance. They are extensively applied in the medical field, providing significant support for research,production, and clinical applications.

The cantrol of small-scale fluld is hindering the upgrade of industrial sutomation, impeding technologlcal progress in traditional manufacturing. Achieving online monitoring, online control, and precise control of micrafluldics poses a technological barrier that traditional manufacturing upgrades cannot avaid. Peristaitic pumps are widely utilized in various fields such as chemical and automation, owing to their characteristics of small flow rate, self-priming, and no backflow. With precise and stable fluld control, stabluty in small flow rate transfer, accurate continuoas transmission, and easy maintenance, peristaltic pumps have become key technology in the field of industrial automation.

Analytical instrument is a branch of scientific instruments.With the advancement of science and technology,particuLarly in the fields of life sciences, materials science, environmental sclence, energy science, and increasing demands for on-site and online detection,analytical instruments becoming more portabllity, minlaturization,and diversification. Peristaltic pumps are used for precise and stable fluid delivery, ensuring accurate flow control and mixing.Their unique principle prevents cross-contamination,making them essential in high-precislon, small-volume analytical instruments like blochemical analyzers and mass spectrometers.

The environmental protection industry has evolved into a comprehensive sector, encompassing areas like conservation and sustainable resource use. Globally, it’s a rapidly growing sector, serving as a key driver for industrial economic benefits.It’s also a focal point for countries aiming to innovate and adjust industrial structures. Peristaltic pumps offer high precision,stability, corrosion resistance, low shear force, and energy efficiency, making them essential in environmental protection for sustainable solutions in pollution treatment,resource management, and environmental monitoring.

Peristaltic pumps are vital in mining for transferring abrasive slurries, viscous reagents, and corrosive chemicals. Their unique design, where only the tube contacts the fluid, ensures exceptional resistance to wear and clogging. This makes them ideal for precise dosing in mineral processing, flotation reagent addition, and wastewater treatment. Key advantages include minimal maintenance, self-priming capability, and accurate flow control, significantly enhancing operational efficiency and safety in demanding mining environments.

Peristaltic pumps are ideal for food and beverage processing, handling sensitive fluids like dairy products, juices, sauces, and beverages without contamination. Their gentle pumping action preserves product integrity, while the closed-tube system ensures hygiene and easy cleaning. Applications include precise ingredient dosing, flavor addition, and CIP systems. Advantages include sanitary design, minimal maintenance, and accurate metering, supporting efficient and compliant food production.

Peristaltic pumps play a critical role in materials preparation, expertly handling sensitive or high-viscosity fluids such as nanomaterials, ceramic slurries, polymer solutions, and abrasive particles. Their contamination-free transfer ensures material purity, while precise flow control guarantees consistent chemical ratios and coating thickness. Widely used in battery slurry coating, composite material mixing, precision spraying, and lab R&D, these pumps offer excellent sealing, corrosion resistance, and repeatable metering accuracy, providing reliable support for advanced material development and production.

NEW PRODUCT RECOMMENDATIONS

Reshaping the boundaries of precision with technology

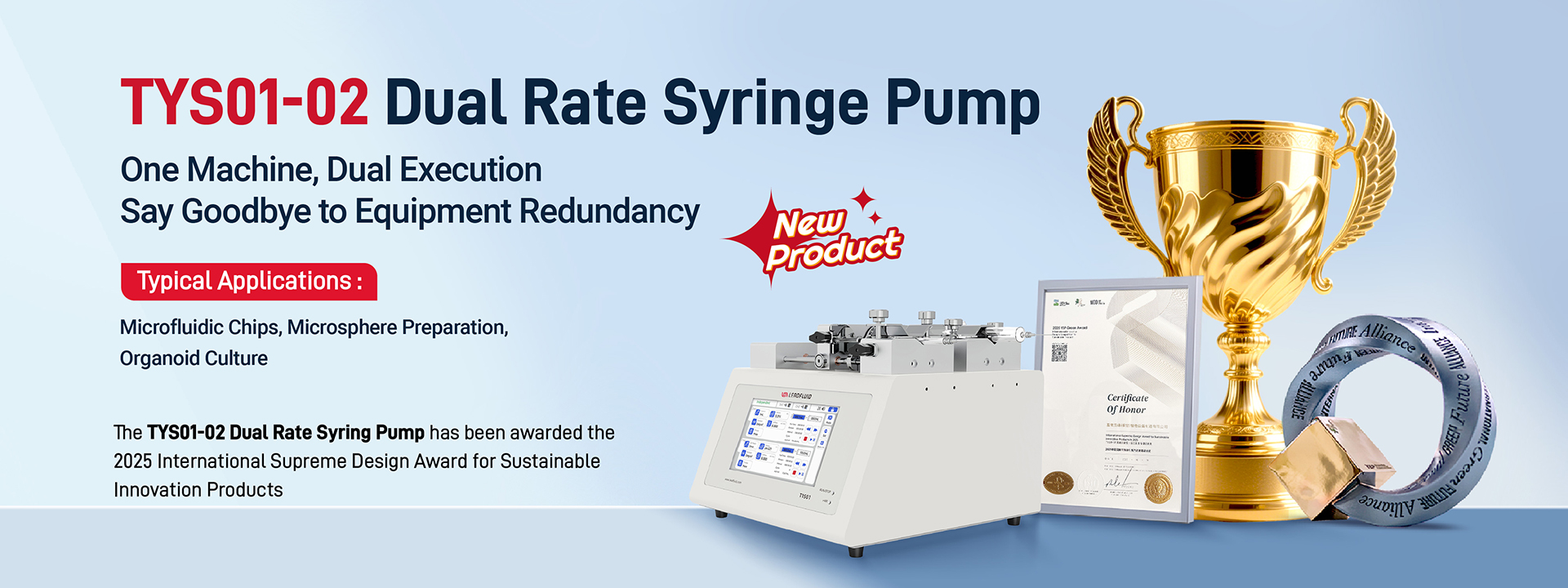

New Product

TYS01-02

Dual Rate Syringe Pump

Flow range: 8pL/min-150.147mL/min

Syringe size: 0.5μL-100mL

New Product

G3030

Industrial Syringe Pump

Flow range: 0.0005mL/min-250mL/min

Syringe size: 50μL-5mL

New Product

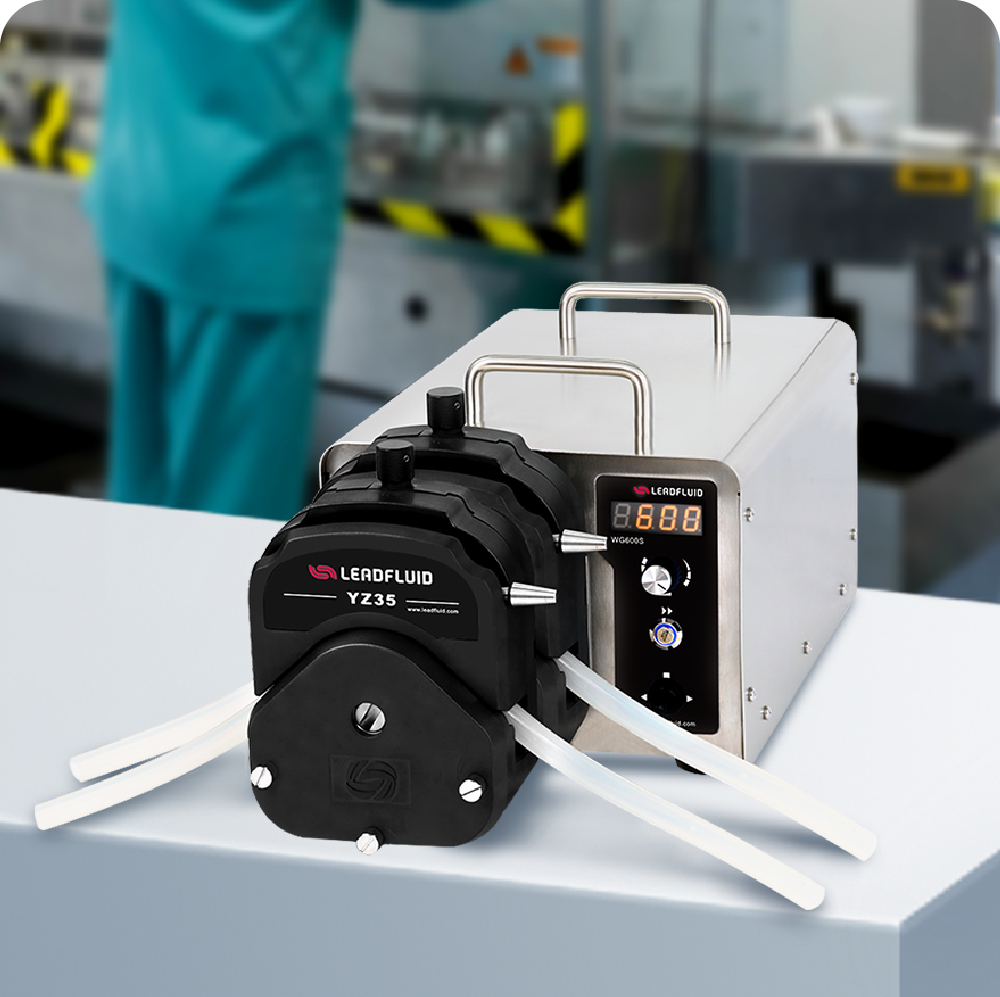

WG600S

Industrial Peristaltic Pump

Flow range:

0.001-13.2L/min

Channel: 1/2 channels

New Product

TYS01-02

Dual Rate Syringe Pump

Flow range: 8pL/min-150.147mL/min

Syringe size: 0.5μL-100mL

New Product

G3030

Industrial Micro-Syringe Pump

Flow range: 0.0005mL/min-250mL/min

Syringe size: 50μL-5mL

New Product

DS600

Peristaltic Pump Filling System

Flow range: 0.005-3000mL/min

Channel: 3-32 channels

New Product

WG600S

Industrial Peristaltic Pump

Flow range: 0.001-13.2L/min

Channel: 1/2 channels

MOST POPULAR

Born from innovation, proven by performance, and chosen by experts like you

BT103S

Speed-Variable Peristaltic Pump

Flow range: 0.00011-500mL/min

Channel: 1/2/4 channels

BT301L

Intelligent Flow Peristaltic Pump

Flow range: 0.005-1750mL/min

Channel: 1/2 channels

MF106

High-protection Peristaltic Pump

Flow range: 0.005-7800mL/min

Channel: 1/2/4 channels

TFD01-01

Laboratory Syringe Pump

Flow range: 0.058 nL/min – 1.587mL/min

Channel: 1 channel

BT103S

Speed-Variable Peristaltic Pump

Flow range: 0.00011-500mL/min

Channel: 1/2/4 channels

BT301L

Intelligent Flow Peristaltic Pump

Flow range: 0.005-1750mL/min

Channel: 1/2 channels

MF106

High-protection Peristaltic Pump

Flow range: 0.005-7800mL/min

Channel: 1/2/4 channels

INDUSTRY SOLUTIONS

Provide you with verified, efficient, and durable solutions

Column Injection

Chromatography, also known as chromatography, is a method of separating and measuring multi-component mixtures by using the different physical properties of each component. It is particularly suitable for the separation and determination of biological macromolecules such as proteins and nucleic acids.

Reference pump

BT100L/YZ15T 14# silicone tube

BT101S/YZ15T 14# silicone tube

Brain Stereotaxic Instrument

A stereotaxic device, also known as a brain fixation device, uses a three-dimensional coordinate system defined by a marker or other reference point outside the skull to determine the location of certain subcortical neural structures so that they can be stimulated, destroyed, injected with drugs, guided with potentials, etc. without direct visual exposure.

Reference pump

Bio-fementation

Chromatography, also known as chromatography, is a method of separating and measuring multi-component mixtures by using the different physical properties of each component. It is particularly suitable for the separation and determination of biological macromolecules such as proteins and nucleic acids.

Reference pump

Glue Dosing

Gear pump dosing or transfer high viscosity liquid transfer, pulseless transfer, cosmetics or glue liquid. It gives constant and smoothly transferring.

Reference pump

Column Injection

Chromatography, also known as chromatography, is a method of separating and measuring multi-component mixtures by using the different physical properties of each component. It is particularly suitable for the separation and determination of biological macromolecules such as proteins and nucleic acids.

Reference pump

BT100L/YZ15T 14# silicone tube

BT101S/YZ15T 14# silicone tube

Brain Stereotaxic Instrument

A stereotaxic device, also known as a brain fixation device, uses a three-dimensional coordinate system defined by a marker or other reference point outside the skull to determine the location of certain subcortical neural structures so that they can be stimulated, destroyed, injected with drugs, guided with potentials, etc. without direct visual exposure.

Reference pump

Bio-fementation

Chromatography, also known as chromatography, is a method of separating and measuring multi-component mixtures by using the different physical properties of each component. It is particularly suitable for the separation and determination of biological macromolecules such as proteins and nucleic acids.

Reference pump

Glue Dosing

Gear pump dosing or transfer high viscosity liquid transfer, pulseless transfer, cosmetics or glue liquid. It gives constant and smoothly transferring.

Reference pump

FEATURED CLIENTS

NEWS & INFORMATION

MF103 Core Analysis丨What “Hard Power” Lies Within Its Compact Body?

MF103 Core Analysis丨What “Hard Power” Lies Within Its Compact Body?In the previous article, we gained an initial understanding of the MF103 High‑Protection Peristaltic Pump. Today, let’s take a closer look inside this compact unit to uncover the core design features and technical details that make it powerful. 01“Armor Body” Die‑Cast Aluminum × Anti‑Corrosive Coating (Die‑cast aluminum integrated housing) (Anti‑corrosive surface coating) A solid foundation… Read More »MF103 Core Analysis丨What “Hard Power” Lies Within Its Compact Body?

New Product Launch | Lead Fluid’s High-Protection Series — MF103

New Product Launch | Lead Fluid’s High-Protection Series — MF103Real‑World Conditions Are Tough—and Unforgiving Frequent cleaning and sterilization, hot and humid splashing, confined spaces, airborne dust, and corrosive aerosols…In such environments, equipment must deliver not only precision, but also stability, durability, and compactness. The Lead Fluid MF103 High‑Protection…

Lead Fluid 2025 Year in Review: Reaching Upwards, Taking Root in Stability

Lead Fluid 2025 Year in Review: Reaching Upwards, Taking Root in StabilitySpring grows, summer thrives, autumn harvests, and winter stores away another year quietly draws to a close.Standing at the turn of time, we look back on a road that was far from smooth, yet truly worthwhile.In 2025, Lead Fluid advanced…

Definition and Development of Peristaltic Pumps

Definition and Development of Peristaltic PumpsA peristaltic pump, also known as a hose pump or dosing pump, is a device that transports fluids by alternately compressing an elastic tube. Its operating principle is similar to the peristaltic movement of the human intestine: rollers or…

Peristaltic Pump Maintenance Guide: Extend Equipment Life and Ensure Stable Operation

Peristaltic Pump Maintenance Guide: Extend Equipment Life and Ensure Stable OperationPeristaltic pumps, known for their high precision and contamination-free fluid transfer, are widely used in pharmaceutical, food, chemical, and environmental industries. With a simple structure and easy maintenance, they require proper care to ensure long-term stable operation. This article…

FEATURED PRODUCTS

Peristaltic Pump

Contaminant-free flow by tubecompression

Syringe Pump

Delivers ultra-precisemicro-volume injection

Gear Pump

High-viscosity, high-pressurefluid transfer

Filling System

Contaminant-free flow by tube compression

ODM Pump

Custom your fluid transfer solutions

ABOUT LEAD FLUID

Lead Fluid (Baoding) Intelligent Equipment Manufacturing Co.,Ltd. has been dedicated to pioneering research and innovation in small-scale precision pump products.We have positioned ourselves in the global high-end market, providing customers with professional and agile technical services through a comprehensive service system. With an exceptional technical team, we seamlessly tailor solutions to various application scenarios.Our products find wide application in biotechnology, environmental protection, smart manufacturing, new energy, and other technical fields for high-precision fluid transmission and control. All our products have obtained CE and ROHS certifications and are exported to countries such as the United States, Germany, France, the Netherlands, ltaly, and Spain, earning widespread trust and praise from customers.

Lead Fluid sincerely hopes to move forward hand in hand with users and friends, bravely climb the peak, and create a better future.

APPLICATION FIELDS

Blopharmaceutical is an industry applying biotechnology and biochemical techniques, utilizing techniques such as blologic fermentation, cell culture, genetic recombination, and protein engineering to manufacture pharmaceutical products.Peristaltic pumps, with their precise and stable fluid control, lack of contamination or residue, low shear force, and easy maintenance, have become key technology in biopharmaceutical.They play a crucial role in various stages such as IVD diagnostics, chemical pharmaceuticals, coating and and purification transfer.

Since their invented, peristaltic pumps have been widely used in medical apparatus and instruments due to their characteristics of cleanliness, no dead angles, easy cleaning, and easy disinfection. They are applied in various medical procedures such as blood dialysis, infusion,various surgical rinses, and nasal feeding. With the development of peristaltic pumps, they have not only retained their original characteristics but have also evolved to possess high precision, rellability, controllability, safety, versatility, and ease of maintenance. They are extensively applied in the medical field, providing significant support for research,production, and clinical applications.

The cantrol of small-scale fluld is hindering the upgrade of industrial sutomation, impeding technologlcal progress in traditional manufacturing. Achieving online monitoring, online control, and precise control of micrafluldics poses a technological barrier that traditional manufacturing upgrades cannot avaid. Peristaitic pumps are widely utilized in various fields such as chemical and automation, owing to their characteristics of small flow rate, self-priming, and no backflow. With precise and stable fluld control, stabluty in small flow rate transfer, accurate continuoas transmission, and easy maintenance, peristaltic pumps have become key technology in the field of industrial automation.

Analytical instrument is a branch of scientific instruments.With the advancement of science and technology,particuLarly in the fields of life sciences, materials science, environmental sclence, energy science, and increasing demands for on-site and online detection,analytical instruments becoming more portabllity, minlaturization,and diversification. Peristaltic pumps are used for precise and stable fluid delivery, ensuring accurate flow control and mixing.Their unique principle prevents cross-contamination,making them essential in high-precislon, small-volume analytical instruments like blochemical analyzers and mass spectrometers.

The environmental protection industry has evolved into a comprehensive sector, encompassing areas like conservation and sustainable resource use. Globally, it’s a rapidly growing sector, serving as a key driver for industrial economic benefits.It’s also a focal point for countries aiming to innovate and adjust industrial structures. Peristaltic pumps offer high precision,stability, corrosion resistance, low shear force, and energy efficiency, making them essential in environmental protection for sustainable solutions in pollution treatment,resource management, and environmental monitoring.

Peristaltic pumps are vital in mining for transferring abrasive slurries, viscous reagents, and corrosive chemicals. Their unique design, where only the tube contacts the fluid, ensures exceptional resistance to wear and clogging. This makes them ideal for precise dosing in mineral processing, flotation reagent addition, and wastewater treatment. Key advantages include minimal maintenance, self-priming capability, and accurate flow control, significantly enhancing operational efficiency and safety in demanding mining environments.

Peristaltic pumps are ideal for food and beverage processing, handling sensitive fluids like dairy products, juices, sauces, and beverages without contamination. Their gentle pumping action preserves product integrity, while the closed-tube system ensures hygiene and easy cleaning. Applications include precise ingredient dosing, flavor addition, and CIP systems. Advantages include sanitary design, minimal maintenance, and accurate metering, supporting efficient and compliant food production.

Peristaltic pumps play a critical role in materials preparation, expertly handling sensitive or high-viscosity fluids such as nanomaterials, ceramic slurries, polymer solutions, and abrasive particles. Their contamination-free transfer ensures material purity, while precise flow control guarantees consistent chemical ratios and coating thickness. Widely used in battery slurry coating, composite material mixing, precision spraying, and lab R&D, these pumps offer excellent sealing, corrosion resistance, and repeatable metering accuracy, providing reliable support for advanced material development and production.

NEW PRODUCTS

New Product

TYS01-02

Dual Rate Syringe Pump

Flow range: 8pL/min-150.147mL/min

Syringe size: 0.5μL-100mL

New Product

G3030

Industrial Micro-Syringe Pump

Flow range: 0.0005mL/min-250mL/min

Syringe size: 50μL-5mL

New Product

DS600

Peristaltic Pump Filling System

Flow range: 0.005-3000mL/min

Channel: 3-32 channels

New Product

WG600S

Industrial Peristaltic Pump

Flow range: 0.001-13.2L

Channel: 1/2 channels

MOST POPULAR

INDUSTRY SOLUTIONS

Column Injection

Chromatography, also known as chromatography, is a method of separating and measuring multi-component mixtures by using the different physical properties of each component. It is particularly suitable for the separation and determination of biological macromolecules such as proteins and nucleic acids.

Reference pump

BT100L/YZ15T 14# silicone tube

BT101S/YZ15T 14# silicone tube

Brain Stereotaxic Instrument

A stereotaxic device, also known as a brain fixation device, uses a three-dimensional coordinate system defined by a marker or other reference point outside the skull to determine the location of certain subcortical neural structures so that they can be stimulated, destroyed, injected with drugs, guided with potentials, etc. without direct visual exposure.

Reference pump

Bio-fementation

Chromatography, also known as chromatography, is a method of separating and measuring multi-component mixtures by using the different physical properties of each component. It is particularly suitable for the separation and determination of biological macromolecules such as proteins and nucleic acids.

Reference pump

Glue Dosing

Gear pump dosing or transfer high viscosity liquid transfer, pulseless transfer, cosmetics or glue liquid. It gives constant and smoothly transferring.

Reference pump

FEATURED CLIENTS

NEWS & INFORMATION

MF103 Core Analysis丨What “Hard Power” Lies Within Its Compact Body?

MF103 Core Analysis丨What “Hard Power” Lies Within Its Compact Body?In the previous article, we gained an initial understanding of the MF103 High‑Protection Peristaltic Pump. Today, let’s take a closer look inside this compact unit to uncover the core design features and technical details that make it powerful. 01“Armor Body” Die‑Cast Aluminum × Anti‑Corrosive Coating (Die‑cast aluminum integrated housing) (Anti‑corrosive surface coating) A solid foundation… Read More »MF103 Core Analysis丨What “Hard Power” Lies Within Its Compact Body?

Our team is ready to help you

For product enquires or technical advice

please send emial to

master@leadfluid.com

or