Introduction

• This pump head has a simple structure, high cost performance and small transmission pulsation.

• Small size, compact structure, beautiful appearance.

• Low operating noise.

• The shell is made of transparent polycarbonate (PC), allowing you to observe the internal conditions during operation.

• The roller is made of S30408 stainless steel, which is corrosion-resistant.

• Suitable for high speed continuous operation.

• Universal installation dimensions, can be used in cascade.

• Suitable for applications with small and medium flow rates, and can be used in equipment, instruments, and laboratories.

Parameters

Motor Type: 57 stepper motor

Drive and Control Method: Customer Provided

Speed Range: ≤600rpm

Channel Number: 1

Number of Rollers: 3 rollers

Rotation Direction: Clockwise/Counterclockwise rotation

Type of Tube: Silicone, Pharmed, A-60-G

Method of Tube Installation: Built-in

Pressure Tube Type: Fixed clearance

Pump Head Shell Material: PC

Pump Head Roller Material: S30408 stainless steel

Life: ≥4000h

Noise: ≤60dB (test environment noise ≤40dB, test product and noise meter horizontal distance of 1 meter)

Weight: 1.683kg (excluding tube)

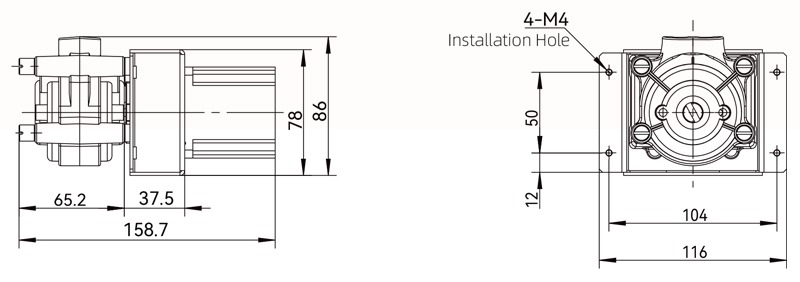

Dimensions: (L×W×H) 178.7*116*86(mm)

Wattage: ≤30W

Working Environment: Temperature 0- 40°C, relative humidity<80% RH

Storage Environment: Ambient temperature of -40 ~ +50 °C, relative humidity of not more than 95% of the clean and well-ventilated

environment, the air shall not contain corrosive, flammable gases, oil mist, dust.

Suitable Tube Model and Flow Rate Reference

| Model | Material of Tube | Suitable Tube | 10rpm Flow Rate | 100rpm Flow Rate | 300rpm Flow Rate | 600rpm Flow Rate |

| B600K0BZ15-16 | Silicone tube | 16# | 8.7 | 87 | 261 | 522 |

| B600K0BZ25-24 | Silicone tube | 24# | 26 | 260 | 780 | 1560 |

The above data is obtained from the test of purified water with a Lead Fluid tube under normal and pressure conditions in the laboratory. This data is for reference only.

Due to pressure in actual use , temperature, medium characteristics, tube material and other specific factors, the specific situation needs to consult our engineers.

Product Structure & Usage Method

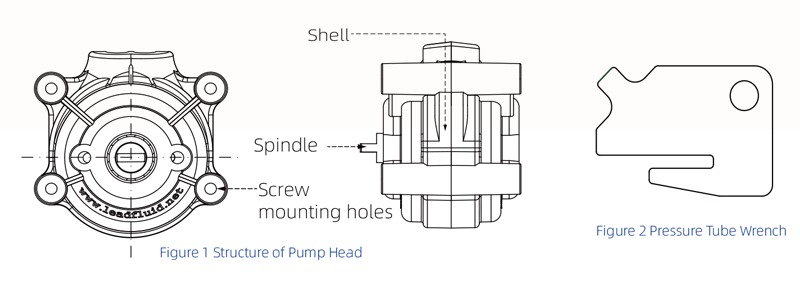

Component Name and Function

1.Shell: Support structure

2.Spindle: Connected to the drive

3.Screw Mounting Holes: Fix the pump head

Note: The product is equipped with a pump tube pressure wrench, a 300mm silicone tube, and four single-channel mounting screws.

Usage Method

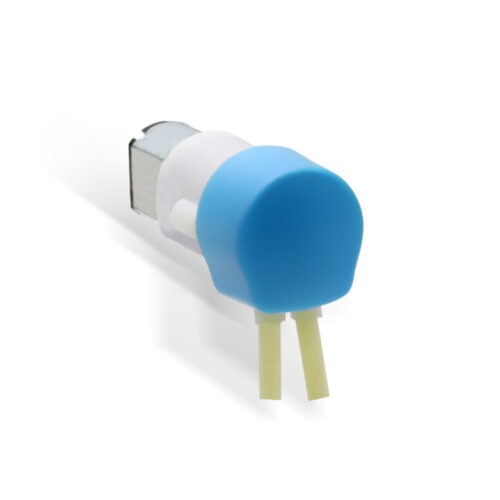

Tube Installation

• Open the pump head shell and press the tube with pressure wrench according to the position shown in the figure. (figure 3)

• Turn the tube pressure wrench counterclockwise to insert the tube between the roller and pump shell.(figure 4)

• After snapping on the remaining part of pump shell, turn the spindle with the pressure wrench as shown to adjust the position of the tube

in the shell. (figure 5)

Pump Head Installation

• Insert the protruding end of the pump head’s main spindle (the flat spindle portion) into the groove inside the drive, in the coupling,

and then secure it with screws.

Dimension

unit: mm