Introduction

• The shell is made of PA66 material with high strength.

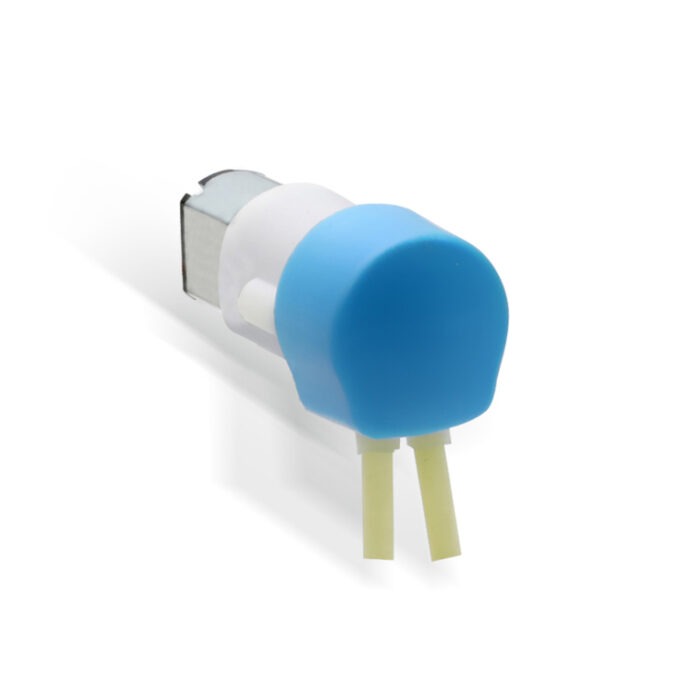

• Adopting compact structure design, small volume and light weight.

• Using a 3.7V micro DC reduction motor, low noise, low energy consumption, and can be driven by dry battery.

• Mostly used for small household appliances, small testing equipment.

• Used for micro flow.

• For intermittent operation use.

Parameters

Motor Type: DC reduction motor

Power Supply: DC3.7V

Fixed Speed: 20rpm, 200rpm

Channel Number: 1

Number of Rollers: 2 rollers

Rotation Direction: Clockwise/Counterclockwise rotation

Material of Tube: Silicone, Pharmed

Method of Tube Installation: Tube stopper

Pressure Tube Type: Fixed clearance

Pump Head Shell Material: PA66

Pump Head Roller Material: PTFE

Pump Head Roller Shaft Material: S30408 stainless steel

Pump Head Life: ≥200h

Noise: ≤60dB (test environment noise ≤40dB, test product and noise meter horizontal distance of 1 meter)

Weight: Approx. 15g (with DC reduction motor and 13.5cm silicone tube)

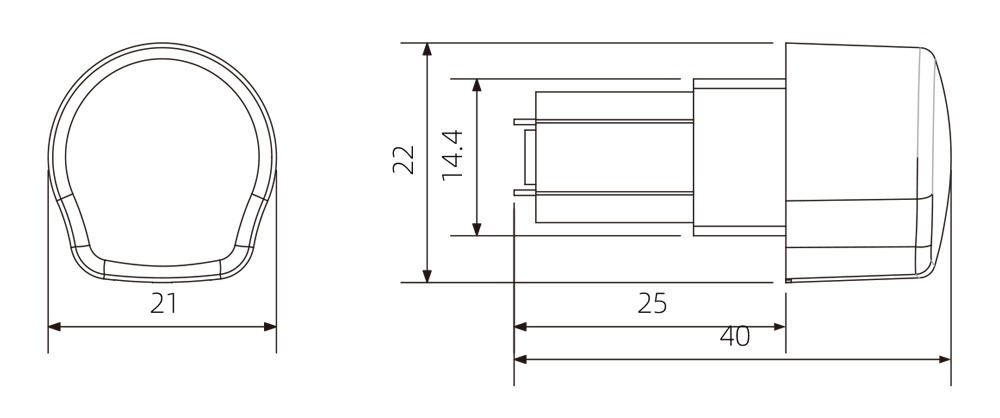

Dimensions: (L×W×H) 40*21*22(mm)

Working Environment: Temperature 0- 40°C, relative humidity<80% RH

Storage Environment: Ambient temperature of -20 ~ +50 ℃, relative humidity of not more than 95% of the clean and

well-ventilated environment, the air shall not contain corrosive, flammable gases, oil mist, dust.

Suitable Tube Model and Flow Rate Reference

| Model | Speed | Material of Tube | Suitable Tube | Wall Thickness | ID | Maximum Flow |

| Z020A2WX09 | 20rpm | Silicone tube | 2×3.84×0.92mm | 0.92mm | 2mm | 1.5mL/min |

| Z200A2WX09 | 200rpm | Silicone tube | 2×3.84×0.92mm | 0.92mm | 2mm | 1.5mL/min |

The above data is obtained from the test of purified water with a Lead Fluid tube under normal and pressure conditions in the laboratory.

This data is for reference only.

Due to pressure in actual use, temperature, medium characteristics, tube material and other specific factors, the specific situation needs to consult our engineers.

Product Structure & Usage Method

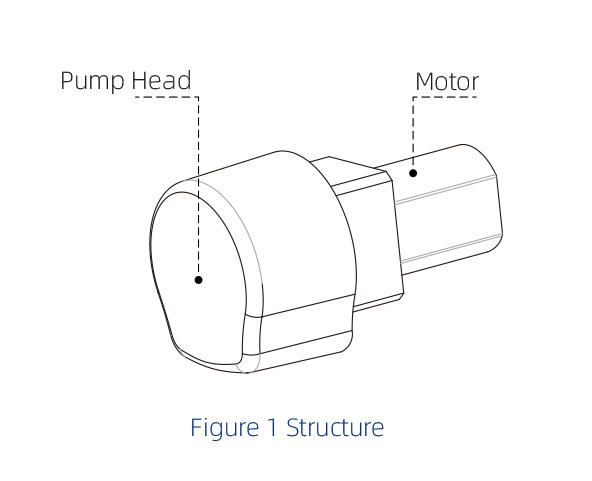

Product Structure

Component Name and Function

1.Pump Head: Installation of a tube to transfer liquid.

2.Motor: Provides power.

Usage Method

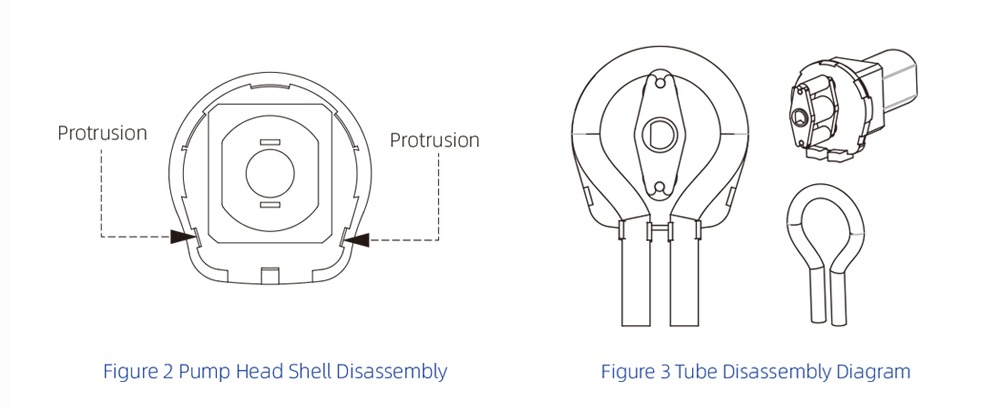

Disassembly of WX09 pump head

Step 1: Use a screwdriver to pry the pump head protrusion can be removed from the pump head shell.

Step 2: Remove the tube line as shown.

Dimension

unit:mm