Feature

• Suitable for conveying fluids containing corrosive substances, high viscosity, high density, high solid content, or those sensitive to shear force;

• Using multi-layer composite tube, high transmission pressure, up to 15 Bar;

• Flow rate is stable, transmission accuracy is high;

• Fluids capable of being transmitted at temperatures up to 80°C;

• The ability for dry run and self-priming, without the need for a check valve, flushing system, and dry run protection, with a maximum suction lift up to 9 meters;

• Reversible operation, suction or discharge of blockages from the tube;

• Fluids only contact the pump tube, ensuring no contamination throughout the process, and the pump tube can be sterilized with high temperature and high pressure;

• Routine maintenance is simple and generally requires only the replacement of the pump tube.

Technical Parameter

JP100S-25

Tube diameter and length: 25x53x1005mm (inner diameter × outer diameter × length)

Max flow rate: 18 L/min (60rpm)

Traffic per minute: 12.6L

Control mode: Inverter Stepless Speed Regulation (External);Fixed rotational speed (recommended 42rpm, no need for a frequency converter)

Speed range: 10~100rpm (It is recommended to remain below 60rpm during continuous operation)

Speed resolution: 1Hz (with frequency converter)

Inlet negative pressure: ≤0.9 Bar

Outlet pressure: ≤15 Bar

Fluid temperature: <80°C

Tube material: Natural Rubber (NR) — Standard; Nitrile Butadiene Rubber (NBR); Ethylene Propylene Diene Monomer (EPDM)

Tube lifespan: 2500~3000 hours ( under normal temperature and pressure, pumping water, 45rpm )

Lubricant consumption: 2L

Effective duration of lubricants: Replace together with the tube

Connector specifications: DN32 Pagoda Joint (Stainless Steel 304)

Motor types: Variable frequency motor (standard); Explosion-proof motor (optional, with an explosion-proof rating of EXDIIBT4)

Power supply: Three-phase AC380V, 0.37 KW

Working environment: Temperature 0- 40°C Relative humidity<80%

Degree of protection: IP54

Dimensions: 688×516×460(mm)

Weight: 80kg

JP100S-32

Tube diameter and length: 32×53×1005 (inner diameter × outer diameter × length)

Max flow rate: 36 L/min (60rpm)

Traffic per minute: 25.2L

Control mode: Inverter Stepless Speed Regulation (External); Fixed rotational speed (recommended 42rpm, no need for a frequency converter)

Speed range: 10~100rpm (It is recommended to remain below 60rpm during continuous operation)

Speed resolution: 1Hz (with frequency converter)

Inlet negative pressure: ≤0.9 Bar

Outlet pressure: ≤15 Bar

Fluid temperature: <80°C

Tube material: Natural Rubber (NR) — Standard Configuration; Nitrile Butadiene Rubber (NBR); Ethylene Propylene Diene Monomer (EPDM)

Tube lifespan: 2500~3000 hours ( under normal temperature and pressure, pumping water, 42rpm )

Lubricant consumption: 2.5L

Effective duration of lubricants: Replace together with the tube

Connector specifications: DN32 Pagoda Joint (Stainless Steel 304)

Motor types: Variable frequency motor (standard); Explosion-proof motor (optional, with an explosion-proof rating of EXDIIBT4)

Power supply: Three-phase AC380V, 1.5 KW

Working environment: Temperature 0- 40°C Relative humidity<80%

Degree of protection: IP54

Dimensions: LWH 671×601×515(mm)

The overall weight of the device: 122kg

Choose the pump tube according to the characteristics of different materials; the lifespan of a pump tube decreases as the speed increases; the pump tubes made of three different

materials have the same lifespan.

Natural Rubber (NR): Commonly used due to its smooth interior and excellent wear resistance, making it suitable for transferring mildly corrosive and slurry-like materials;

Nitrile Butadiene Rubber (NBR): Made via the emulsion polymerization of butadiene and acrylonitrile, this rubber exhibits strong resistance to oils, alkalis, and detergents;

Ethylene Propylene Diene Monomer (EPDM): This material is a copolymer of ethylene, propylene, and a small quantity of non-conjugated dienes. It has outstanding chemical corrosion

resistance, making it particularly resistant to substances like ethanol and strong acids.

Flow Table

| Mode | Flow Rate Table JP100S-25 | Flow Rate Table JP100S-32 | ||

| Running state | Speed(rpm) | Flow Rate(L/min) | Speed(rpm) | Flow Rate(L/min) |

| Continuous conditions | 10 | 3 | 10 | 6 |

| 30 | 9 | 30 | 18 | |

| 42(Power Frequency) | 12.6 | 42(Power Frequency) | 25.2 | |

| 60 | 18 | 60 | 36 | |

| Intermittent conditions | 80 | 24 | 80 | 48 |

| (Work for 1 hour, rest for 1 hour) | 100 | 30 | 100 | 60 |

Data conditions: Water pumping under normal temperature and pressure; inlet and outlet tubes each 1 meter in length; no height difference between the pump and the material liquid level.

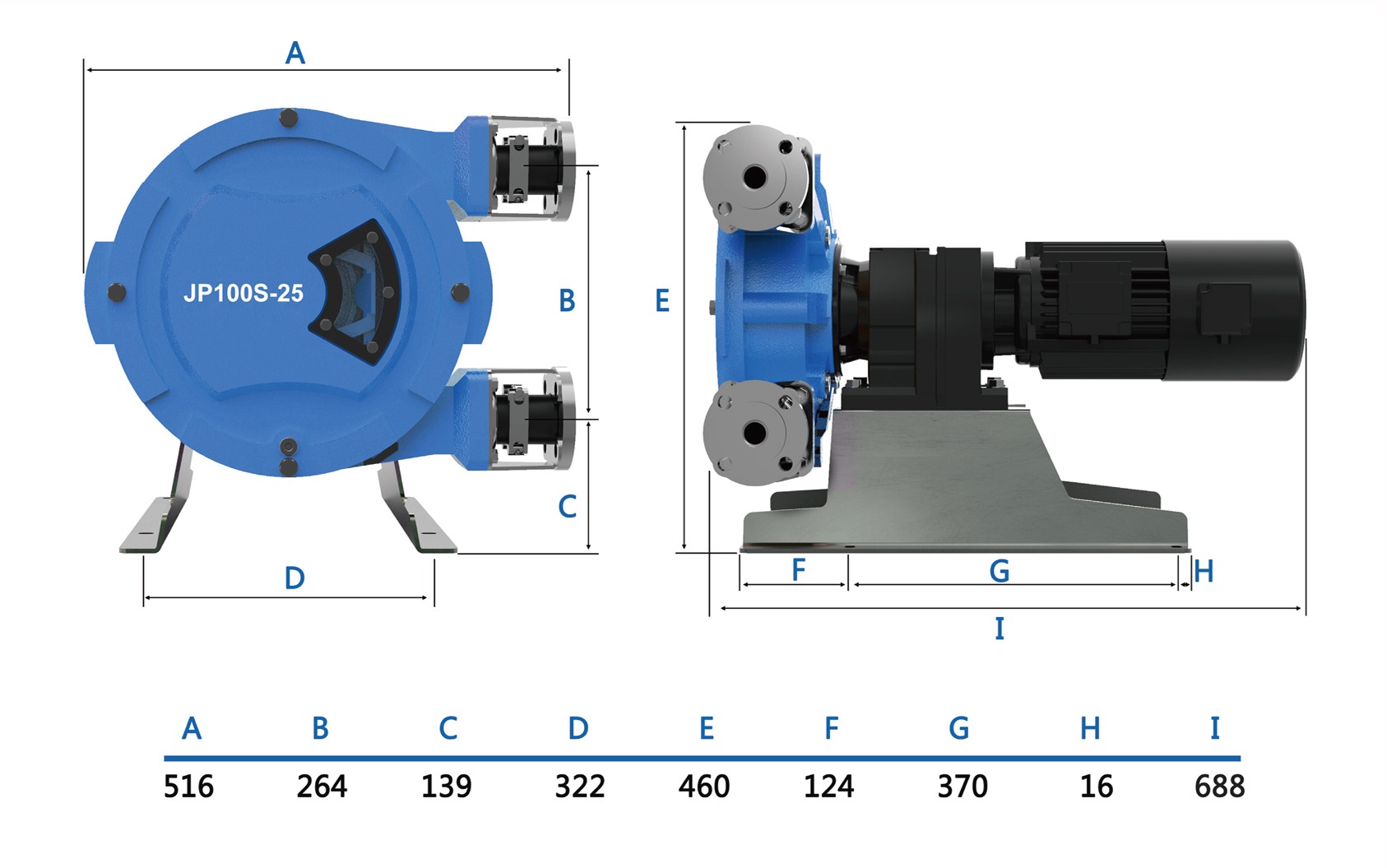

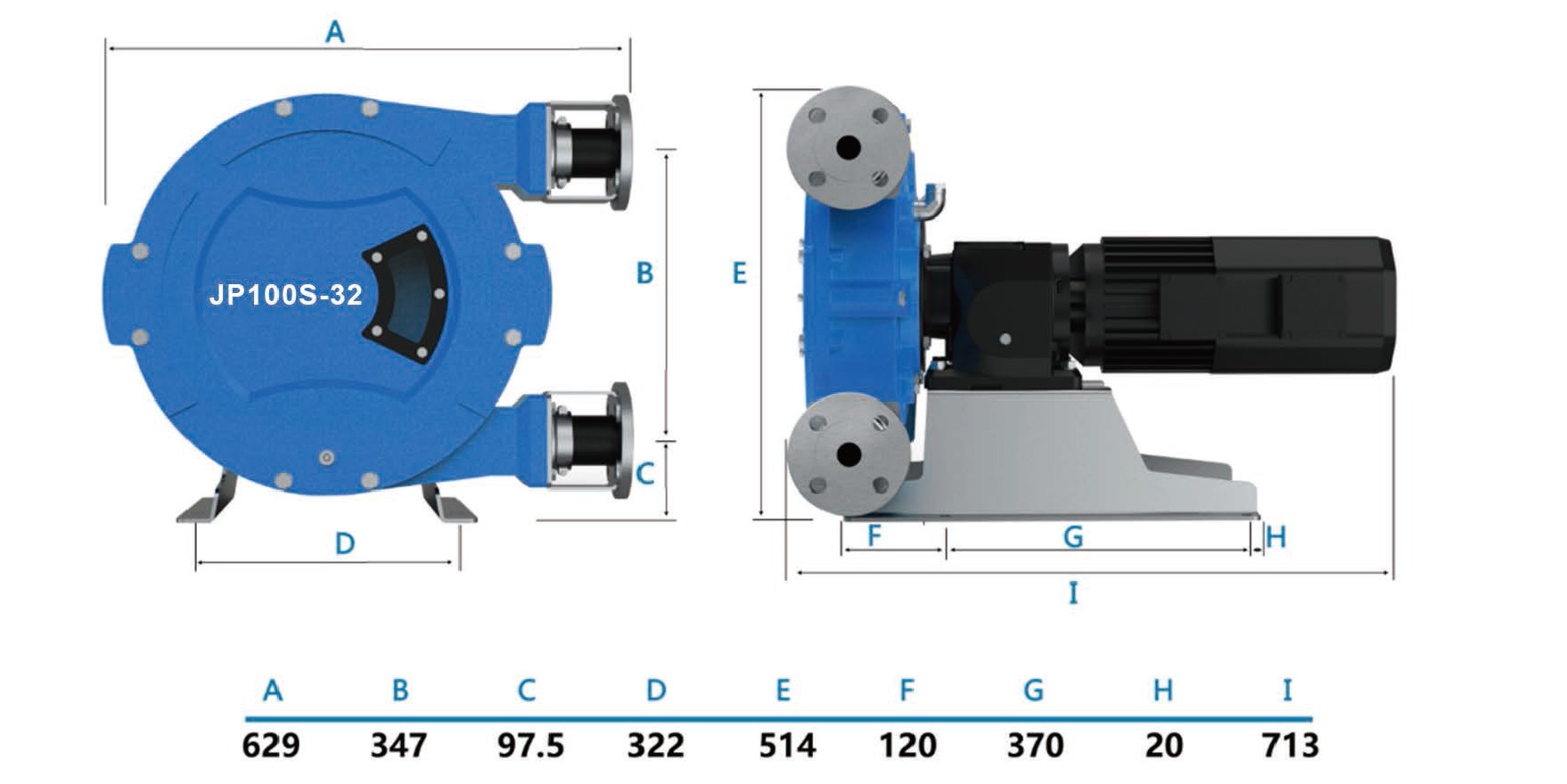

Dimensions(mm)

JP100S-25

JP100S-32

Application Fields:

Industry, environmental protection, agriculture, chemical engineering, and other sectors.

Typical Applications:

High-viscosity liquid transfer, high-solid-content liquid delivery, large-flow transportation.

Statement:The final explanation right of above information belongs to Lead Fluid.