Feature

- Suitable for conveying fluids containing corrosiveness, high viscosity, high density, high solid content or sensitive to shear.

- Multi-layer compound tube with high transfer pressure up to 10Bar.

- Stable flow, high accuracy.

- Can transfer fluids up to 80℃.

- Can run dry and self-priming, no one-way valve, flushing system and dry-running protection, and the max suction range can reach 9 meters.

- Reverse operation can suck or discharge the blockage from the pipeline.

- The fluid only touches the pump tube, no pollution in the whole process.

- Daily maintenance is simple, generally only need to replace the pump tube.

Technical Parameters

| Product Model | JP100S-40 | JP100S-50 | JP100S-65 |

| Max flow rate | 78 L/min (60rpm) | 174 L/min (optimal 60rpm) | 335 L/min (optimal 50rpm) |

| Traffic per minute | 54.6L | 122L | 281L |

| Control mode | Inverter Stepless Speed Regulation (External); Fixed rotational speed (recommended 42rpm, no need for a frequency converter) |

||

| Range | Fixed rotational speed (recommended 42rpm, no need for a frequency converter) | ||

| Speed resolution | 10~100 rpm (recommended to keep it below 60 rpm for continuous operation) | ||

| Inlet negative pressure | 1Hz (with frequency converter) | ||

| Iutlet pressure | ≤0.9 Bar | ||

| Outlet pressure | ≤15 Bar | ≤15 Bar | ≤16 Bar |

| Fluid temperature | <80℃ | ||

| Tube Material | Natural Rubber (NR) — Standard Configuration; Nitrile Butadiene Rubber (NBR); Ethylene Propylene Diene Monomer (EPDM) |

||

| Tube lifespan | 2500~3000 hours ( under normal temperature and pressure, pumping water, 42rpm ) | ||

| Lubricant Consumption | 5L | 10L | 25L |

| Effective Duration of Lubricants | Replace together with the tube | ||

| Connector Specifications | DN40 stainless steel 304 flange | DN50 stainless steel 304 flange | 2-1/2″flange(stainless steel 304) |

| Motor Types | AC gear motor (standard model); Explosion-proof motor (optional, with an explosion-proof rating of EXDIIBT4) |

||

| Power Supply | Three-phase AC380V, 4 KW | Three-phase AC380V, 5.5KW | Three-phase AC380V, 7.5 KW |

| Working Environment | Temperature 0- 40°C Relative humidity<80% | ||

| Degree of Protection | IP54 | ||

| Dimensions(L*W*H ) | 786×690×613(mm) | 980×838×780(mm) | 1170×680×1030(mm) |

| The overall weight of the device | 200kg | 350kg | 600kg |

Choose the pump tube according to the characteristics of different materials; the lifespan of a pump tube decreases as the speed increases; the pump tubes made of three different materials have the same lifespan.

Natural Rubber (NR): Commonly used due to its smooth interior and excellent wear resistance, making it suitable for transferring mildly corrosive and slurry-like materials;

Nitrile Butadiene Rubber (NBR): Made via the emulsion polymerization of butadiene and acrylonitrile, this rubber exhibits strong resistance to oils, alkalis, and detergents;

Ethylene Propylene Diene Monomer (EPDM): This material is a copolymer of ethylene, propylene, and a small quantity of non-conjugated dienes. It has outstanding chemical corrosion resistance, making it particularly resistant to substances like ethanol and strong acids.

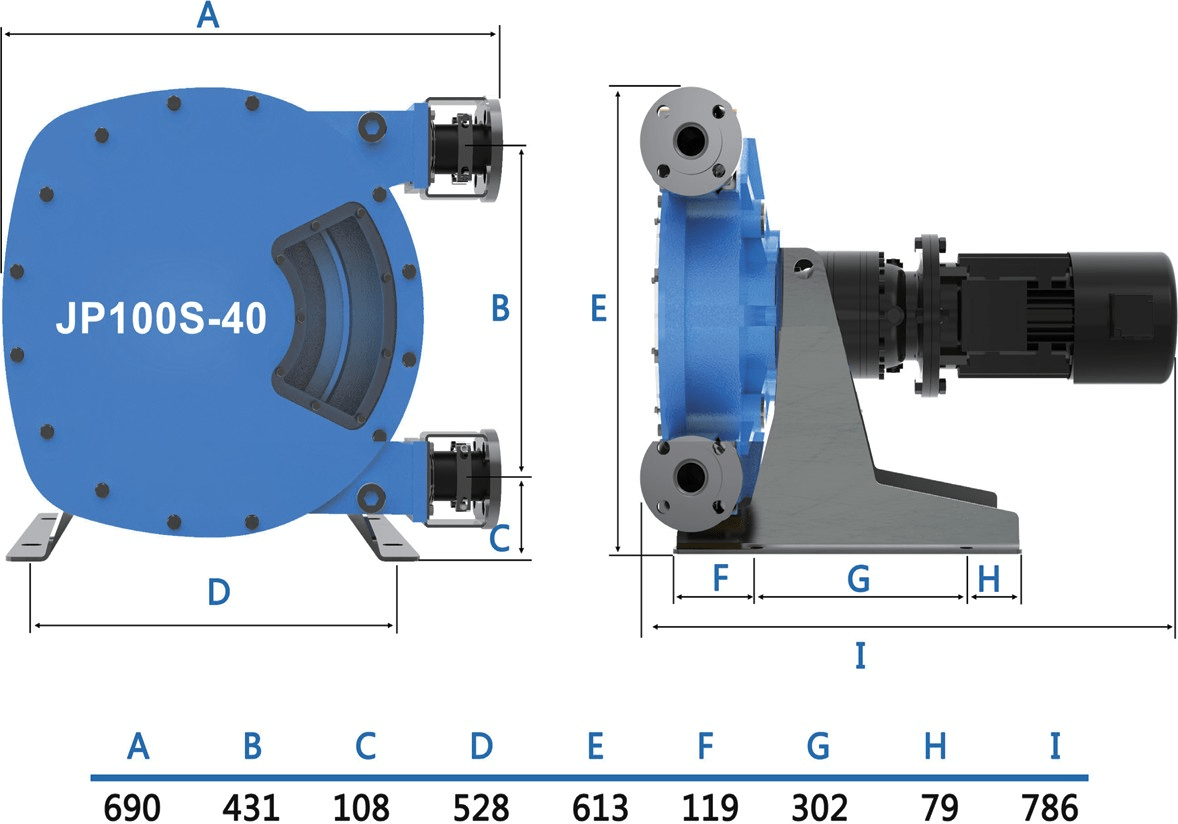

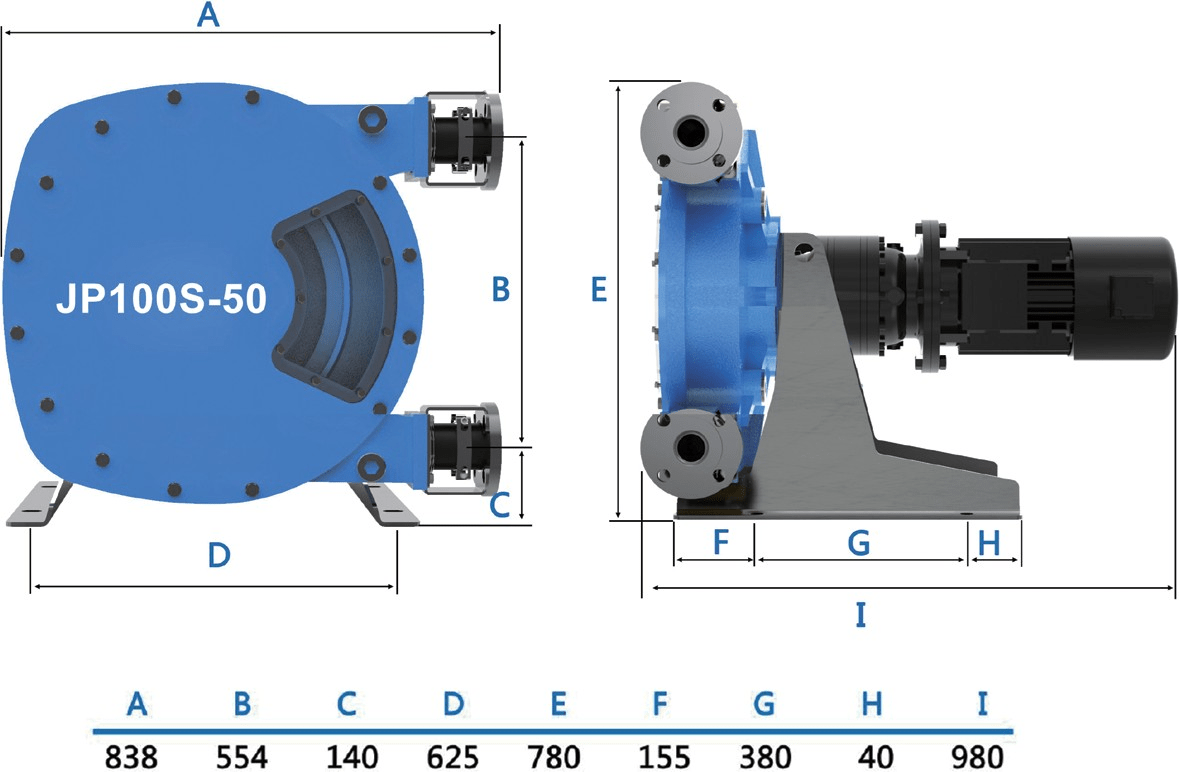

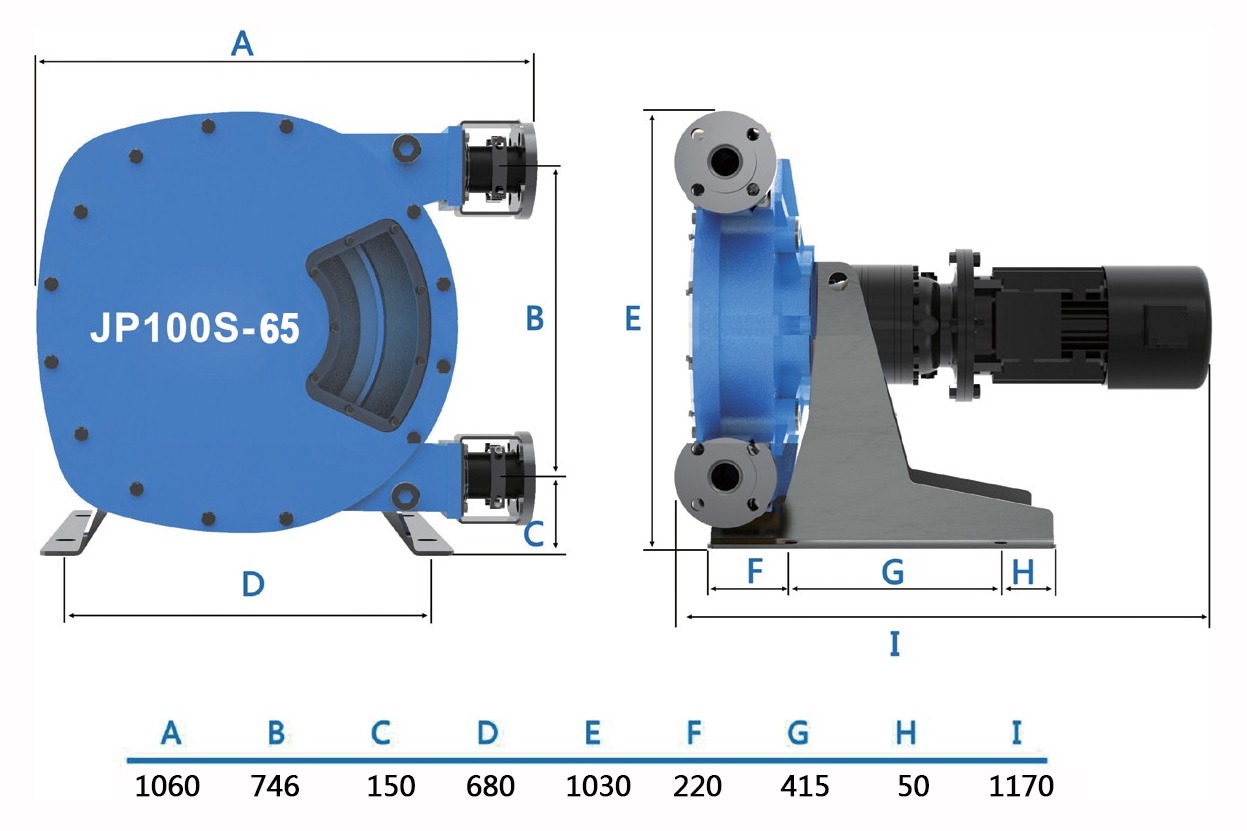

Dimensions(mm)

Dimensions of JP100S-40

Dimensions of JP100S-50

Dimensions of JP100S-65

Applications

• Food industry

• Mining sector

• Chemical industry

• Textile printing and dyeing industry

• Animal feed

• Beer, wine brewing, beverages

• Sewage and Industrial wastewater treatment

• Cosmetics industry

• Fishery

• Recycling