Introduction

•The product series includes three models: B150K1DW10-2, B150K2DW10-2, and B150K3DW10-2;

•The control method is analog speed regulation (4-20mA/0-5V/0-10V selectable);

•External level signal control start/stop/direction function;

•The product is small in size, compact in structure, and aesthetically pleasing in appearance;

•Selected materials are of high quality, sanitary and non-toxic, with high strength, good toughness, and excellent chemical corrosion resistance;

•The pump head uses a spring-pressurized hose fixing structure, which can provide a longer hose life and high-precision flow rate;

•By adjusting the pressure-tube device, the appropriate pressure can be obtained;

•Tube installation is convenient and quick, and it can adapt to various specifications of tubes to meet more application needs;

•This is suitable for low-flow applications and can be used in various instruments and equipment for ODM matching.

Pump Parameters

Motor Types: 42 stepper motor

Power Supply Voltage: DC12-24V

Wattage: <20W

Speed Range: ≤150rpm

Control Mode: Analog signals (4-20mA/0-5V/0-10V)

Start-Stop Method: External Level Signal Control (DC5-24V)

Direction Switch Method: External Level Signal Control (DC5-24V)

Channel Number: 2

Roller Number: 4

Running Direction: Clockwise/Counterclockwise rotation

Adaptable Tube Wall Thickness: 0.85mm

Adaptable Tube ID: 1.52mm/2.06mm

Tube Material: Pharmed

Tube Installation Method: Connector Specifications

Tube-Pressing Type: Spring adjustable

Pump Head Pressure Block Material: PVDF

Material of the Pump Head End Cover: PET

Pump Head Roller Material: PVDF

Pump Head Life: ≥1000h

Noise: ≤60dB (testing environment noise ≤40dB, horizontal distance between test product and noise meter is 1 meter)

Driver Weight: 553g

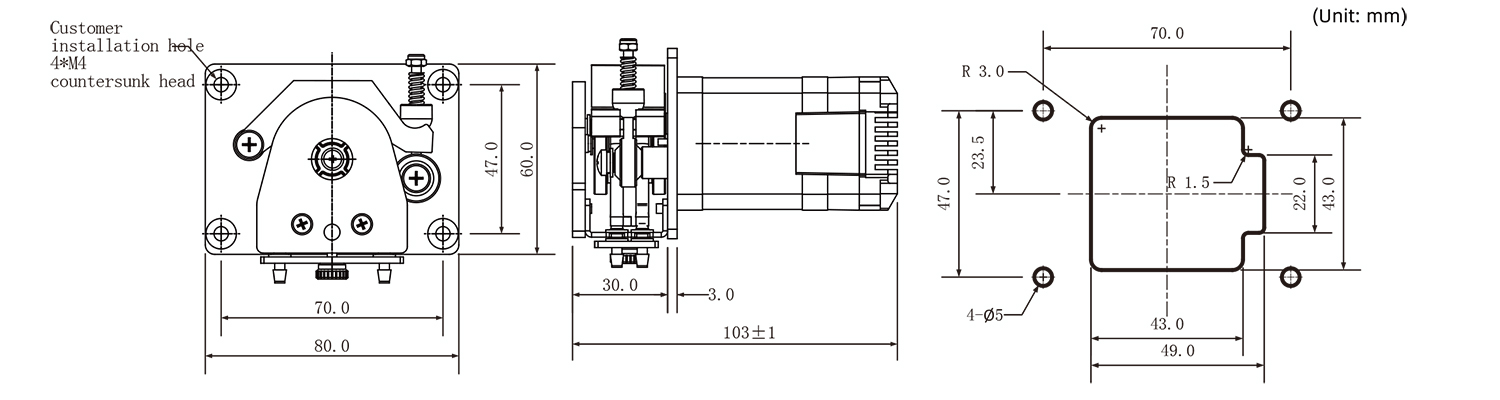

Dimensions: 103*80*60(mm)

Working Environment: Temperature 0- 40°C, , Relative humidity< 85% RH

Storage Environment: In a clean and well-ventilated environment with ambient temperatures ranging from -40 to +50°C, and relative humidity not exceeding 95%, the air must not contain corrosive, flammable gases, oil mist, or dust.

Tube Model and Flow Reference Table

| Tube | Tube No. | Flow Rate(mL/min) | ||||||

| 1rpm | 20rpm | 40rpm | 60rpm | 80rpm | 100rpm (max speed at continuous working) |

150rpm (max running at Intermittent working) |

||

| Pharmed | 1.52*0.85 | 0.1 | 2 | 4 | 6 | 8 | 10 | 15 |

| 2.06*0.85 | 0.15 | 3 | 6 | 9 | 12 | 15 | 22.5 | |

•It is recommended to operate intermittently for speeds above 100rpm. An example of an intermittent operation mode is: run for 3 seconds, stop for 2 seconds,

and repeat the cycle.

•The above flow data were all tested using a Lead Fluid silicone tube to pump pure water under laboratory conditions with normal temperature and

pressure. This data is for reference only.

•Due to pressure in actual use , temperature, medium characteristics, tube material and other specific factors, the specific situation needs to consult

our engineers.

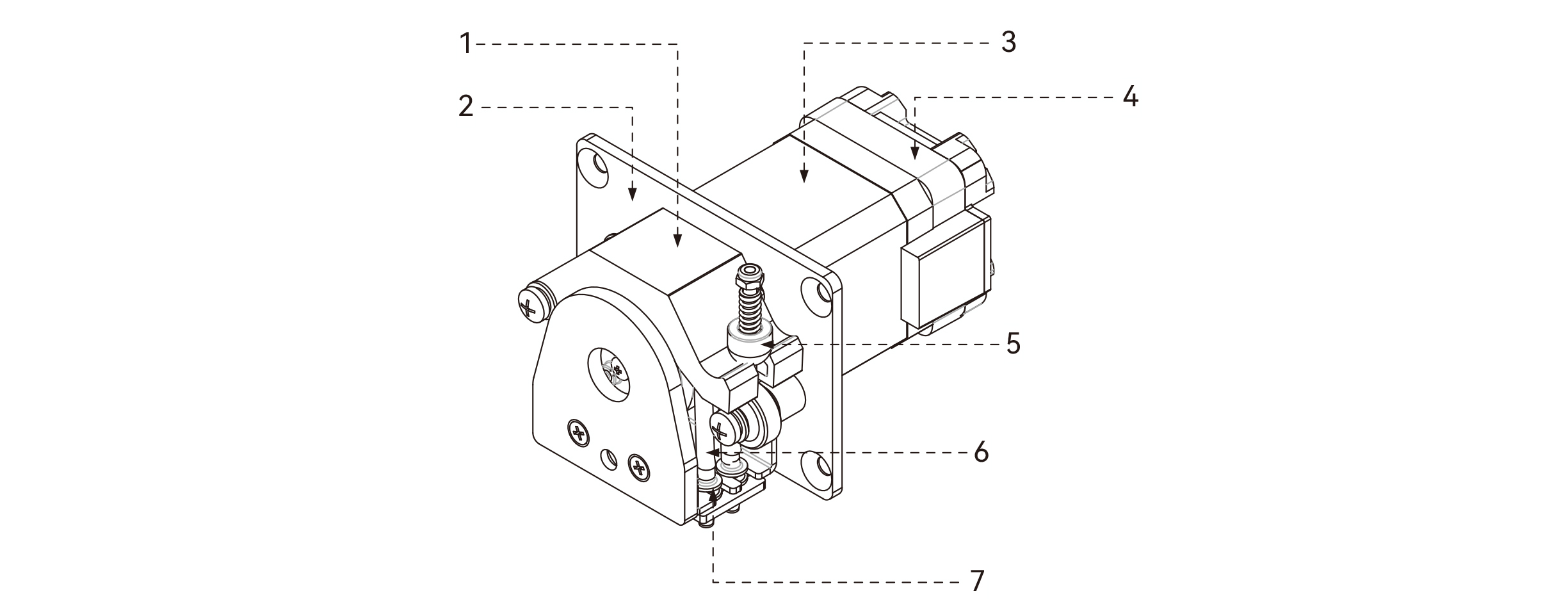

Product Structure

Component name and function:

1.Pump head pressure block: Squeezing the tube with rollers.

2.Mounting Plate: Connects the motor to the pump head bracket and can also be used to install the product onto other equipment;

3.Motor: Drives the pump head;

4.Drive and Control Unit: Provides power, sets operating modes;

5.Commutation screw: Matched with the pump head pressure block;

6.Tube: Transmission of liquid;

7.Tube connector: Securing and connecting tubes.

Usage Method

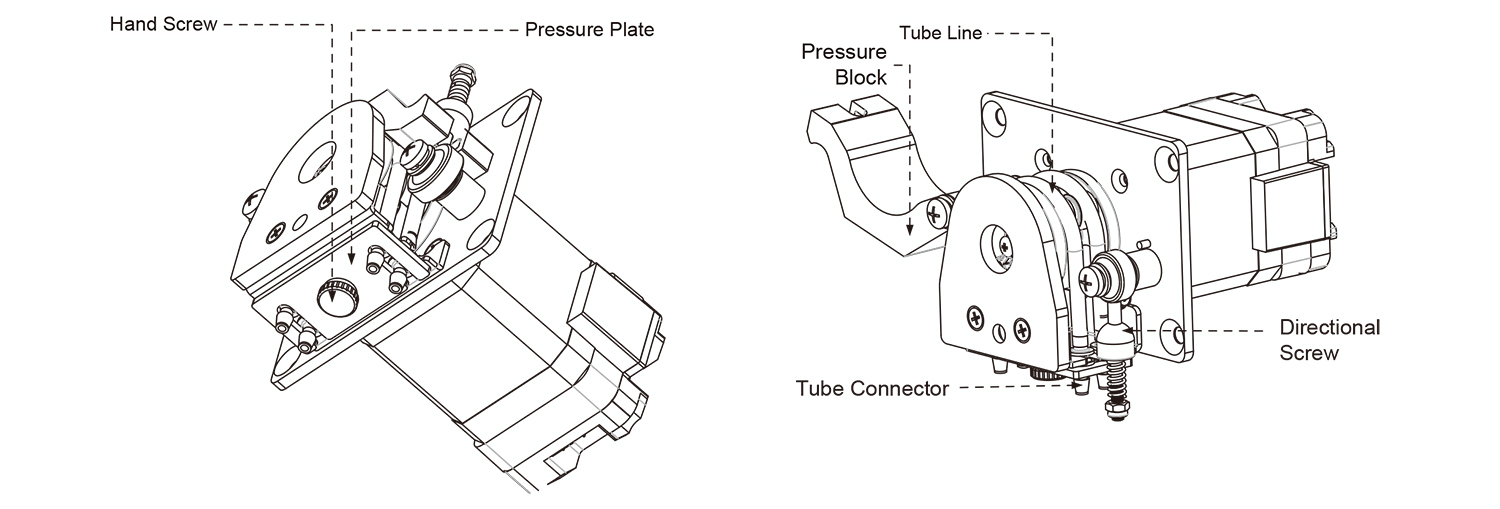

Tube Disassembly

• Step 1: Turn the hand screw counterclockwise to unscrew it, then remove the pressure plate.

• Step 2: First, turn the directional screw down, then lift the pressure block upwards and remove the tube-line and the tube connectors.

Tube Installation

The installation method is the opposite of the disassembly steps mentioned above.