On the path to excellence, Lead Fluid is never content with the status quo. This time, Lead Fluid has deeply listened to user feedback and has made further upgrades to the G3030-1S industrial micro-syringe pump. Whether it’s extending the device’s lifespan or enhancing ease of use, Lead Fluid strives to make each of your uses smoother and to deliver a more reliable fluid handling experience!

1.Significant Durability Improvement with Valve Life Over One Million Cycles

In fluid handling, equipment durability directly impacts production efficiency and costs. Lead Fluid understands this well and has focused on enhancing product durability.

After rigorous testing and validation, the G3030-1S now features valves with a lifespan exceeding one million cycles. This ensures long-term stable operation, significantly reduces replacement frequency and maintenance costs, and provides users with a more economical option while ensuring continuous and efficient production processes.

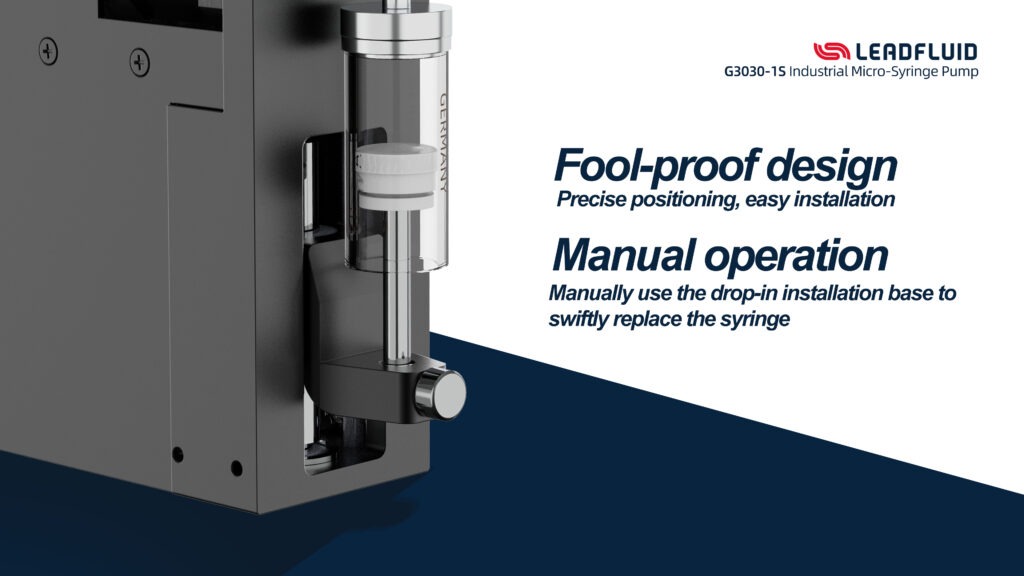

2.Easy Installation and Efficient Operation

Lead Fluid understands the importance of time for users, especially in fast-paced production and research environments. Therefore, ease of use has been a key focus in product design.

The G3030-1S features a manual pull-down mounting seat that makes syringe replacement quick and easy. Additionally, the rotary valve’s foolproof design effectively reduces the risk of user error, making the device more intuitive to use and enhancing overall work efficiency.

3.High-Precision Feedback System

The G3030-1S is equipped with a high-precision feedback system that maintains exceptional detection sensitivity and operational stability, even in complex and variable working environments. This ensures high accuracy and consistency in fluid handling.

4. Flexible Configurations, Perfect Compatibility

The original instruction set is perfectly compatible with mainstream products in the market, and supports independent use or cascading of 15 pumps. It is applied in instrument supporting systems such as environmental detection instruments, gold spraying and film scraping instruments, and pipetting workstations, meeting the high-performance fluid processing needs in industrial and scientific research scenarios.

More Product Highlights

Intelligent limit protection

Accurately monitor the operating range of the pump, prevent over limit operations, and provide safety assurance for the equipment.

High performance components

Durable screw and precision motor enhance equipment lifespan, precision, and efficiency, while also allowing for low-noise operation.

Convenient settings and quick upgrades

Dial code settings enable quick switching and offline operation of valves, supporting online upgrades.

Stable connection

Gold plating process interface ensures stable and reliable signal transmission.

Craftsmanship Pursuit

In the development process of G3030-1S, a seemingly simple manual pull-down operation was hidden behind the unremitting efforts and wisdom of the Lead Fluid engineering team. Faced with the numerous challenges of the first generation design, they constantly tried and broke through, from motor selection to guide column technology, to material innovation. In the end, they optimized this operation from the initial bulky and difficult to push to the current easy and smooth. Not only does it improve the convenience of product operation, but it also demonstrates the deep understanding and respect of Lead Fluid engineers for user experience.

Every improvement is Lead Fluid commitment to quality and deep understanding of user needs. G3030-1S is ready to play a key role in your workflow, helping you improve work efficiency and reduce operating costs.