Features

1. High-Precision Feedback System

Even in complex environments, this system maintains excellent detection sensitivity and operational stability, ensuring high precision and

consistency in fluid handling.

2. Versatile and Durable

Equipped with intelligent limit protection, it accurately monitors the pump’s operating range to prevent over-limit operations, providing

comprehensive safety assurance.

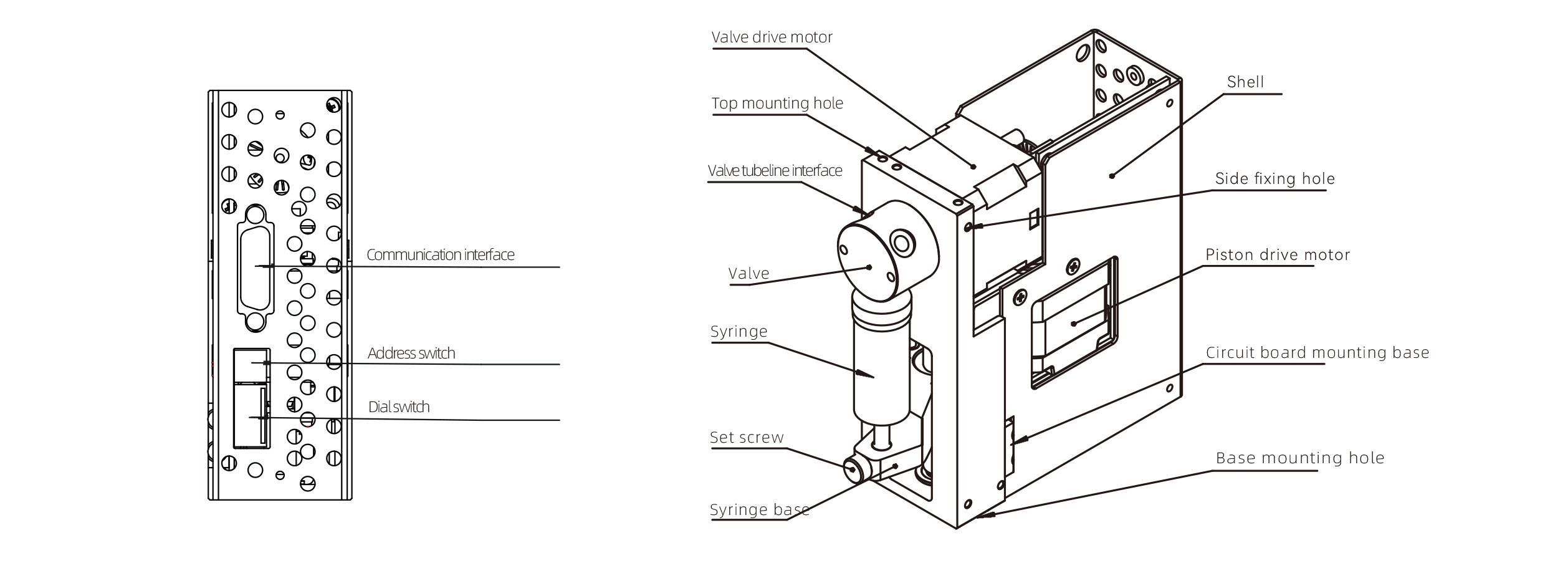

3. Easy Installation

The manual pull-down installation base allows for quick syringe replacement. Its foolproof design simplifies installation and improves

operational efficiency.

4. Convenient Setup and Quick Upgrade

DIP switch settings enable fast valve switching and offline operation, making the process smoother. It also supports online upgrades, enhancing

flexibility and adaptability.

5. Command Set Compatibility

The unique command set is perfectly compatible with mainstream market products, offering broader application support.

6. Stable Connection

The gold-plated interface ensures a stable and reliable connection.

7. Intelligent Limit Protection

This system precisely monitors the pump’s operating range to prevent over-limit operations, providing safety assurance.

8. High-Performance Components

Durable lead screws and powerful motors increase the equipment’s lifespan, precision, and efficiency, while low-noise operation ensures a

comfortable working experience.

9. Flexible Configuration

It can be used independently or in a cascade with up to 15 pumps, adapting to various fluid handling needs.

Parameters

Linear speed: 0.005mm/s~25mm/s

Running time: 1.2s~100min

Flow accuracy: ≤±1%

Pusher advance per microstep: 0.01mm/step

Channel: 1

Power supply: DC24V±10%,electric current≤1.5A

Syringe: 50uL,100uL,250uL,500uL,1mL,2.5mL,5mL

Rated stroke: 30mm (3000 step(standard/24000 step(microstep))

Valve fitting: 1/4~28UNF internal thread

Piston driving force: Stepper motor drive, orthogonal encoding detection position

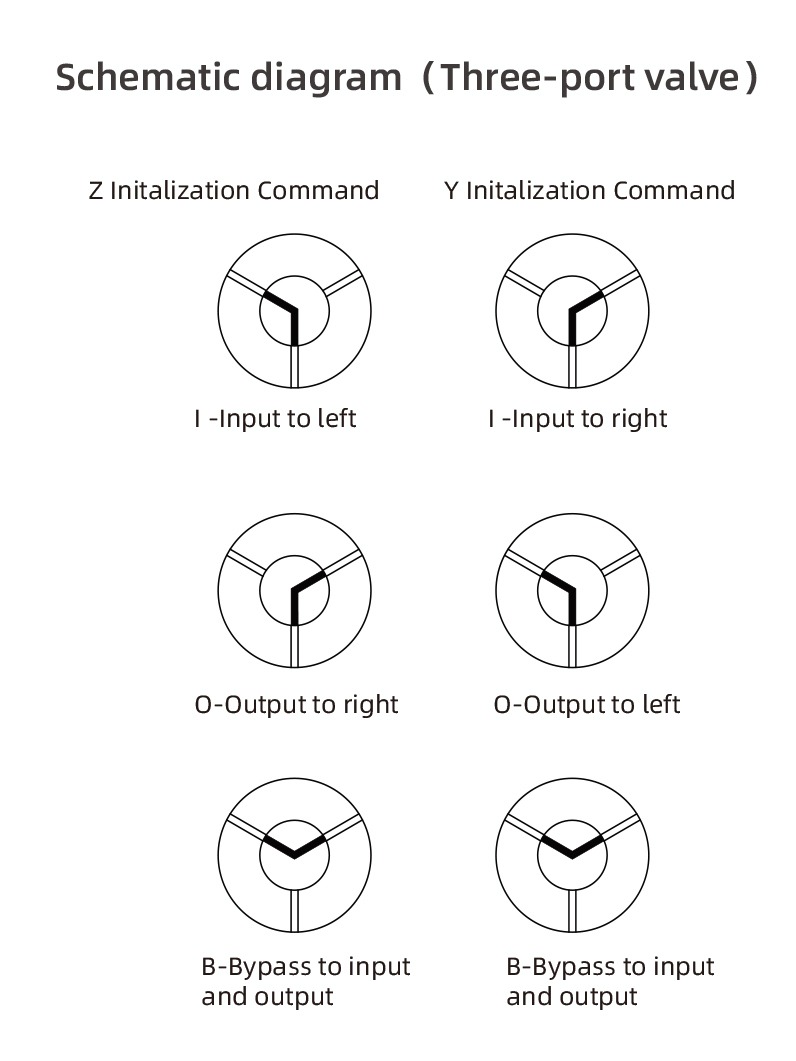

Applicable valve: 3-way valve,4-way valve,6-way valve,9-way valve

Valve displacement time: ≤280ms

Materials in contact with fluids: Borosilicate glass, Kel~F and Teflon

Communication interface: RS232/RS485,9600/38400 baud rate optional

Parameter setting: 7 digit dial switch

Signal input: 2 gates TTL Level signal input

Signal output: 3 gates TTL level signal outpump

Shell material: Aluminum alloy

Programming function: Ramp, cut-off speed, gap compensation, infuse speed, circulation, real-time termination of movement and delay, error detection, valve rotation selection, storage of 15 groups of operating modes

Working environment: Temperature 15℃~40℃,relative humidity<80%

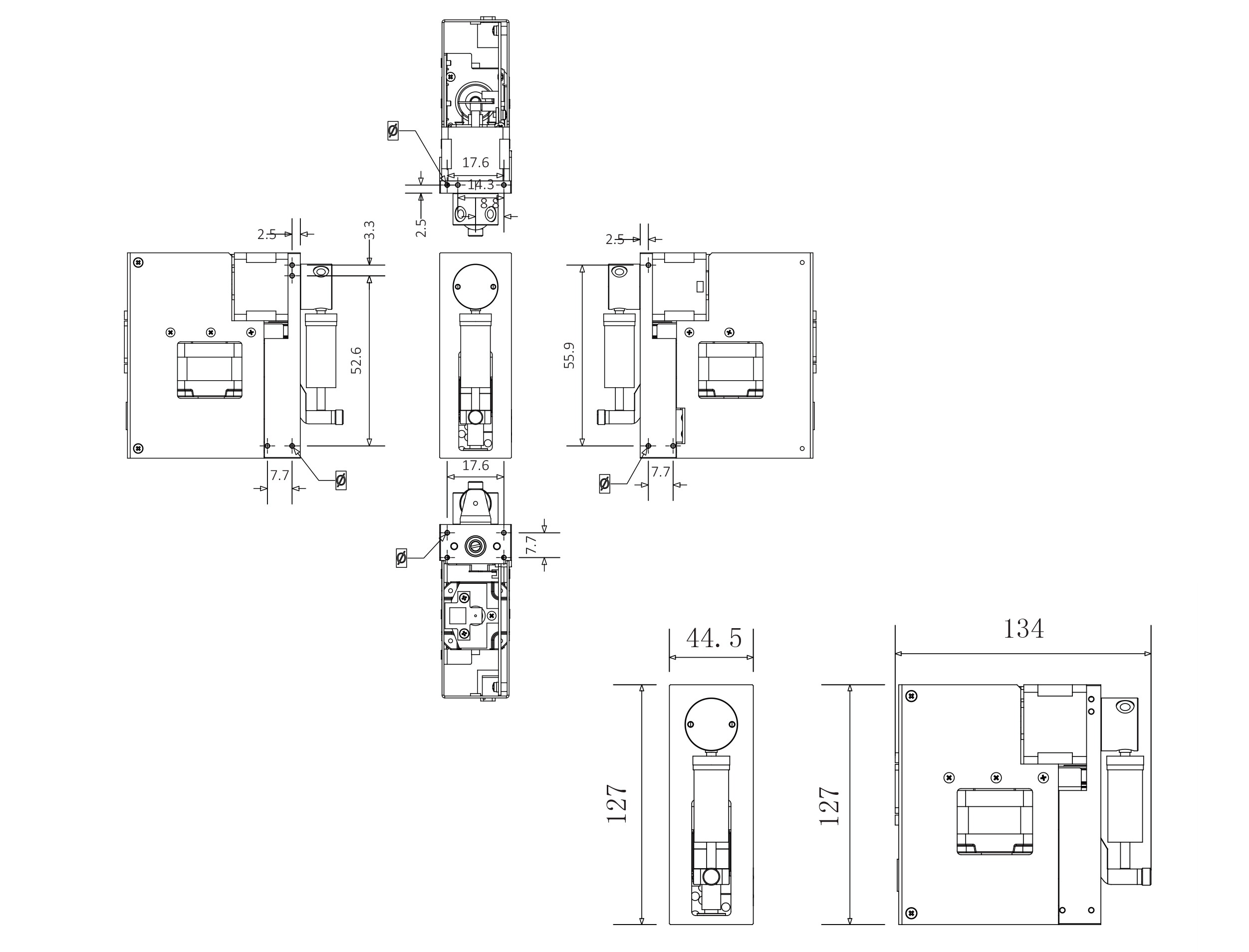

Dimension(L×W×H): 134×44.5×127(mm)

Weight: 1.23kg

Above flow parameters are obtained by transfer pure water under normal temperature and pressure, in actually using it is effected by specific factors such as pressure, medium etc. Above for reference only.

Connector and Tubeline

Thread inverted taper joint

| Specification | 1/4-28UNF |

| Material | PTFE |

Transmission line

| Specification | 0.5×1.6mm 1.0×1.6mm 1.6×3.2mm |

| Material | PTFE |

Syringe Flow Rate Patameters

|

Syringe Size

|

Min Flow Rate(mL/min)

|

Max Flow Rate(mL/min)

|

|

50μl

|

0.0005

|

2.5

|

|

100μl

|

0.0010

|

5

|

|

250μl

|

0.0025

|

12.5

|

|

500μl

|

0.005

|

25

|

|

1ml

|

0.010

|

50

|

|

2.5ml

|

0.025

|

125

|

|

5ml

|

0.05

|

250

|

Above flow parameters are obtained by using silicone tube to transfer pure water under normal temperature and pressure, in actually it is effected by specific factors such as pressure, medium, etc. Above for reference only.