How did the Peristaltic Pump DS600 Enter Pharmaceutical Workshops and Unlock A New paradigm of “precision, efficiency, and compliance” in filling?

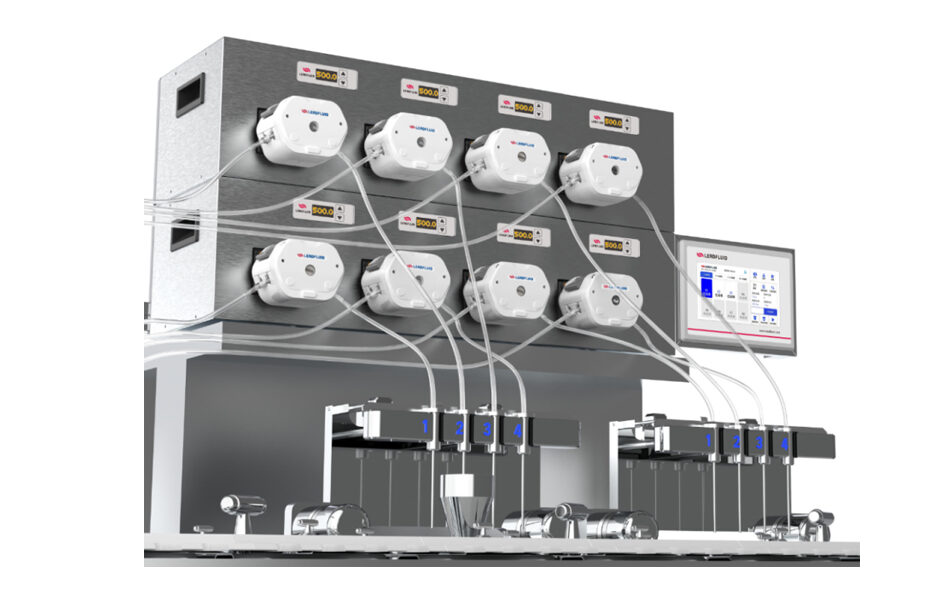

Site Overview At a pharmaceutical facility in Hainan, the DS600 filling system equipped with DMD15 pump heads is accurately dispensing 5mL of medicinal solution into vials. The process demonstrates tight synchronization between equipment and production line—precise dosing, orderly vial movement, and crystal-clear solutions—showcasing a modern filling line that balances accuracy, efficiency, and compliance. In the pharmaceutical industry, behind every filling line a strict requirement for dosage control precision, comprehensive monitoring of the entire production process, and a continuous test of the equipment’s ability to operate reliably over the long term!… Read More »How did the Peristaltic Pump DS600 Enter Pharmaceutical Workshops and Unlock A New paradigm of “precision, efficiency, and compliance” in filling?