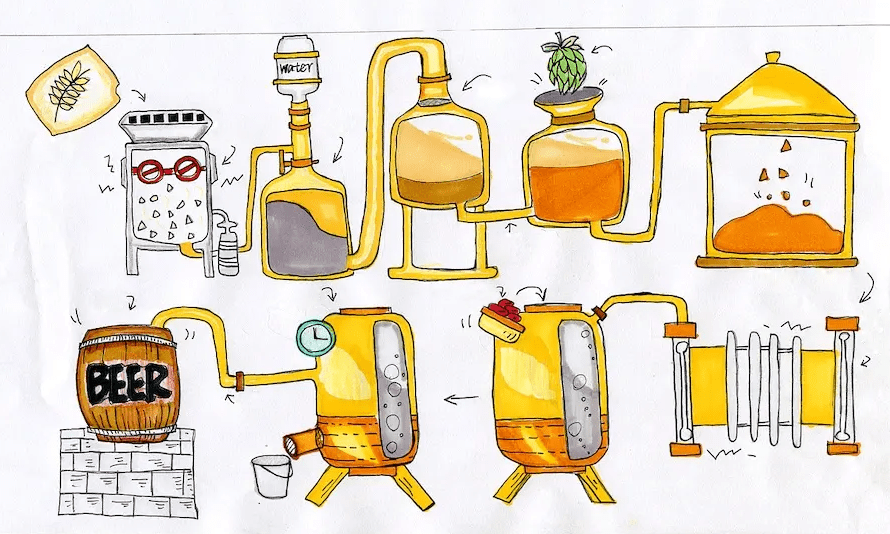

Beer may seem simple, but in fact, the production process is complex and lengthy, involving multiple links such as raw material processing, saccharification, fermentation, maturation, filtration, and filling. The main component of beer is water, so the water treatment issues involved in various stages of production are particularly important. The Lead Fluid peristaltic pump is widely used in the brewing process of beer due to its precise hygiene, safety and reliability, customizability, compatibility, easy operation, and integration, as well as its significant advantages in cost-effectiveness and practicality compared to large mechanical equipment.

1.Addition of Yeast

Beer fermentation is an important process that requires the addition of an appropriate amount of yeast in the fermentation tank. Yeast converts the sugar in wort into alcohol and carbon dioxide through fermentation, thereby giving beer its unique taste and taste. The timing and dosage of yeast addition have strict standard requirements. The Lead Fluid BT600L flow intelligent peristaltic pump can achieve precise yeast addition and uniform distribution, ensuring that yeast can fully play its role in the fermentation process. Meanwhile, the excellent sealing performance of the Lead Fluid peristaltic pump can prevent yeast from being contaminated during transportation.

Representative products

Lead Fluid BT600L Intelligent Dispensing Peristaltic Pump

2.Beer Filtration

After beer fermentation is completed, it needs to be filtered to remove residual yeast, protein, and impurities to ensure the quality and taste of the beer. The Lead Fluid WG600S variable speed peristaltic pump can transport beer from the fermentation tank to the filtration equipment. By controlling the flow and pressure, it ensures that the beer will not leak or be damaged. Throughout the pumping process, the pump pipe is the only contact component, and there are no valves or seals required on the pipeline, meeting the hygiene requirements of beer brewing.

Representative products

Lead Fluid WG600S Speed Variable Peristaltic Pump

3.Beer Filling

After beer manufacturing is completed, it needs to be bottled or filled into other containers. The Lead Fluid DS600 series peristaltic pump filling system can provide precise flow control in this process, ensuring the speed and stability of the beer filling process. At the same time, the suction function of the peristaltic pump ensures that there is no dripping or splashing during the entire filling process, ensuring the cleanliness and tidiness of the production line.

Representative products

Lead Fluid DS600 Series Filling System Peristaltic Pump

Lead Fluid has always been paying attention to the development needs of food and beverage manufacturers, and we are well aware of the importance of product quality for a company’s brand and reputation. To this end, Lead Fluid continuously improves the performance and reliability of its products to meet customers’ needs for high-precision, hygienic, low maintenance, high abrasion and shear sensitive materials, and helps more food and beverage manufacturers improve production efficiency and product quality, thus occupying a leading position in market competition.