Feature

Efficient integration, achieving a perfect combination of accuracy, efficiency, and stability

• Compact size and modular design, capable of cascading 16 pumps to create a multi-channel filling system

• High precision stepper motor drive, high torque, maintenance free

• Minimum dispensing volume 1 μL. And the filling accuracy is high

• Can achieve efficient packaging, up to 120 bottles per minute

• Suitable for various liquids, including magnetic beads, glycerol solution, etc

New UI interface, user-friendly design, beautiful and easy to operate

• Information query function, which can conveniently view the operation records of each channel

• Quickly copy parameters to multiple channels

• New calibration algorithm for easier liquid volume calibration

• One click cleaning and one click recycling

• Support video playback assistance

• Support firmware upgrade by USB drive

Data security and intelligent formula management bring information security and easy operation

• Dual protection

• Third level user permission management

• A brand new formula management system that supports operations such as creating, deleting, and naming in both Chinese and English

• Support USB import and export of formulas

Refined structure, efficient improvement of filling efficiency and reduction of losses

• Multi roller positioning and spring type pressure tube structure can effectively improve filling efficiency

• Nano level infusion needle, zero drop

• Low pump tube loss prolongs the service life of the pump tube and delays the attenuation of filling volume

Comfort for using

• High cleanliness tubeline, easy disassembly, conducive to cleaning and sterilization, supporting CIP and SIP

• It can be operated manually or used in conjunction with an automatic production line

Technical Parameters

Filling range: 1μL~3000μL

Accuracy: 10μL±0.15, 50μL±0.15, 100μL±1, 500μL±6, 1000μL±10, 3000μL±18

Channel: 1(Single), up to 16 channels cascade are supported

Filling time: 0.01~999.99S

Interval time: 0.40~3600S

Filling times: 1~10000, 0 means circle

Tubing: ID 0.5~4.8mm

Display: 7 inch HD color touch screen

External control: Start signal (Dry contact ), lack of bottle filling stop signal, feedback signal

Shell material: Aluminum alloy

Maximum pressure: 0.15Mpa

Power supply: AC 100~240V

Power consumption: 36W(single channel), 60W(double channels),85W(three channels),110W(four channels)

Working environment: Temperature 0 ~ 40℃, relative humidity<80%

IP grade: IP31

Controller weight: 1.5kg

Driver weight: 3.2kg

Characteristics Comparison

|

WSP3000 Microliter Peristaltic Pump

|

Traditional Peristaltic Pump

|

|

|

Filling Accuracy

|

When filling 10 μ L ,error less than ± 0.15 μ L; When filling 100 μ L, error less than 1 μ L; Accuracy error less than ± 0.3% | Not suitable for filling less than 100μL, the error of 200μL is less than ±3μL |

|

Filling Efficiency

|

Can reach 120 bottles/minute | The output is less than 40 bottles per minute |

|

Volume Decrease |

Run continuously for 12 hours with less than 1% attenuation,and no calibration is required for a day’s work | The continuous running time is 12 hours, and the attenuation is more than 5%; usually it needs to be calibrated every 2 hours |

|

Tube Life

|

More than 1000 hours when it runs continuously | Between 70 to 100 hours |

|

Characteristics |

Perfect combination of special mechanical structure and tube kits realizes zero hanging liquid | Traditional structure,it’s easy to hang liquid at the tip of the needle |

|

|

WSP3000 Microliter Peristaltic Pump | Ceramic Plunger Pump |

|

Cleanliness |

No blind area, no accumulation of liquid, materials only contact with clean tube, no pollution |

Blind area, liquid accumulation, contact between material and pump head cavity, and insufficient cleaning |

|

Usability |

Filling different materials requires only replacement of tubes to avoid cross contamination, simple maintenance, and low cost |

A pump can only fill one material, and the maintenance is complex |

|

Universal |

The liquid may contain magnetic beads and other particles |

The liquid must be clean and free of impurities |

|

Filling Range |

1μL~3000μL(single channel) |

0.3~100mL,0.5~500mL(single channel) |

|

Liquid drop |

No dropping |

Easily Dropping |

|

Fallen objects |

Low extrusion strength, no mechanical friction, and smooth inner wall of the cavity without shedding objects |

Mechanical continuous friction, easy detachment of particles from the cavity |

WSP3000 Filling Accuracy and Efficiency

|

Tube

|

Accuracy(μL)

|

Filling Range

|

Accuracy Error

|

Filling Time

|

8 Hours Attenuation Rate

|

Recommended RPM

|

|

120#

|

±0.1μL |

1μL,5μL,10μL,20μL

|

<±10%,<±2%,<±1%,<±0.5%

|

0.01-0.02, 0.04-0.12,

0.09-0.23, 0.18-0.46

|

<±1%, <±1%,

<±1%,<±1% |

>150,>150, >150,>150 |

|

13#

|

±0.2μL

|

20μL,50μL

|

<±1%,<±0.4%

|

0.1-0.24, 0.25-0.6

|

<±1%, <±1%

|

>150,>150

|

|

121#

|

±0.5μL

|

50μL,100μL

|

<±1%,<±0.5%

|

0.08-0.2, 0.16-0.4

|

<±1%, <±1%

|

>150,>150

|

|

14#

|

±1μL

|

100μL,200μL

|

<±1%,<±0.5%

|

0.13-0.3, 0.26-0.6

|

<±1%, <±1%

|

>150,>150

|

|

19#

|

±2μL

|

200μL,300μL,500μL

|

<±1%,<±0.6%,<±0.4%

|

0.1-,0.25, 0.15-0.35,0.25-0.6

|

<±1%, <±1%,

<±1% |

>150,>150,>150

|

|

16#

|

±4μL

|

300μL,500μL

|

<±1.6%,<±0.8%

|

0.1-0.22, 0.16-0.35

|

<±1%, <±1%

|

>150,>150

|

|

25#

|

±8μL

|

800μL

|

<±1%

|

0.11-0.23

|

<±1%

|

>150

|

|

17#

|

±16μL

|

2mL,3mL

|

<±0.8%,<±0.5%

|

0.3-13-0.26, 0.5-1

|

<±1%,<±1%

|

>150,>150

|

1.Test condition for the above data:At normal temperature and pressure, with the level of water unchanged, silicone hose is used for transmission. The inlet end is 1 meter and the outlet end is 1 meter. All weighing data are measured by Sartorius high-precision balance with accuracy of one hundred thousandth.

2.The error value and accuracy data are based on 50 sets of continuous measurements, and this data does not include the influence of the last drop.

3.8-hour decay rate:Under the condition of 60 bottles/minute, after the equipment is installed and debugged, run for 3 hours first, then record 10 sets of filling data every 12 hours, run continuously for 5 days and take the maximum value.

4.During the filling process, the precipitation of dissolved gases in the liquid will produce bubbles, which will have a great impacton the accuracy of filling below 1000μl. Pay attention to bubble removal during use.

5.The final explanation right of above information belongs to Lead Fluid, please consult Lead Fluid engineers for more details.

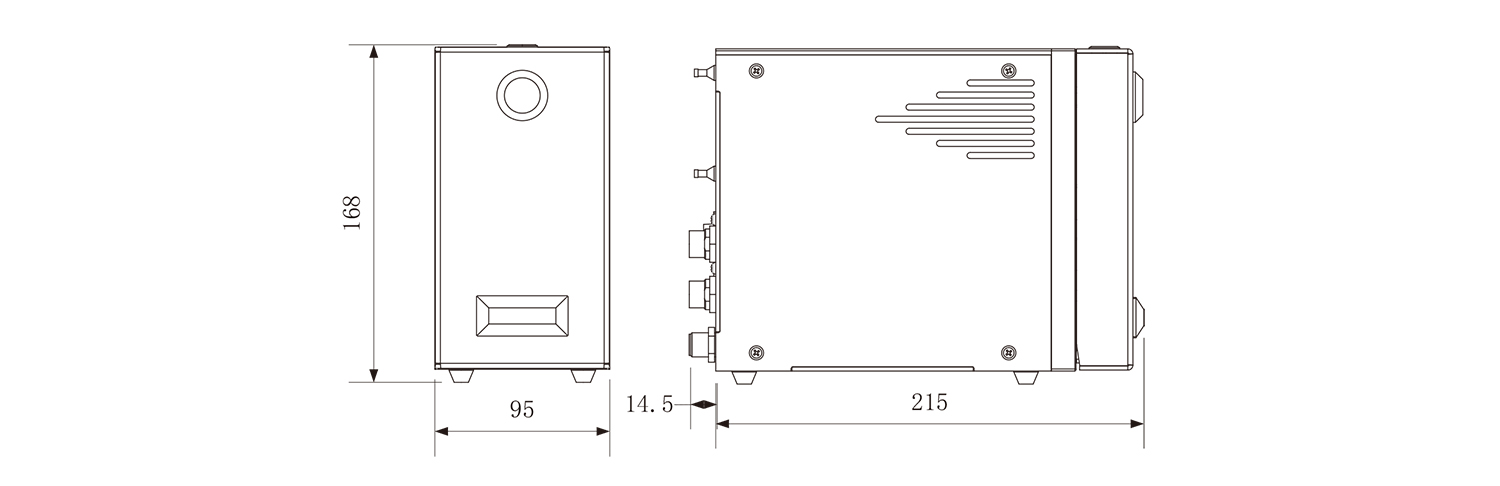

Pump Dimension(unit:mm)

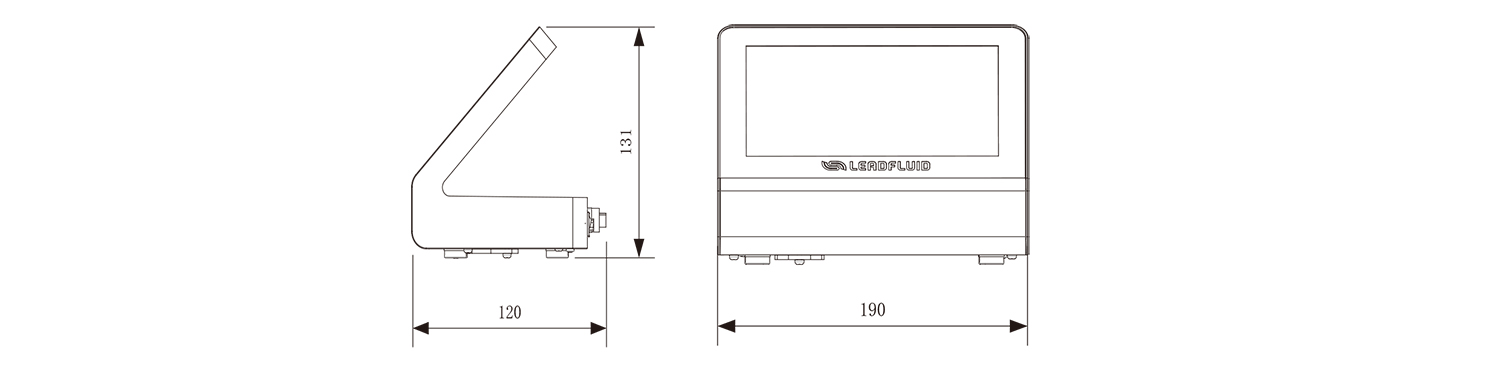

Controller Dimension(unit:mm)