Introduction

• Small size, compact structure, beautiful appearance.

• High-quality material selection, sanitary and non-toxic, high strength, good flexibility,

and excellent resistance to chemical corrosion.

• The pump head utilizes a spring-loaded tube mounting structure that provides long tube life

and high precision flow, the proper pressure can be obtained by adjusting the pressure tube unit.

• Adjusting the pressure tube device allows obtaining the appropriate pressure.

• The tube is easy and quick to install, and it can be adapted to various specifications, meeting a wide range of application requirements.

• Suitable for low-flow applications, it can be used as an ODM matching accessory in various instruments and equipment.

Parameters

Motor Type: 42 stepper motor

Drive and Control Method: Customer provided

Speed Range: ≤150rpm

Flow Range: ≤63mL/min (single channel flow rate, flow rate is proportional to the number of channels)

Channel Number: 1 / 2 / 3 channel

Number of Rollers: 4 rollers

Rotation Direction: Clockwise/Counterclockwise rotation

Lift Head: 8 m

Suitable Tube: Wall thickness: 0.85mm, ID: 0.76mm, 1.3mm, 1.52mm, 2.79mm, 3.2mm

Material of Tube: Wall thickness: 0.92mm, ID: 1mm, 2mm, 2.4mm, 3mm

Method of Tube Installation: Silicone, Pharmed

Pressure Tube Type: Tube Connectors

Pump Head Pressure Block Material: Spring adjustable

Pump Head Cover Material: PVDF

Pump Head Roller Material: PET

Pump Head Life: >1000h

Noise: ≤60dB (test environment noise ≤40dB, test product and noise meter horizontal distance of 1 meter)

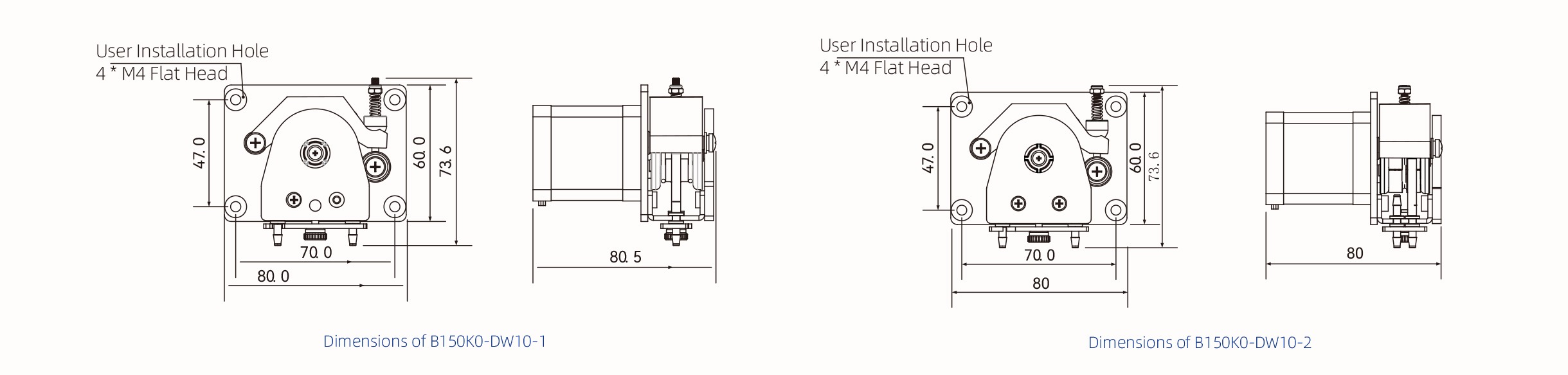

Weight: 500g/520g/540g (Without tube)

Dimensions: (L×W×H) 80.5*80*60 (mm), 80*80*60 (mm), 91*80*60(mm)

Working Environment: Temperature 0- 40°C, relative humidity<80% RH

Storage Environment: Ambient temperature of -40 ~ +50 °C, relative humidity of not more than 95% of the clean and well-

ventilated environment, the air shall not contain corrosive, flammable gases, oil mist, dust.

Product Structure & Usage Method

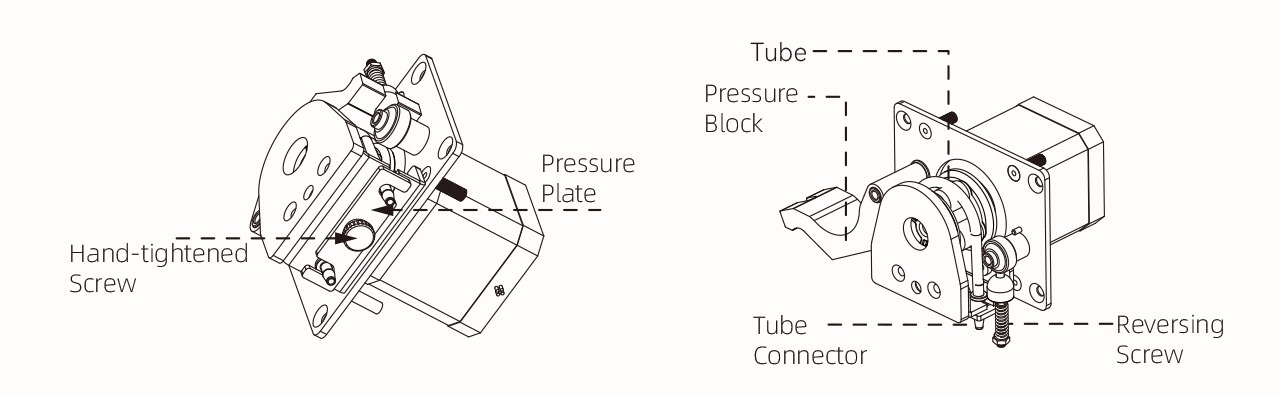

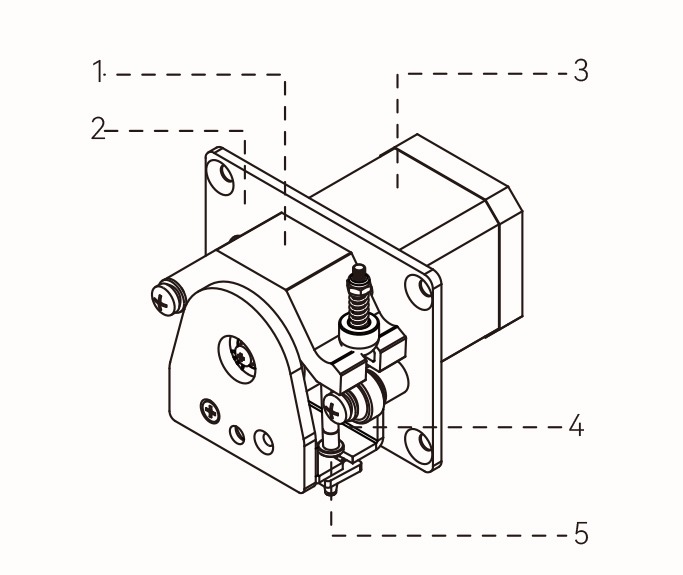

Product Structure

Component Name and Function

1.Pump Head Pressure Block: Squeezes the tube along with the roller assembly.

2.Mounting Plate: Connects the motor to the pump head bracket and

allows the product to be installed on other devices.

3.Motor: Provides power.

4.Tube: Made of silicone or pharmed material.

5.Tube Connector: Secures the tube in place.

Usage Method

Step 2: Remove the reversing screw, then lift the pressure block upward,

and take out the tube and tube connector.

Disassembling the Tube

Step 1: Unscrew the hand-tightened screw counterclockwise, then rotate

the pressure plate clockwise while applying downward force to remove it.

Install Tube

Reverse the order of disassembly.

Motor Parameters

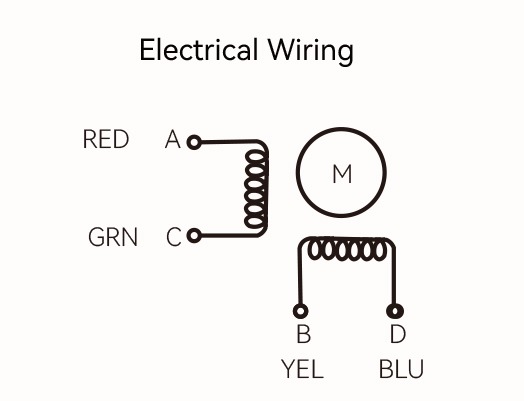

Phase Number: 2

Step Angle: 1.8°

Rated Voltage: 6.3V

Phase Current: 0.7A

Phase Resistance: 8.9Ω±10%

Phase Inductance: 19.2mH±20%

Holding Torque: 5.4kg*cm

Electrical Stress: AC500V/1min/5mA Max

Insulation Grade: B (130°C). Temperature rise 80K Max

Ambient Temperature: -10°C-50°C

Lead Wire Specifications: UL1007/AWG26/300±10mm