Did you know? On average, 2.25 billion cups of coffee are consumed worldwide every day! Lined up, the cups could encircle the Earth 7.5 times!

As of today,the charm of coffee is no longer limited to the essential need of office workers and exam-takers but has become a “source of joy” for many young people to punch in and experience, or even delve deeply into research.

Coffee Essential Oil

Coffee essential oil, a highly concentrated and valuable aromatic substance extracted from coffee beans, is an important component of coffee flavor. Some internationally renowned coffee brands add a small amount of coffee essential oil to their products to enhance the aroma and make the taste richer and more complex.

The addition of coffee essential oil is by no means casual. Its dosage is carefully calculated and meticulously blended; too much feels overpowering, too little feels bland. Only with precise control can the perfect taste be achieved.

Lead Fluid Peristaltic Pumps Applied in Clean and Efficient Filling of Coffee Essential Oil

In the current coffee industry that values both quality and efficiency, how to achieve efficient, clean production while ensuring flavor has become a focal point for food machinery development companies. Recently, a food machinery development company faced challenges in selecting equipment for filling coffee essential oil while customizing a coffee filling machine for its overseas client. The company set stringent requirements for the cleanliness, accuracy, and efficiency of the equipment. The Lead Fluid team, leveraging their extensive expertise in the field of micro-flow liquid control for food, responded quickly. After in-depth technical analysis and multiple discussions with the client, the Leifu team recommended the HSP3000 milliliter peristaltic pump for filling coffee essential oil.

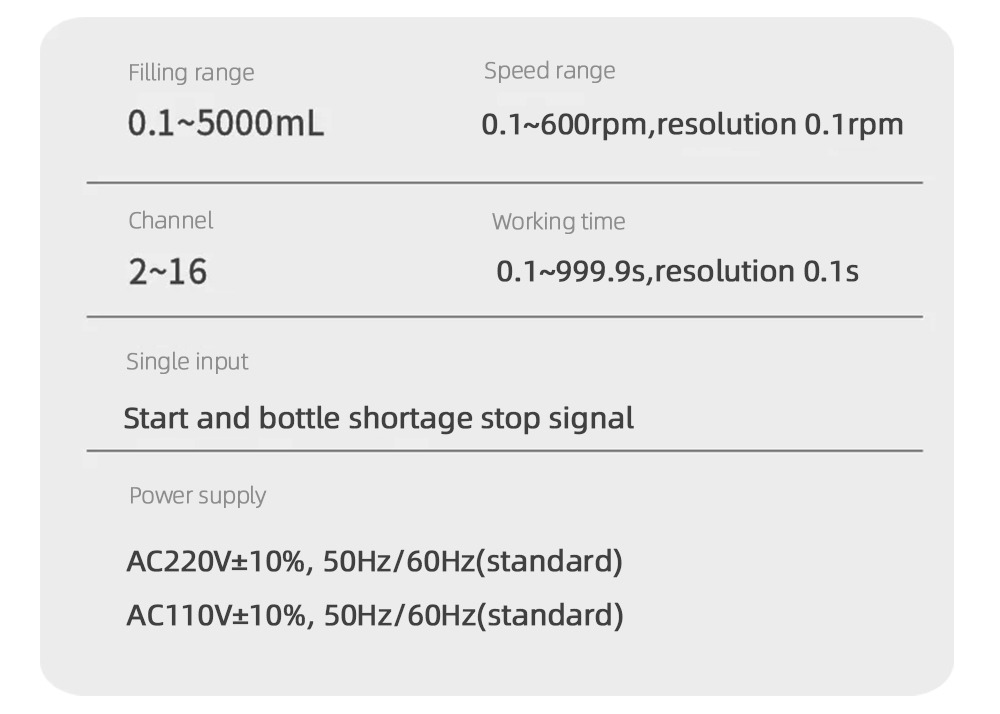

Technical Parameter

Filling range: 25μL~3000μL

Accuracy: ±2%

Channel: 1(single), up to 16 channels cascade are supported

Filling time: 0.01~999.99S

Interval time: 0.40~3600S

Filling times: 1~10000, “0”Infinite cycle

Tubing: ID 0.5~4.8mm

Display: 7 inch HD color touch screen

External control: Pneumatic signal input (dry contact), distribution signal output (if open leakage is pulled up)

House material: Aluminum alloy

Maximum pressure: 0.15Mpa

Power supply: AC 100~240V, 50-60Hz

Power consumption: Single channel 35W

Working environment: Temperature 0 ~ 40℃, relative humidity<80%

IP grade: Temperature 0 ~ 40℃, relative humidity<80%

Controller weight: 1.5kg

Driver weight: 3.2kg

Feature

01 Micro-graded filling

The HSP3000 covers a filling volume from 25μL to 3000μL, meeting the need for micro-quantity coffee essential oil filling in small cans of coffee.

02 High efficiency

The HSP3000 supports up to 16 pumps cascading. A single pump head’s filling efficiency can reach up to 120 bottles/min, which is three times the efficiency of ordinary peristaltic pumps. This high filling speed significantly enhances the overall production capability of the production line, shortens the production cycle, and meets the demand for mass production.

03 High precision

Through special mechanical structure design, the HSP3000 achieves a perfect combination of precision, efficiency, and stability. The filling accuracy can reach ±2%, ensuring the consistency of each can of coffee flavor.

04 No contamination

Avoiding contamination during the filling process is key to ensuring product quality and safety. When the HSP3000 operates, the liquid flows only within the pump tube and does not contact the mechanical parts of the pump, greatly reducing the risk of contamination. Additionally, the pump tube is easy to disassemble, convenient for cleaning and sterilization, supporting CIP and SIP, further ensuring the hygiene standards of the production process, and meeting the stringent food hygiene requirements of international markets.

05 High quality

The HSP3000 uses an aluminum alloy shell and aviation-grade component interfaces, making it durable, stable, and easy to maintain, extending the service life of the equipment and enhancing overall production efficiency.

06 CE, RoHS certification

All Lead Fluid products are CE and RoHS certified, meeting the safety and environmental requirements of the European market, and complying with the technical standards and hygiene regulations of the international market.

07 15 patents

The HSP3000 has obtained 15 patent authorizations, including 3 invention patents, 6 utility model patents, 5 industrial design patents, and 1 software copyright. This series of patents not only highlights the HSP3000’s leading position in technological innovation, design aesthetics, and software development but directly translates technological advantages into product performance enhancement, bringing excellent user experience and value to users.

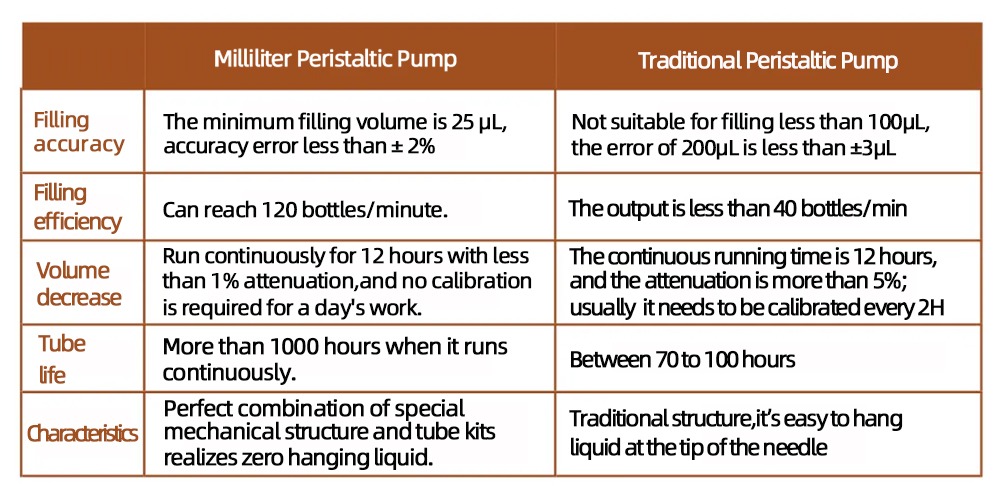

Performance Comparison between HSP3000 and Traditional Peristaltic Pumps

Lead Fluid’s Leader and Founder Mr. Zhang Yanfeng, with his deep industry background of 28 years, harbors the vision of bringing Chinese-made peristaltic pumps to the global stage. Leading Lead Fluid to firmly establish itself in the domestic market and win widespread recognition, Lead Fluid bravely strode towards internationalization, with its footprint now spread across countries such as the United States, Germany, France, the Netherlands, Italy, Spain, and Australia.