Site Overview

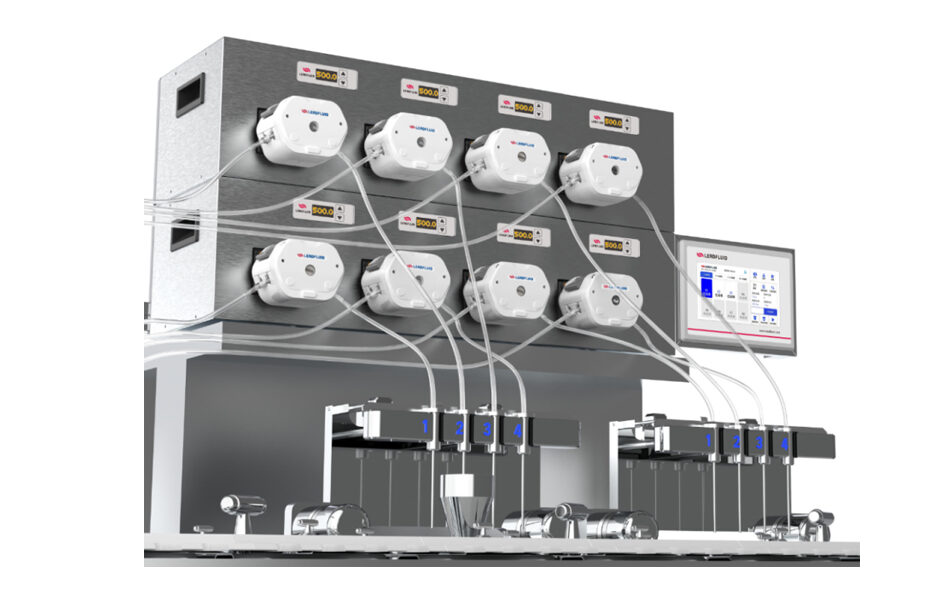

At a pharmaceutical facility in Hainan, the DS600 filling system equipped with DMD15 pump heads is accurately dispensing 5mL of medicinal solution into vials. The process demonstrates tight synchronization between equipment and production line—precise dosing, orderly vial movement, and crystal-clear solutions—showcasing a modern filling line that balances accuracy, efficiency, and compliance.

In the pharmaceutical industry, behind every filling line a strict requirement for dosage control precision, comprehensive monitoring of the entire production process, and a continuous test of the equipment’s ability to operate reliably over the long term!

How can we ensure filling accuracy while improving operational efficiency?

How can we achieve user-friendly operation and maintenance while remaining compliant?

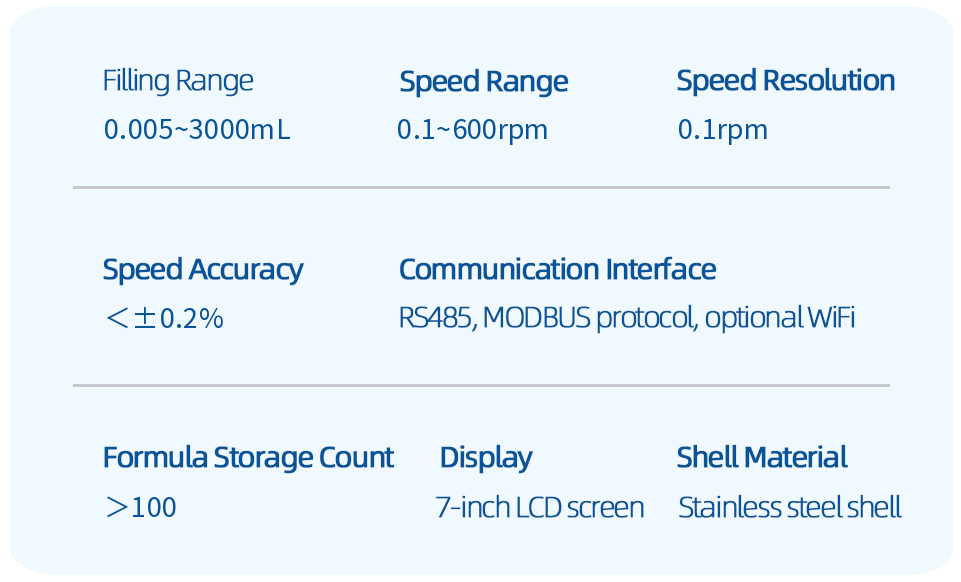

Precision: High Consistency in Small Volume Filling

For small volume medications such as injectables, oral solutions, and high-value biopharmaceuticals, filling accuracy is the lifeline of product uniformity and compliance. The DS600 abandons a single control mindset and establishes a multidimensional collaborative precision control system:

Efficiency: Modular Design Simplifies Operation and Maintenance

The efficiency of the filling system is not only reflected in the flow rate but also in the convenience of day-to-day operation and maintenance. The DS600 is designed with the principles of “Quick Change + Quick Adjustment + Quick Learning,” significantly reducing production line downtime and enhancing output per unit:

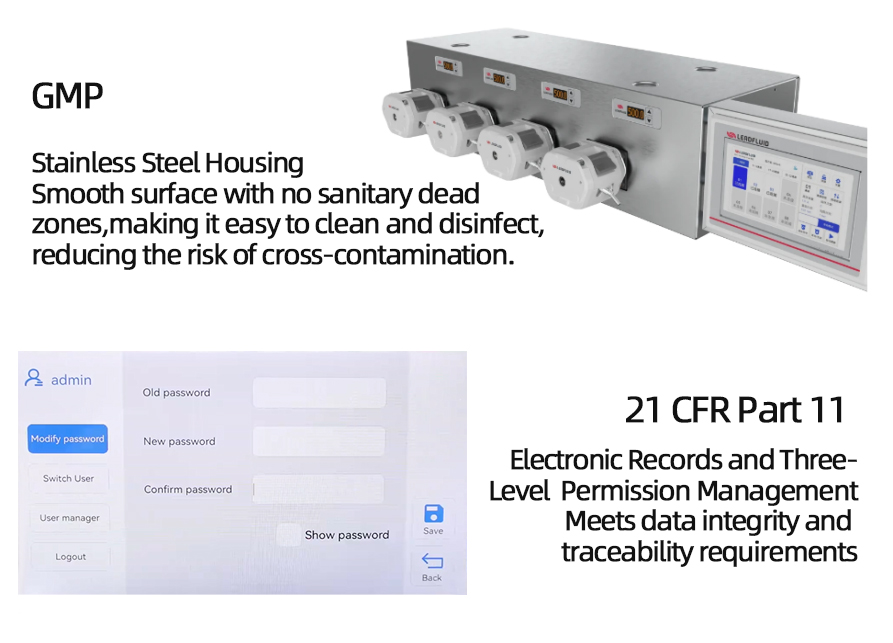

Compliance: Complete Data, Convenient Validation, Easier Traceability

In the face of increasingly stringent pharmaceutical regulatory requirements, filling equipment must not only be “capable of production” but also “verifiable, recordable, and traceable.” The DS600 incorporates multiple considerations for compliance design, including data safety, cleanliness and disinfection, and audit trails:

The DS600 filling system is designed with the principles of “simplifying operations, enhancing efficiency, and strictly adhering to compliance,” specifically tailored for upgrading or adding to existing production lines in pharmaceutical companies. It easily achieves:

01 Reliable Precision Control for Micro-Filling

02 Efficient Daily Operation and Maintenance Experience

03 Compliant with GMP and 21 CFR Part 11