FEATURED PRODUCTS

ABOUT US

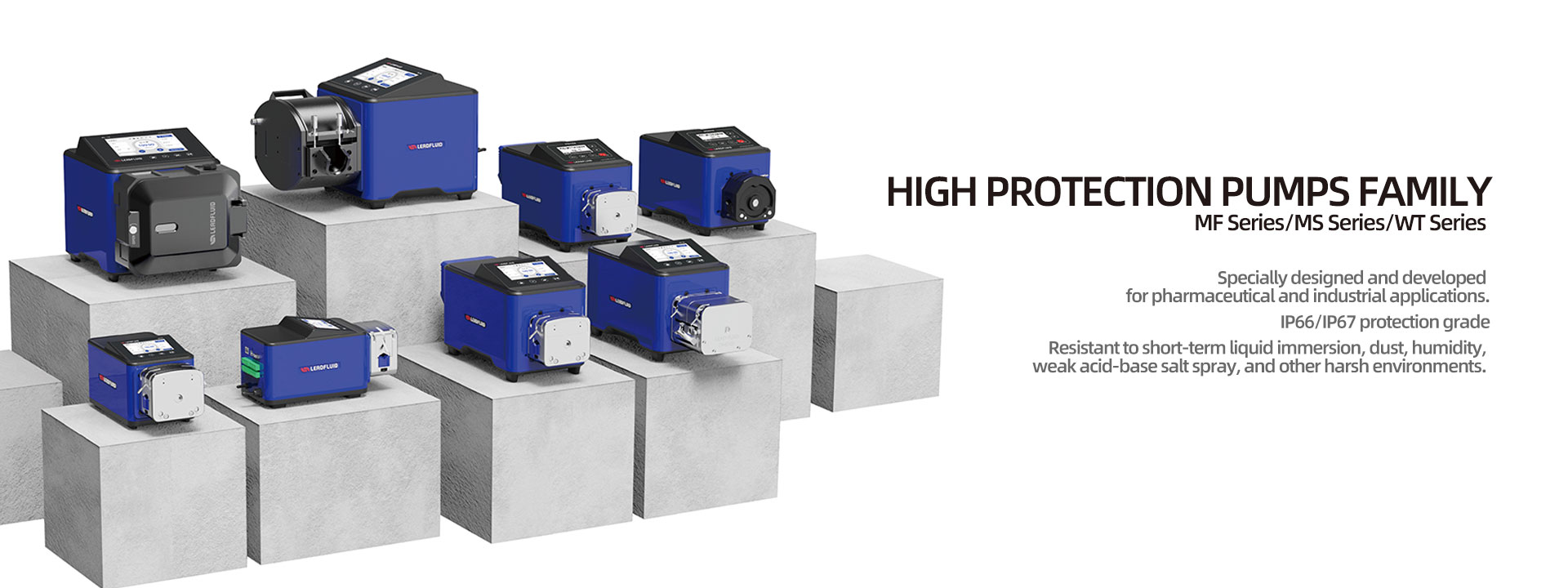

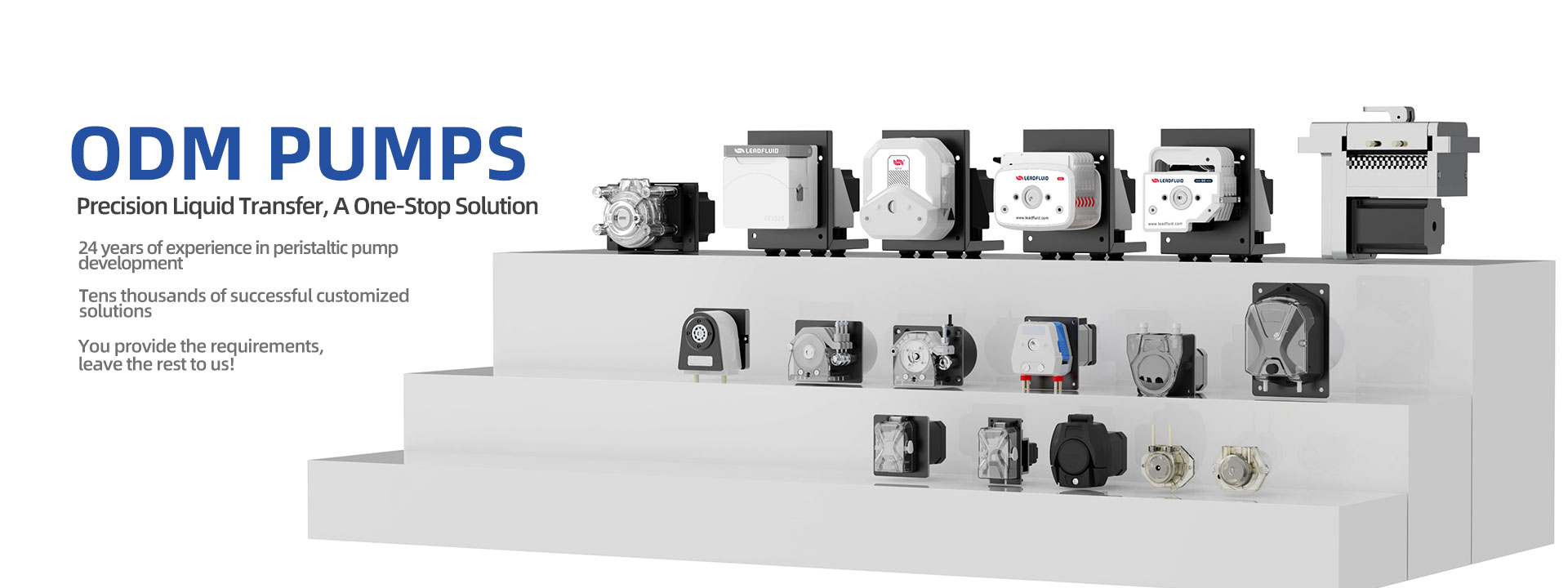

Lead Fluid (Baoding) Intelligent Equipment Manufacturing Co., Ltd. has been dedicated to pioneering research and innovation in small-scale precision pump products.We have positioned ourselves in the global high-end market, providing customers with professional and agile technical services through a comprehensive service system. With an exceptional technical team, we seamlessly tailor solutions to various application scenarios.Our products find wide application in biotechnology, environmental protection, smart manufacturing, new energy, and other technical fields for high-precision fluid transmission and control. All our products have obtained CE and ROHS certifications and are exported to countries such as the United States, Germany, France, the Netherlands, Italy, and Spain, earning widespread trust and praise from customers.

Lead Fluid sincerely hopes to move forward hand in hand with users and friends, bravely climb the peak, and create a better future.

APPLICATIONS

Biopharmaceuticals

Laboratory

Industrial Filling

Food & Juice

Printing

Sewage Disposal

CONTACT US

CALL

+86-312-6770711

8:30AM-5:00PM

Beijing Time

MESSAGE

+86-15612256761 (America)

+86-15612256251 (Europe)

+86-13313247660 (Asia)

Tel/Whatsapp

MAIL

master@leadfluid.com

We will reply your email ASAP

NEWS & INFORMATION

Research and Application of Peristaltic Pump Tubing Resistance to Different Acid and Alkali Environments

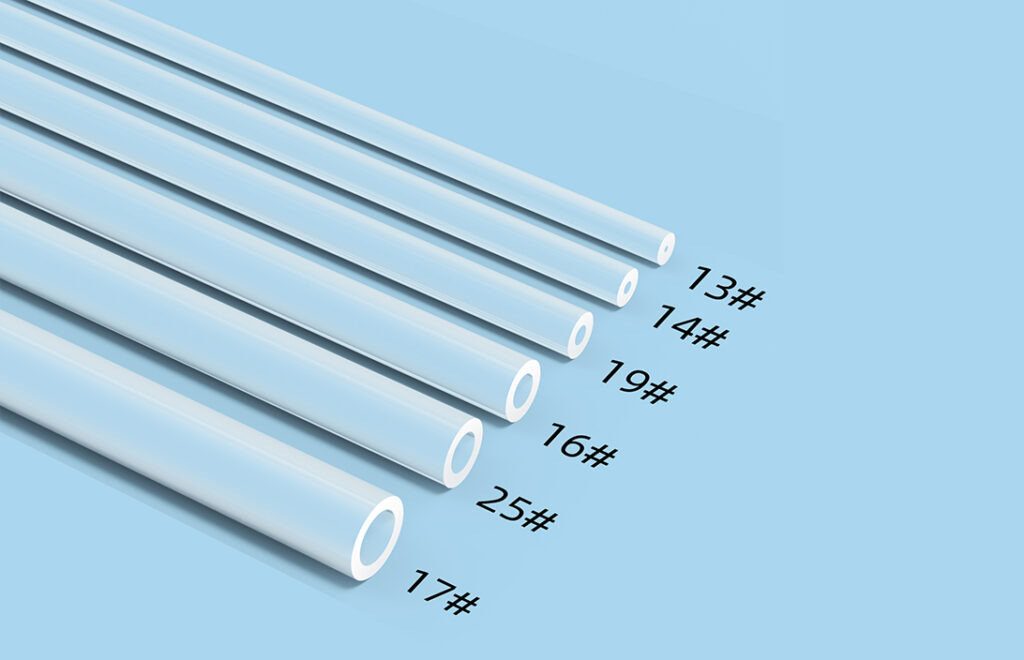

Research and Application of Peristaltic Pump Tubing Resistance to Different Acid and Alkali EnvironmentsIntroduction As a precision fluid transfer device, peristaltic pumps are widely used in chemical, pharmaceutical, food processing, and environmental protection industries. The tubing, being one of the core components of peristaltic pumps, has its acid and alkali resistance directly determining the pump’s service life and the safety of fluid transfer. This article will thoroughly examine… Read More »Research and Application of Peristaltic Pump Tubing Resistance to Different Acid and Alkali Environments

Application of Peristaltic Pumps in Coating and Granulation Industry

Application of Peristaltic Pumps in Coating and Granulation IndustryTechnical Advantages and Application Value Peristaltic pumps demonstrate unique technical advantages in pharmaceutical coating and granulation processes, becoming critical equipment for modern pharmaceutical production. Their seal-free design completely eliminates cross-contamination risks, meeting stringent GMP requirements, particularly suitable for high-value…

Application of Peristaltic Pumps in Mineral Flotation: Technical Advantages

Application of Peristaltic Pumps in Mineral Flotation: Technical AdvantagesOverview Peristaltic pumps play a critical role in mineral flotation processes, primarily for the precise delivery of various chemical reagents including collectors, frothers, depressants, and pH modifiers. Their unique pumping principle makes them ideal for reagent dosing in flotation…

Analysis of Peristaltic Pump Classification by Motor Type and Their Characteristics

Analysis of Peristaltic Pump Classification by Motor Type and Their CharacteristicsAs precision fluid transfer devices, the type of drive motor in peristaltic pumps directly affects their performance and application scenarios. Based on motor types, peristaltic pumps can be primarily categorized into four main classes, each with distinct technical features…

Analysis and Selection Guide for Peristaltic Pump Housing Materials

Analysis and Selection Guide for Peristaltic Pump Housing MaterialsPeristaltic pumps, as precision fluid transfer devices, have their housing materials directly affecting equipment durability, hygiene, and environmental adaptability. This article provides a professional analysis of three common housing materials – PPS plastic, stainless steel, and aluminum alloy –…

Ingersoll Rand Acquires Lead Fluid, Accelerating Regional Growth Strategy in Life Sciences Sector

Ingersoll Rand Acquires Lead Fluid, Accelerating Regional Growth Strategy in Life Sciences SectorNEWS Ingersoll Rand Acquires Lead Fluid, Accelerating Regional Growth Strategy in Life Sciences Sector-Strengthens Ingersoll Rand’s localization strategy through complementary acquisition-The acquisition will enhance the company’s capabilities in life sciences applications Ingersoll Rand, a global provider of mission-critical fluid…

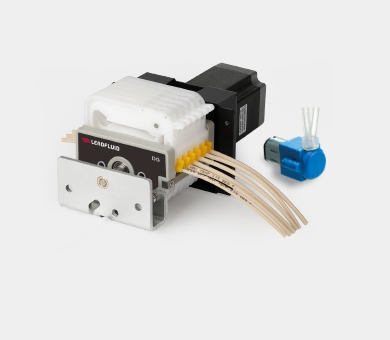

DMD15 Empowers Liquid Filling, Enabling a “Stable, Precise, and Fast” Production Line

DMD15 Empowers Liquid Filling, Enabling a “Stable, Precise, and Fast” Production LineFilling Is More Than Dispensing—It’s Key to Production Stability In the pharmaceutical production process chain, filling is a critical step that precisely distributes liquid medication into containers according to set dosages. Its accuracy, stability, and cleanliness not only ensure compliant…

-拷贝-500x500.jpg)