In spring, when all things revive, it is a “troublesome season” for many allergy sufferers. Allergens such as pollen and dust mites are frequent, highlighting the issue of allergies even more. Understanding and identifying the allergens are key to treating allergic diseases.

Fully automated immunoblot analyzer

Traditional methods of allergen detection suffer from limitations such as complexity in operation, lengthy processing times, and subjective result interpretation. The emergence of fully automated immunoblot analyzers provides a new solution to overcome these challenges in allergen detection. Through automated workflows and precise result interpretation, these analyzers offer a more reliable and convenient option for diagnosing allergens.

In the context of immunoblot analyzers, peristaltic pumps serve as the liquid transfer devices, and their performance directly impacts the accuracy of experimental results. Whether it’s adding samples, mixing reagents, or draining waste liquids, peristaltic pumps are essential for these processes. Therefore, the precision, stability, and reliability of peristaltic pumps are crucial for the performance of immunoblot analyzers.

Customer Demand

As a cutting-edge enterprise in the field of medical technology, a Hunan company specializes in providing comprehensive solutions for clinical diagnostic equipment and consumables. With the expansion of our business, we have raised higher requirements for the self-developed fully automated immunoblot analyzer’s reagent dispensing module:

The module needs to have multiple independent units to support the operation of various reagents and assays.

It should possess quantitative dispensing capabilities capable of delivering up to 1 mL of liquid.

Lead Fluid Solutions

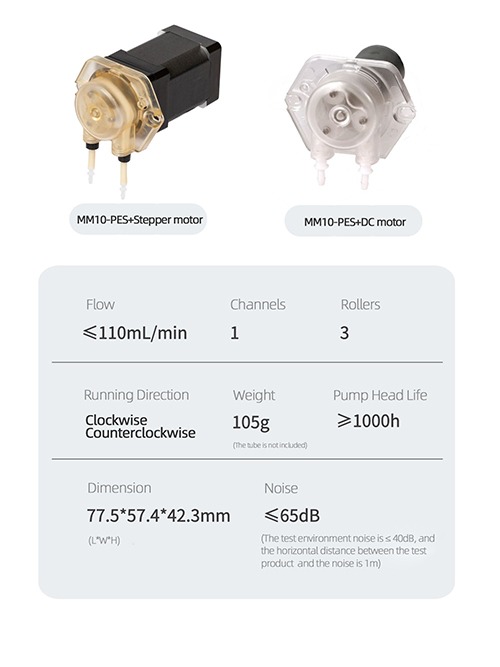

In response to the customer’s demand for the reagent dispensing module, the Lead Fluid team acted swiftly, conducting in-depth analysis of the customer requirements. After multiple rounds of technical discussions, experimental validations, and solution optimizations, we successfully matched the MM10 pump head with a stepper motor combination to meet the needs of the customer.

Compact and Easy to Integrate

The small size allows for easy integration into various compact instruments, meeting the requirements of the fully automated immunoblot analyzer for functions like micro-volume sample injection and fluid disposal.

Durable, Stable, and Cost-Effective

The pump head is made of high-strength plastic materials (PC/PES), offering high rigidity and excellent wear resistance. It can continuously operate for over 1000 hours at maximum speed, significantly reducing equipment maintenance and replacement frequency, thus lowering operational costs.

Convenient Installation with Strong Flexibility

The pump head features a unique rotary cartridge design, allowing for easy assembly and disassembly without the need for tools, simplifying the operation. Additionally, the inlet and outlet ports support installation in any orientation, enhancing flexibility.

Versatile Tube Mounting Options for Wide Applications

Two types of tube mounting options—tube connectors and tube sleeves—are provided to meet different application requirements.

Clean and Prevents Contamination

Fluid only contacts the inner wall of the tube, and the fluid path does not require valves or sealing components, which helps prevent biological waste residue and cross-contamination in the fluid path.

Customer Feedback

The Hunan company has highly praised Lead Fluid’s products. They have indicated that Lead Fluid’s products not only meet their product requirements but also demonstrate excellent performance and stability in practical use.