Introduction

• Unique spring-loaded roller body design adapts itself to tubes with different wall thicknesses and provides long tube life and easy tube installation.

• The pump head has good strength, high toughness and excellent chemical resistance.

• Stable operation and low noise, semi-transparent shell, you can observe the internal operation at any time.

• Used in medium traffic environments.

• Can be used for equipment, instruments, and laboratory.

• Convenient for ODM matching.

Parameters

Motor Type: 60 synchronous motor

Power Supply: AC220V

Wattage: ≤14W

Fixed Speed: 30rpm, 60rpm

Channel number: 1

Number of Rollers: 4 rollers (2 rollers + 2 auxiliary rollers)

Rotation Direction: Clockwise rotation

Type of Tube: Silicone, Pharmed

Method of Tube Installation: Tubing connectors

Pressure Tube Type: Fine-tunable

Pump Head Shell Material: PC

Pump Head Bottom Shell Material: PPS

Pump Head Roller Material: PES

Pump Head Roller Shaft Material: S30408 stainless steel

Pump Head Life: ≥1400h

Noise: ≤60dB (test environment noise ≤40dB, test product and noise meter horizontal distance of 1 meter)

Weight: 0.758kg (without tube)

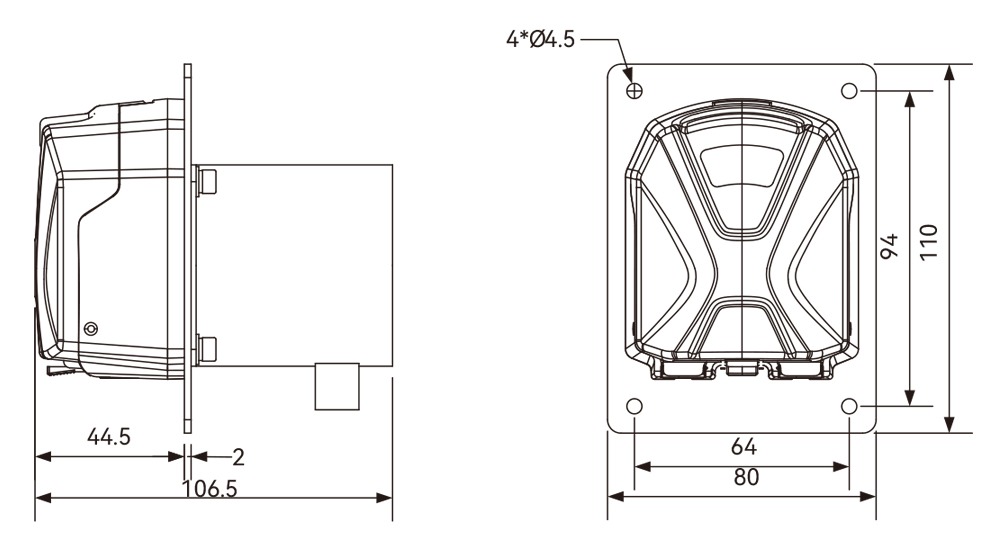

Dimensions: (L×W×H) 106.5*80*110(mm)

Working environment: Temperature 0- 40°C, relative humidity<80% RH

Storage Environment: Ambient temperature of -20 ~ +50 °C, relative humidity of not more than 95% of the clean and well-ventilated environment, the air shall not contain corrosive, flammable gases, oil mist, dust.

Suitable Tube Model and Flow Rate Reference

| Model | Speed | Material of Tube | Suitable Tube | Tube ID | Maximum Flow |

| T030A2KT15 | 30rpm | Silicone tube | 13# | 0.8mm | 1.8 mL/min |

| 14# | 1.6mm | 7 mL/min | |||

| 19# | 2.4mm | 13.5mL/min | |||

| 16# | 3.1mm | 18 mL/min | |||

| 25# | 4.8mm | 50mL/min | |||

| 17# | 6.4mm | 76ml/min | |||

| T060A2KT15 | 60rpm | Silicone tube | 13# | 0.8mm | 3.6ml/min |

| 14# | 1.6mm | 14ml/min | |||

| 19# | 2.4mm | 27 ml/min | |||

| 16# | 3.1mm | 36ml/min | |||

| 25# | 4.8mm | 99 ml/min | |||

| 17# | 6.4mm | 152 ml/min |

The above data is obtained from the test of purified water with a Lead Fluid tube under normal and pressure conditions in the laboratory. This data is for reference only.

Due to pressure in actual use, temperature, medium characteristics, tube material and other specific factors, the specific situation needs to consult our engineers.

Product Structure & Usage Method

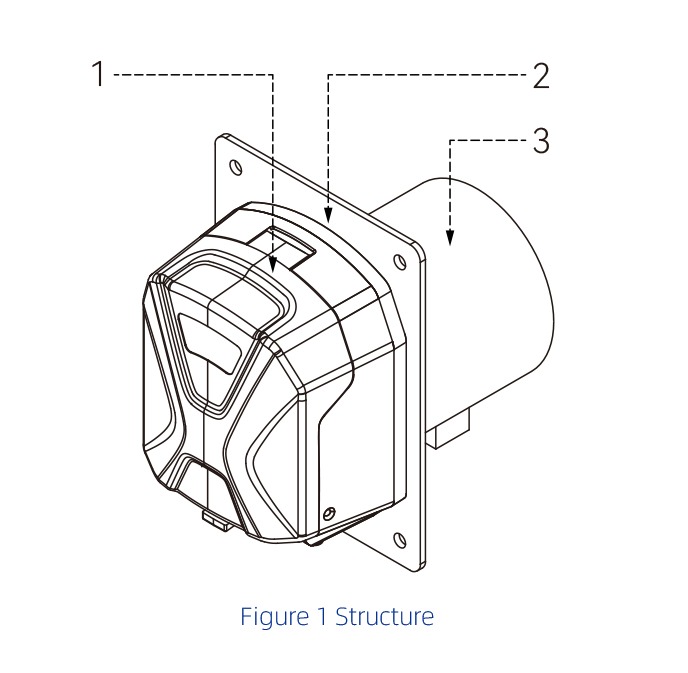

Product Structure

Component Name and Function

1.Pump Head: Installation of a tube to transfer liquid.

2.Mounting Plate: Connects the motor to the pump head and also allows the product to be mounted on other equipment.

3.Motor: Provides power.

Usage Method

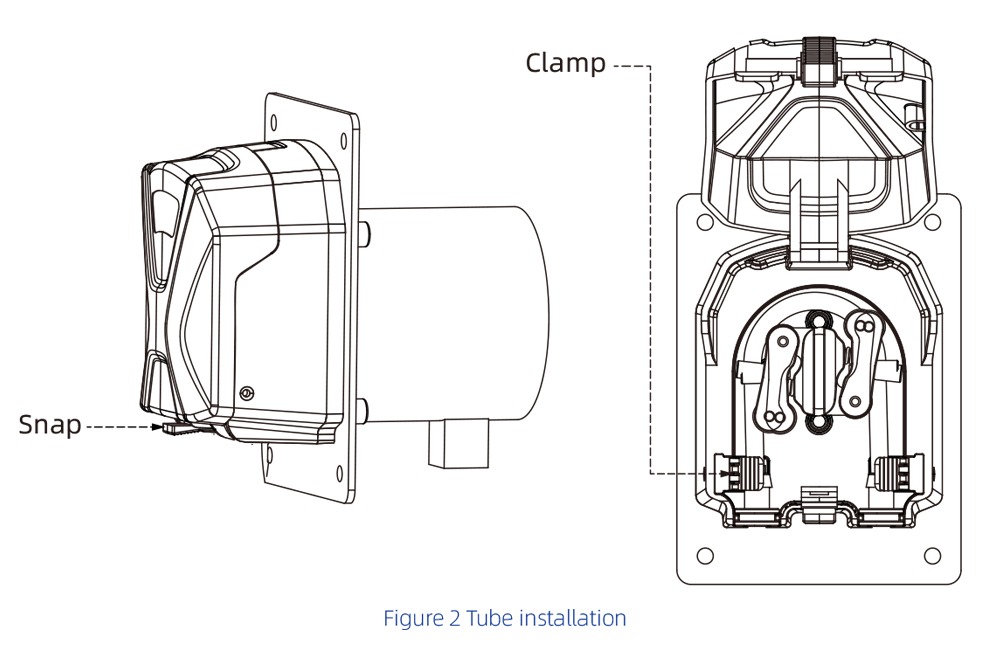

Tube Installation

Press the snap to open the pump head shield, open the tube

clamp to install the tube into the pump head, and cover the

pump head shield after the tube installation is completed.

Dimension

unit:mm