■ Shell of pump head adopts PPS material, roller adoptes PVDF material. It has excellent chemical corrosion resistance and high temperature resistance.

■ Clamshell design,change the tube convenient,simple operation.

■ Compact structure, small size, beautiful appearance.

■ Matching 42 stepper motor,convenient installation,noise is small, suitable for micro flow transmission, easy to use in OEM.

Pump Head Material

Shell PPS

Roller PVDF

Specification

| Flow range | 0.01~43ml/min |

| Speed range | 0.1~100rpm |

| Tube size | Wall thickness 0.8~1mm, ID≤3.17mm |

| Channel | 1 |

| roller | 4 |

| Tubing Method | Whole Tube(pipe clamp fixed) |

| Clearance Adjustment | Fixed clearance |

| Motor | 42 stepper motor |

| Transmission Pressure | ≤0.1MPa |

| Working enviroment | Temperature 0~40℃,relative humidity<80% |

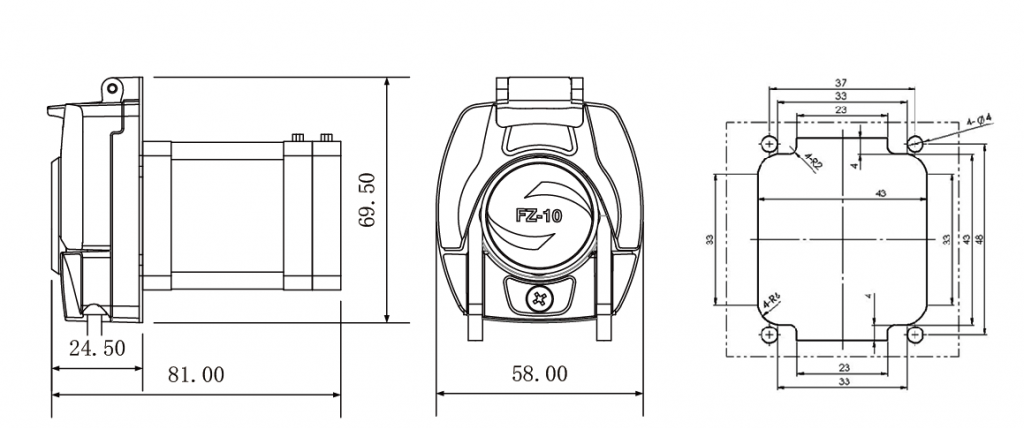

| Pump head dimension | 69.5×58×24.5mm |

|

|

Flow Rate Parameters

Tube material: Silicone, Pharmed Wall thickness 0.86~1mm

| ID (mm) | 1 | 1.52 | 2 | 2.79 | 3 |

| mL/rpm | 0.06 | 0.12 | 0.3 | 0.35 | 0.43 |

| mL/min(continuous working max 100rpm) | 6 | 12 | 30 | 35 | 43 |

★ Above flow parameters are obtained by transferring pure water under room temperature and pressure, in actually using it is effected by specific factors such as pressure, medium etc. Above for referenct only.

Motor Specification

| 42 Stepper Motor | speed 0.1-100rpm |

| step angle 1.8° \phase 2 \phase voltage 6.44V \phase current 0.7A \ phase resistance 9.2Ω±10% \phase inductor 16mH±20% |

FZ10 Dimension

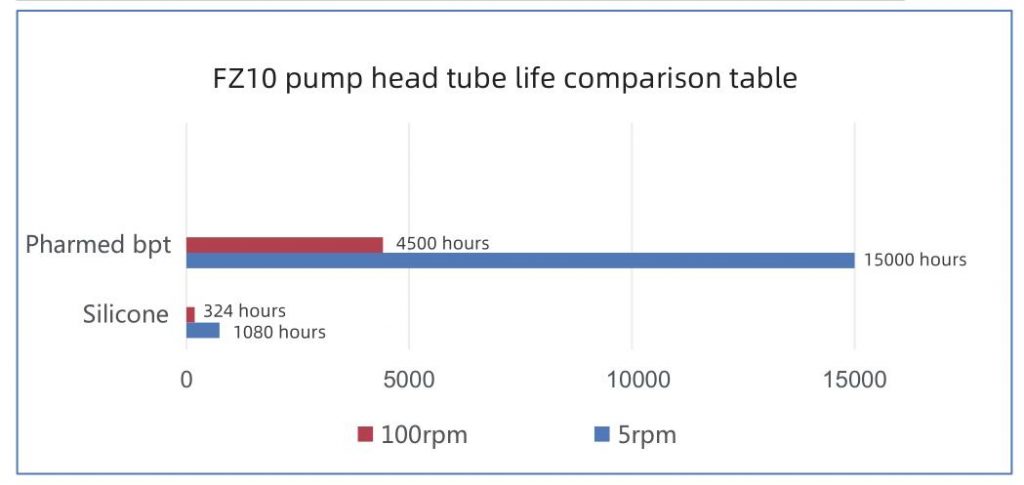

Tube life comparison table

Important tips:

A.For longer tube life, choose thicker wall tube and low speed.

B.For larger flow,choose larger ID tube and in high speed.

C.For higher precision, choose smaller ID tube and medium to high speed

D.For higher suction and back pressure,choose thinner ID and thicker wall tube and low speed.

Statement:The final explanation right of above information belongs to Lead Fluid.