Upgrade of Lead Fluid G3030 Industrial Micro Syringe Pump

New Technique

New Experience

V2.0

Lead Fluid G3030 is a high-precision OEM industrial syringe pump product that easily meets the needs of pipetting, dilution, and distribution through the precise combination of injectors and directional valves. Compared to ordinary injection pumps, industrial micro injection pumps demonstrate stronger practicality and higher flow processing accuracy in more complex experimental and industrial environments, or in the completion of multi-level automated control commands. The pipeline and injector are made of special liquid contact materials, which have stronger corrosion resistance. The open integrated installation concept makes the industrial injection pump more flexible and diverse in supporting applications.

Lead Fluid G3030 Upgraded Functions

Upgraded appearance, completely refreshed

A brand new sandblasted shell, not only beautiful, but also corrosion-resistant and scratch resistant! Overall, it is lighter and the installation holes are flexible and adaptable to various methods.

Multiple valve options, free to choose from

Suitable for common 3, 4, 6, and 9 channel valves on the market, more production scenarios, and easy response.

Unique instruction set for easy replacement

A brand new instruction set that is compatible with the Tecan instruction set, making it easy to replace and eliminating tedious adaptation work, making your work more efficient.

Equipped with high-precision feedback system, precise and efficient

Superb precision control capability and no dead volume, providing a more accurate and stable operating experience while preventing cross contamination.

Original system software, stable and reliable

The system software of G3030 has been awarded the Computer Software Copyright Registration Certificate by the National Copyright Administration, providing you with a stable and reliable operating experience, and helping to improve work fluency.

More functional features of the Lead Fluid G3030

1.Precision core components bring dual improvements in lifespan and performance

2.Cutoff speed, injection speed, circulation, etc. can all be personalized through programming

3.Excellent electromagnetic compatibility and anti-interference performance. The liquid contact components such as the injector and valve body are made of borosilicate glass and PTFE, which are compatible with the chemical corrosiveness of most fluid media

4.Supports RS485/RS232 communication, quickly realizes automatic configuration standards, can cascade up to 15 pumps, and achieve collaborative work among multiple pumps

5.Intelligent limit protection, precise monitoring of pump operating range, prevention of over limit operation, providing comprehensive safety protection for equipment

6.Professional interface design to eliminate poor contact issues and ensure stable and reliable connections

7.Support OEM customization to meet the diverse needs of customers

8.Support online upgrades

Technical parameters of Lead Fluid G3030

Linear speed: 0.005mm/s~25mm/s

Running time: 1.2s~100min(Rated stroke)

Flow accuracy: ≤±1%

Pusher advance per microstep: 0.01mm/step

Channel: 1

Power supply: DC24V±10%,electric current≤1.5A

Syringe: 50uL,100uL,250uL,500uL,1mL,2.5mL,5mL

Rated stroke: 30mm (3000 step)

Control resolution: 0.01mm(step)

Valve fitting: 1/4~28UNF internal thread

Piston driving force: >6.8kg

Applicable valve: 3-port Y-shaped valve 1/4-28 threaded interface

Valve displacement time: ≤280ms

Materials in contact with fluids: Borosilicate glass, Kel~F and Teflon

Communication interface: RS`~232/RS~485,9600/38400 baud rate optional

Parameter setting: 7 digit dial switch

Signal input: 2 gates TTL Level signal input

Signal output: 3 gates TTL level signal outpump

Shell material: Aluminum alloy

Programming function:Ramp, cut-off speed, gap compensation, infuse speed, circulation,real-time termination of movement and delay, error detection, valve rotation selection, storage of 15 groups of operating modes

Working environment:temperature 15℃~40℃,relative humidity<80%

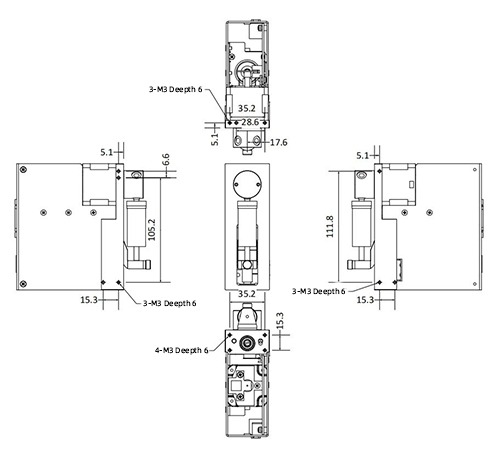

Dimension(L×W×H):134×44.5×127(mm)

Weight:1.23kg

Typical Applications of Lead Fluid G3030

The Lead Fluid G3030 industrial micro injection pump is used in medical equipment, environmental protection, and analytical instruments, and is suitable for industrial automation in the microfluidic industry for programmatic tasks.