A pulse damper can be used to relieve the pulse of a peristaltic pump, so besides the pulse damper, is there any other way to relieve the pulse? That is the Lead Fluid micro-pulsation pump head.

Patented product

Lead Fluid WMD15 series micro-pulsation pump head flow range 0.006~1700ml/min, speed range: 0.1~600rpm, suitable for 13#, 14#, 19#, 16#, 25#, 17# various tubing.

Unique micro-pulsation patented technology (patent number: ZL201420691450.5), liquid transmission pulsation is lower, transmission continuity is better, especially suitable for coating, chemical synthesis and other industries that require high transmission stability.

The whole is made of aluminum alloy and SS304 material, resistant to organic solvents and other corrosive liquids, sturdy and durable, and can work continuously at high speed for a long time.

Disadvantages of traditional pump head

In the traditional peristaltic pump head, the housing only has a transmission section, and there should be at least one roller in the transmission section. The gap between the roller and the housing at any position is equal, and the tubing is cut off.

The liquid is divided into two sections of the roller body to rotate uniformly, and the two sections of liquid flow synchronously and uniformly in the direction of rotation. But when the roller enters the transmission zone, the roller will suddenly squeeze the tubing, the volume of the tubing at the liquid inlet will change instantly, and the originally uniform flow rate at the liquid inlet will instantly decrease;

When the roller leaves the transmission area, the roller will suddenly release the tubing, the volume of the tubing at the liquid end changes instantaneously, and the originally uniform flow rate at the liquid end decreases instantaneously. Therefore, the structure design of the traditional peristaltic pump head will produce great pulsation during liquid transmission.

Lead Fluid technology upgrade

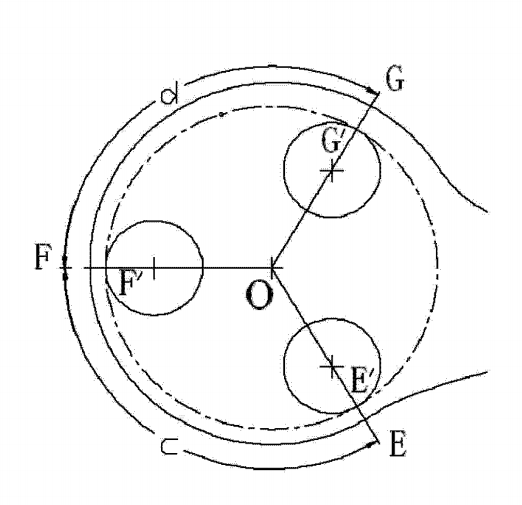

The Lead Fluid micro-pulsation pump head is driven by the roller body to rotate, by setting a number of freely rotatable rollers on the roller body, so that each roller works alternately in the slow pressure phase, the transmission phase, the slow release phase and the non-working phase.

When the roller is working in two symmetrical gradient curved surfaces, the distance between it and the shell gradually increases or decreases, and the volume change caused by the squeezing and rebound of the tubing at the roller becomes uniform. Slow process of change.

Therefore, the Lead Fluid WMD15 micro-pulsation pump head can minimize the flow rate pulsation on the inlet and outlet sides of the fluid when the fluid is transported through the pump head.

WMD15 pump head working diagram

WMD15 pump head and traditional pump head schematic diagram of flow rate pulsation curve

Pump head installation

- Open the pump head and install the tubing into the pump head

- As shown in the figure below, use M4*10 screws to penetrate the pressure plate and fix it on the bottom shell

- Cover the front shell

- Fix the pump head on the driver with 4 pump head screws.

Another way to reduce pulsation

Read article Pulsation Damper For Peristaltic Pump