Peristaltic pumps have many unique advantages: no pollution, not contact with the pump body when transferring fluid, high repeatability, low shear force, good sealing, simple maintenance, and two-way equal flow delivery capacity. Due to its non-polluting properties, it is widely used in pharmaceutical, beverage filling, hemodialysis, chemical experiments, water treatment and other fields.

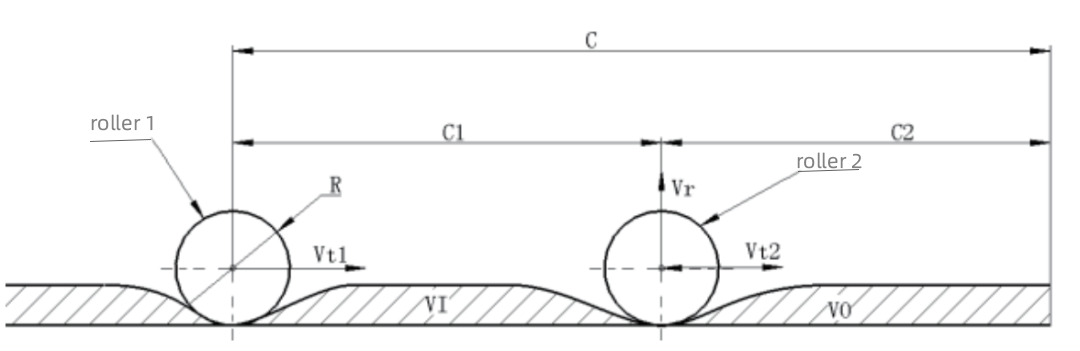

It is precisely in order to achieve the above many advantages that there are flaws in the working mode of the peristaltic pump. In the process of liquid transmission of the peristaltic pump, because the rollers need to be alternately released, negative pressure will be generated at the moment of release, which will cause a sudden decrease in the discharged liquid. Such a continuous process will cause the pulse of the peristaltic pump.

General applications may not be sensitive to pulses, but some occasions have higher requirements. For example, the peristaltic dispenser is more sensitive to the pulses of the peristaltic pump. If the glue is cut off or sucked back, it will cause uneven glue application.

How does the pulsation damper of the peristaltic pump work?

Pulse damper is a method commonly used to suppress pulses. This method is not only used in peristaltic pumps, but also widely used in other pumps.

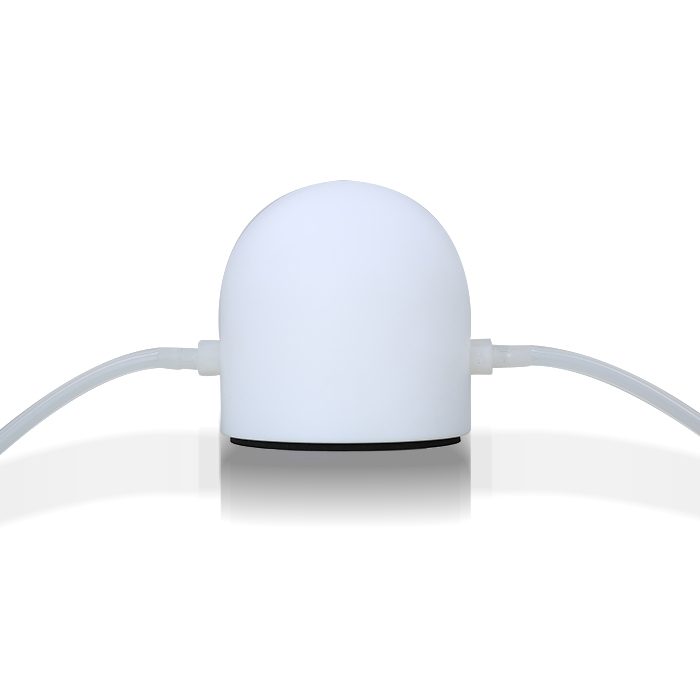

The Lead Fluid ZN90 pulse damper is a damper developed for the characteristics of a peristaltic pump. It is a pressure-bearing container, which is divided into two upper and lower cavities. The lower cavity passes through the transmitted fluid, and the upper cavity is gas. Because the gas is compressible and the pulse is absorbed instantaneously, the system can obtain a stable liquid flow and pressure, and reduce the pulsation of the pipeline.

Lead Fluid ZN90 pulse damper adopts mechanical seal, which is safe and reliable. It can be adapted to different specifications of hoses by replacing the damper connector. The material of the pulse damper can be PE-EPDM/PTFE-FFKM, which is suitable for different occasions and can be used in equipment, instruments, laboratories and other scenes.

Installation Method

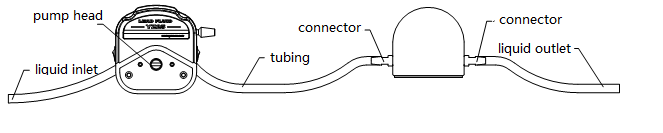

- Connect the joint with the damper

- Attach the tubing to the Lead Fluid peristaltic pump

- Start the peristaltic pump

Instructions

It is best not to adjust the flow rate too fast when the pulse damper starts to use. If the starting flow rate is too fast, it is easy to bring the gas in the damper into the pipeline, but this state will disappear after a period of time.

If the temperature difference between the transmission liquid temperature and the room temperature is large, when applying the damper, you should first slow down the flow rate and give the damper preheating or pre-cooling time, so as to prevent leakage at the threaded connection.

Precautions

The pulse damper is used in conjunction with the Lead Fluid peristaltic pump and Lead Fluid tubing, which can better reduce the liquid pulse.

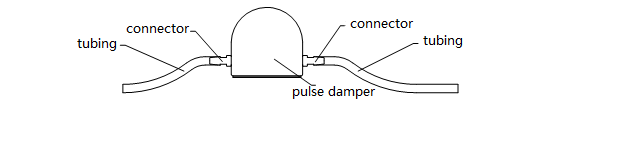

According to its own flow conditions, choosing the right pump head and tubing can make the pulse damper more effective. When installing the damper joint, it is best to choose a joint close to the inner diameter of the tubing. In order to ensure that the joint and the damper do not leak, it is necessary to wrap the raw material tape (PTFE material, anticlockwise winding) at the joint thread when installing the tubing joint. When connecting the damper to the external pipeline, make sure that the connection is well sealed.