With the rapid development of mechanization and automated production, the food industry has become one of the most promising and promising industries worldwide. In such a fiercely competitive market environment, how to improve the production efficiency and quality of products has become an important challenge faced by enterprises. The Lead Fluid DS600 series peristaltic pump filling system is equipped with YZ35 pump head and 82 # silicone tube for use in duck blood filling machines, meeting the needs of customers for high-quality, high-efficiency, and high standard filling production.

Customer Demand

Filling is a key process in the entire production process of boxed duck blood. Firstly, a reasonable and consistent filling height can ensure that the product meets the prescribed standards, maintain the stability and consistency of product quality, and improve the commercial value of the product. Secondly, the filling speed directly affects the efficiency of the entire production line, which in turn affects the profitability of the enterprise. Therefore, achieving high-precision and high-efficiency filling is crucial!

Product Advantages

High precision

The Lead Fluid DS600 series peristaltic pump filling system is driven by a high-quality servo motor/stepper motor, equipped with a stable and efficient operating system and tubelines, combined with the high-precision transmission of the YZ35 pump head, which can greatly ensure the accuracy and stability of filling.

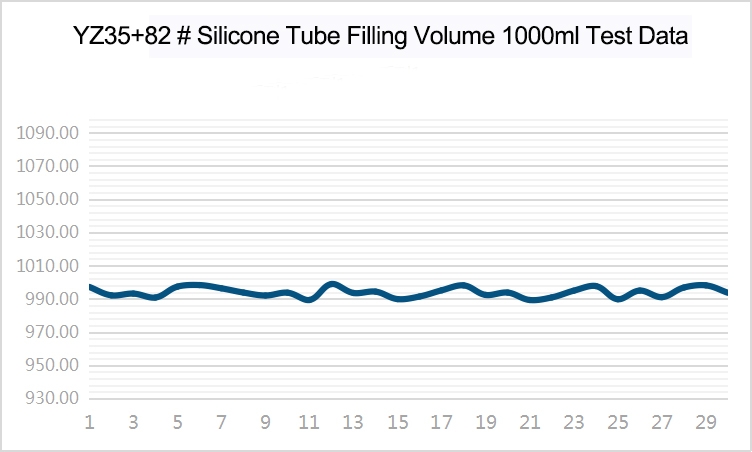

YZ35 Pump Head Experimental Data Display

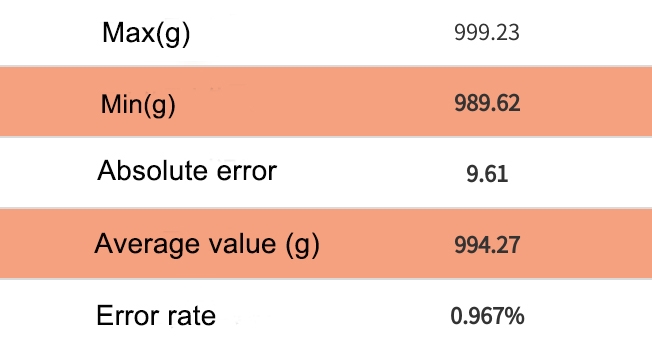

(YZ35 pump head is matched with 82 # silicone tube, and the liquid volume is set according to the liquid output at 600rpm. After verification, when the liquid output is set to 984ml, the liquid output is about 997ml, and the filling time is 4.5s. 30 sets of data are continuously tested and recorded. The above tests were conducted under the conditions of uncorrected, untreated final droplets, and a suction angle of 0 °)

Absolute error=maximum minimum value, error rate=absolute error/average value, the smaller the absolute error and error rate, the higher the accuracy. The error rate of the+82 # silicone tube on the YZ35 pump head is 0.967%.

In addition, the YZ35 pump head adopts a new type of clamping and pressure tube structure, making it easier and faster to replace the tube, and the tube will not deviate during operation. The pressure tube gap can also be adjusted according to the tube model to adapt to a small deviation in pump tube specifications.

High efficiency

Lead Fluid DS600 series peristaltic pump filling system:

- Unlimited cascading to form more channels

- Each filling head can be individually controlled, and the accuracy error between filling heads is less than 1%

- The intelligent calibration system reduces user workload, improves work efficiency, and creates a more efficient and convenient operating experience for users.

Clean, no dripping, no splashing

- The raw materials only come into contact with the pump tube, clean and pollution-free

- The suction function of the peristaltic pump ensures no dripping or splashing during the entire filling process

- Each channel has a function to prevent bottle shortage and prevent filling, ensuring that there are no bottles left, avoiding waste and pollution

- These greatly ensure the hygiene and safety of food production!

Customer evaluation

The product owner stated that:

The Lead Fluid peristaltic pump has performed outstandingly in the production of duck blood filling, bringing us tangible economic benefits and brand effects!