Antibody Reagents

Pathological diagnosis is the gold standard for disease diagnosis, while diagnostic reagents are the standard for accurate diagnosis. In medical practice, different antibody reagent results – “negative” or “positive” – mean that patients will face two completely different lives! Therefore, compared with other methodological antibodies, the preparation method and production process of pathological diagnostic grade antibodies are more stringent, especially in the filling process, which requires higher accuracy and stability.

- On the one hand, excessive or insufficient use of antibody reagents can have a significant impact on clinical diagnosis. Overuse may lead to signal saturation, increased costs, and detection errors, while underuse may result in signal attenuation, false negative results, and diagnostic delays. Therefore, the reagent filling equipment must have high precision and stability.

- On the other hand, the volume of pathological diagnostic grade antibody reagents is usually small, with only a few milliliters or even a few microliters per bottle. Therefore, the reagent filling equipment needs to be equipped with high-precision and high-quality micro filling pumps.

Customer Demand

XXX Biotechnology Co., Ltd. is a high-tech enterprise specializing in the research and development, production, sales, and technical services of in vitro diagnostic reagents and instruments. Its main business covers diagnostic products such as biochemistry, immunology, molecular, POCT, clinical testing, microbiology, and pathology, as well as upstream raw materials.

The company has developed antibody reagents for cancer pathological diagnosis, with a dose of only 20 microliters per bottle. Therefore, they need a micro filling pump that can accurately control the amount of reagent filling. In addition, it is necessary to cooperate with other systems to form an efficient production line to meet the needs of large-scale production and ensure product quality and stability.

Lead Fluid Solution

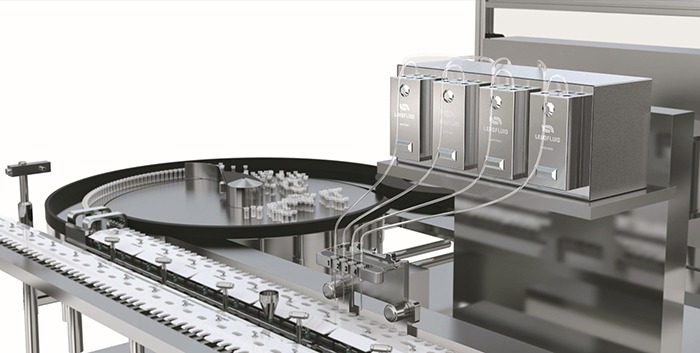

After in-depth analysis and thorough understanding of customer needs, the Lead Fluid team recommended the WSP3000 microliter peristaltic pump as the filling equipment for antibody reagents.

WSP3000 microliter peristaltic pump is a high-precision pump designed specifically for filling trace amounts of liquid, with a filling capacity range of 1 μ L~3000 μL. It has the advantages of high accuracy, high repeatability, high efficiency, high cleanliness, simple operation, and convenient maintenance.

- High precision micro liquid filling

WSP3000 micro liter peristaltic pump, innovatively designed pump head structure and control system, combined with nanoscale infusion needle, zero liquid hanging. Can achieve micro upgrade liquid filling (as low as 1uL), with a filling accuracy error of<± 0.3%. Ensure the accuracy of the amount of antibody reagents used for each filling, and avoid cost increases and resource waste caused by excessive filling.

- Modular design

Support cascading of multiple pumps to form a multi-channel filling system, with each channel having independent filling parameters, simplifying control programs, improving production efficiency and flexibility, and meeting the needs of large-scale production.

- Easy and intuitive operation

Aluminum alloy shell with strong oxidation resistance. Equipped with a 7-inch high-definition color touch screen controller, which can directly input liquid volume parameters. The operation is simple and intuitive, making it easy for operators to quickly get started and reducing human operation errors.

- High efficiency

It can be perfectly matched with automated filling production lines to achieve automatic control of filling start and bottle shortage stop. The filling efficiency of a single channel can reach 120 bottles per minute, improving the operational efficiency and stability of the production line.

- Clean and pollution-free

During the filling process, the liquid only comes into contact with the inner wall of the hose, without any dead corners, making it easy to disassemble and facilitate cleaning and sterilization. It supports CIP and SIP to ensure the aseptic requirements of the filling process and ensure product quality and safety.

- The pump tube has low wear and tear, with a continuous service life of up to 1000 hours. The 12 hour load attenuation is less than 1%, and maintenance is simple.

The Lead Fluid WSP3000 microliter peristaltic pump has obtained international patent certification, demonstrating industry-leading accuracy and innovation, providing reliable solutions for customers’ antibody reagent filling needs.

Customer Feedback

The product manager highly praised the performance of the WSP3000 microliter peristaltic pump and the service quality of the Lead Fluid team, believing that its accuracy, stability, and ease of operation greatly improved production efficiency and product quality.

For over a decade

Lead Fluid shoulders the mission of fluid transport

Through technological innovation

“Leading the new vitality of fluids”

Realize with perfect customized services