With the continuous development of science and technology, traditional Chinese medicine is also constantly integrating with modern technology to preserve its unique medical efficacy and improve the modernization level of its pharmaceutical process. The introduction of freeze-drying technology is a typical representative of this fusion process. Especially for traditional Chinese medicine extracts that require high stability of active ingredients, freeze-drying technology can effectively remove moisture from the substance, maintain its biological activity, and extend its shelf life. The importance of the filling process in the entire freeze-dried powder preparation process is self-evident, as it directly affects the quality and stability of the freeze-dried product.

The drying of Chinese herbal medicine is one of the important links in the processing of medicinal materials. The dried and processed Chinese herbal materials can effectively ensure their efficacy and facilitate transportation and storage. At present, traditional drying methods such as shade drying or air drying are mostly used for traditional Chinese medicinal materials, which have problems such as low drying efficiency, low yield, and easy pollution. And freeze-drying technology is carried out under low-temperature vacuum conditions, which can effectively avoid the damage of thermosensitive components.

The preparation process of freeze-dried traditional Chinese medicine powder includes key steps such as extraction, concentration, liquid preparation, filling, and freeze-drying. In this continuous production chain, every link is crucial and directly affects the quality and efficiency of the final product. Among them, the filling process serves as a bridge connecting liquid dispensing and freeze-drying, and its accuracy and stability play a crucial role in ensuring product quality.

The filling process not only ensures the accuracy of the liquid volume in each container, but also ensures stability, reliability, and product yield on the production line. In addition, the accuracy of filling directly affects the consistency and re solubility of the freeze-dried powder.

Customer Demand

A Biotechnology company is located in the beautiful the Changbai Mountains, focusing on the development of the whole industrial chain of mulberry and yellow, from planting, research and development to processing and sales integration. In recent years, the demand for high-quality Sanghuang freeze-dried powder in the market has sharply increased. In order to maintain product competitiveness and meet market demand, a certain biotechnology company is seeking a high-precision, stable and reliable filling system.

For the filling of Sanghuang medicinal liquid, the company has strict technical requirements:

01 Filling volume 2mL

02 Filling accuracy within 1%

03 Meet the high hygiene requirements of drug production

04 Protecting the active ingredients of Sanghuang

Lead Fluid Solutions

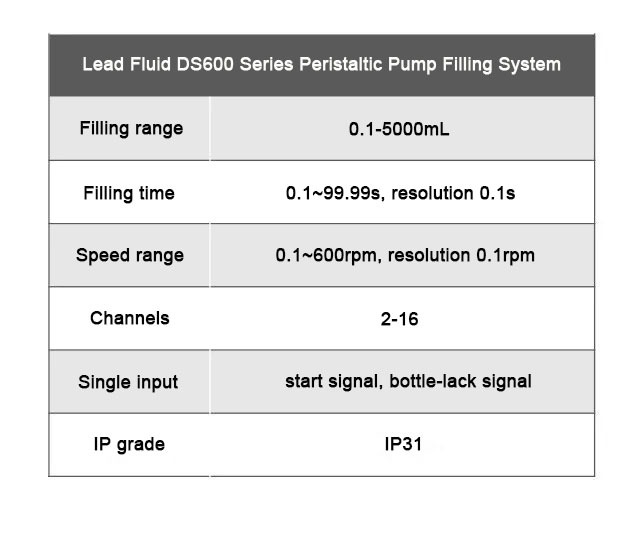

After receiving the customer’s request, the R&F team immediately conducted a professional requirement analysis and technical evaluation. After gaining a deep understanding of the preparation process of Sanghuang freeze-dried powder, R&F technical experts tailored various filling schemes for it. After careful comparison and experimental verification, the Lead Fluid DS600 series four channel filling system equipped with YZ15T pump head has become the best choice for filling Sanghuang liquid due to its high precision and multi-channel advantages.

01 Multi head high-precision filling

The Lead Fluid DS600 is designed specifically to meet the needs of multi head high-precision liquid filling. It is driven by high-quality servo/stepper motors, combined with a stable and efficient operating system and optimized pipeline design, ensuring filling accuracy.

The accuracy error between each filling head is less than ± 1%, ensuring the accuracy of the Chinese medicine liquid volume in each filling unit, thereby ensuring the consistency and stability of product quality.

02 Efficient and stable

The Lead Fluid DS600 is equipped with an intelligent calibration system, greatly reducing user workload and improving production efficiency. In addition, the system can achieve online fine-tuning of the speed, making it convenient for users to adjust the flow changes caused by hose aging. The stainless steel shell design is corrosion-resistant and easy to clean, enhancing the durability of the entire machine. Each channel is equipped with a bottle shortage stop function, ensuring the stability of long-term continuous production.

03 Low shear force

Sanghuang contains precious components such as proteoglycans, triterpenes, and flavonoids. The low shear strength of the Lead Fluid DS600 ensures that the Sanghuang liquid will not undergo qualitative changes due to mechanical force during the filling process, maximizing the preservation of the original quality of Sanghuang.

04 Clean and pollution-free

The Lead Fluid DS600 is easy to clean and disinfect, effectively preventing cross contamination and meeting high hygiene standards in drug production.

05 Strong flexibility

The Lead Fluid DS600 adopts a modular design, which facilitates multi-channel combination according to production needs and flexibly adapts to filling needs of different capacities and specifications. At the same time, it can be used in conjunction with automatic filling production lines and also supports manual operation, providing great convenience and flexibility for production.

06 YZ15T Pump Head

The YZ15T pump head is an upgraded version of YZ15, with added adjustment screws at the top and adjustable pressure pipe clearance, which can better adapt to different specifications of hoses and extend the service life of hoses. Adding a pipe clamp linkage mechanism, which retracts the pipe clamp towards the inner side of the pipe clamp groove when the pressure block is opened, improves the convenience and operational efficiency of hose installation.

(The YZ15 pump head has been upgraded to the YZ15T pump head.

Please consult with the business manager of Lead Fluid for details.)

Customer Feedback

A Biotechnology company expressed great satisfaction with Lead Fluid filling system. By using Lead Fluid products, their product qualification rate has been significantly improved, and production efficiency has also been significantly improved.