Functions and Features

• Ultra-long tube life

Special squeezing structure reduces tubing wear, extending its lifespan by more than 100 times, lowering maintenance costs

• Stable flow rate, minimal decay

Minimal pulsation, stable liquid volume, avoiding frequent calibration and tube replacement, ensuring reliable continuous operation

• Easy tube installation, user-friendly operation

Simple tube installation design, improving efficiency and saving time

• Standard tubing kits

High versatility, easy maintenance, cost reduction

• Transparent top cover, real-time monitoring

Intuitive visible design, clear view of work status

Technical Specifications

Technical specifications: 0.003~230mL/min

Speed range: 0.1~300rpm

Speed resolution: 0.1 rpm (speed ≤ 100 rpm), 1 rpm (speed > 100 rpm)

Tubing specifications: 13# 14# 19# 16# 25# 17#

Function features: Control speed, forward/reverse rotation, start/stop, full-speed

Squeezing unit material: Aluminum alloy

Gap adjustment: Adjustable

Flow rate decay: Continuous operation 100 hours decay ≤ 2%

Analog input: 0~5V/0~10V/4~20mA

Analog output: 0-5V

Input interface: DC5-25V

Output interface: Start/stop signal, direction signal, alarm signal

External digital communication: RS485 communication, compatible with Modbus protocol

Power voltage: AC100-240V,50Hz/60Hz

Power: <40W

Operating temperature: Ambient temperature 0~40°C, relative humidity < 80%

Protection rating: IP31

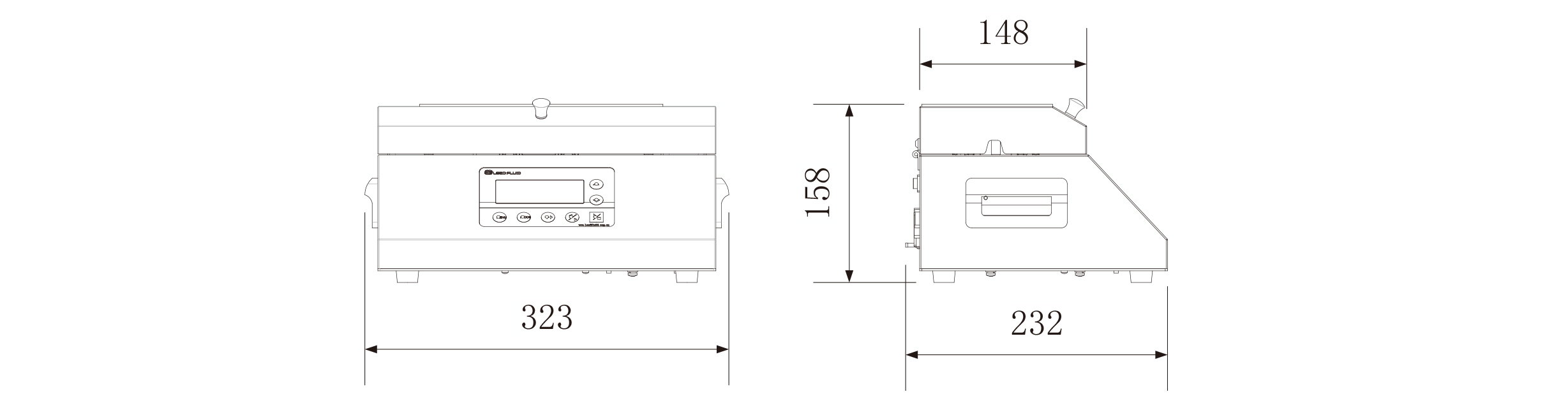

Dimensions (L×W×H): 323mm×232mm×158mm

JS1502 Continuous Transmission Squeeze Peristaltic Pump Flow Parameters

Tubing material: Viton, silicone tubing

1.6mm wall thickness

| Tubing | 13# | 14# | 19# | 16# | 25# | 17# |

| Tubing ID (mm) | 0.8 | 1.6 | 2.4 | 3.1 | 4.8 | 6.4 |

| mL /rpm | 0.003 | 0.04 | 0.13 | 0.23 | 0.55 | 0.77 |

| Max (300 rpm, mL/min) | 1 | 12 | 40 | 70 | 160 | 230 |

The above data for pump head applicability, number of channels, and single-channel flow are obtained under laboratory conditions at room temperature and pressure using Lead Fluid silicone tubing with pure water. This data is for reference only; actual performance may vary depending on factors such as pressure, temperature, media characteristics, and tubing material. For specific applications, please consult our engineer.

Applications: Laboratory, Industrial, Pharmaceutical

Typical applications: Especially suitable for high-demand fields such as adhesive coating, film coating, and chemical synthesis, effectively reducing the loss of micro-particle liquid transfer.