Peristaltic pumps, also known as tube pumps or hose pumps, operate on a fascinating principle that mimics the natural process of peristalsis observed in biological systems such as the human digestive tract. This innovative pumping mechanism is the backbone of peristaltic pumps, enabling them to precisely and efficiently transfer fluids across various industries. Let’s delve into the principle behind the functionality of peristaltic pumps.

The Peristaltic Motion:

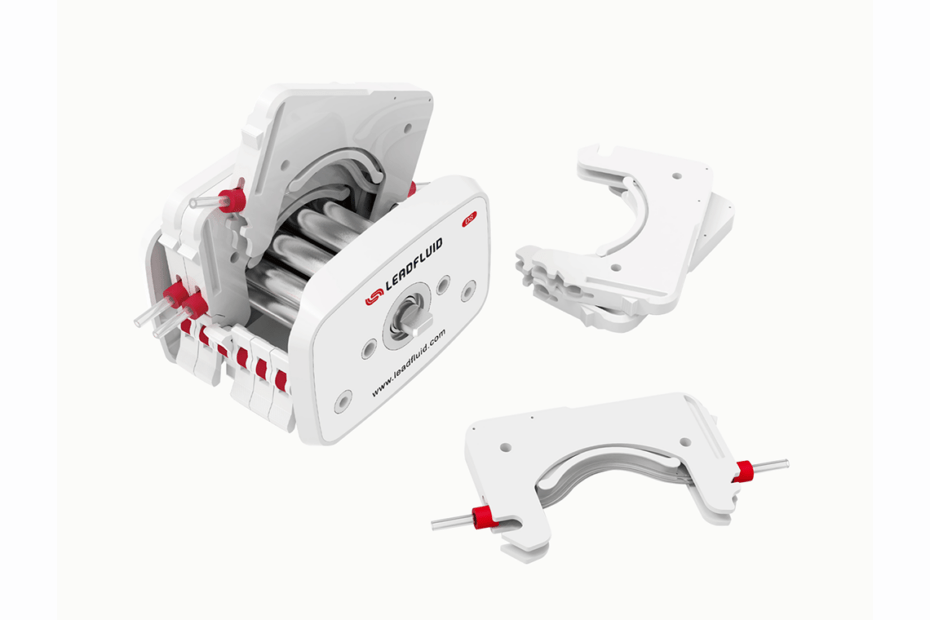

At the heart of a peristaltic pump lies a flexible tube or hose, often made of materials like silicone or thermoplastic elastomer, which is squeezed and released in a rhythmic manner to propel the fluid through the tube. This squeezing and releasing action is akin to the rhythmic contractions and relaxations of muscles observed in peristalsis.

Working Principle:

1.Tube Compression: The process initiates with a section of the flexible tube being compressed by a series of rollers or shoes arranged along the pump’s housing. As the rollers apply pressure on the tube, it becomes occluded, effectively closing off the fluid flow path at that point.

2.Fluid Propulsion: As the rollers continue to move along the tube, the occlusion progresses in a wave-like motion, squeezing the fluid within the tube and propelling it forward. This action creates a positive displacement effect, where a fixed volume of fluid is pushed through the tube with each occlusion.

3.Tube Recovery: Once the rollers pass, the compressed section of the tube recovers its original shape due to its elastic properties. This recovery creates a vacuum effect, causing the fluid ahead of the occlusion to be drawn into the tube, ready to be propelled forward by the subsequent compression.

Key Features and Advantages:

1.Gentle Fluid Handling: The squeezing action of peristaltic pumps is gentle on the fluid being pumped, making them suitable for handling shear-sensitive, viscous, or delicate fluids without causing damage or degradation.

2.Contamination-Free Operation: Since the fluid only comes into contact with the interior surface of the tubing, peristaltic pumps offer contamination-free pumping, making them ideal for sterile or hygienic applications such as pharmaceutical production or food processing.

3.Precise Flow Control: The flow rate of a peristaltic pump can be accurately controlled by adjusting parameters such as the speed of the rollers or the diameter of the tubing, allowing for precise dosing and dispensing of fluids.

4.Versatility: Peristaltic pumps can handle a wide range of fluids, from corrosive chemicals to viscous slurries, making them versatile across various industries including medical, laboratory, industrial, and environmental sectors.

Conclusion:

In essence, the principle of peristaltic pumping embodies a remarkable synergy of engineering ingenuity and biological inspiration. By harnessing the rhythmic motion of peristalsis, peristaltic pumps have revolutionized fluid handling processes, offering unparalleled precision, reliability, and versatility in fluid conveyance applications. Whether in medical laboratories, pharmaceutical plants, or industrial settings, peristaltic pumps continue to play a pivotal role in advancing fluid transfer technology.