Microfluidics technology, which uses microchannels (ranging in size from tens to hundreds of micrometers) to process or manipulate microfluidics (ranging in volume from nanoliters to liters), has developed into a new research field that intersects biology, physics, chemistry, medicine, fluids, electronics, materials, machinery, and other disciplines, achieving a series of micro processing and micro operations that are difficult to complete by conventional methods within the micron scale range.

In the early days, microfluidic technology was mainly used in analytical processes. In recent years, researchers have turned their attention to the application of microfluidic technology in the preparation of microspheres for various materials. Compared with traditional microsphere preparation methods, the advantages of microfluidic technology are increasingly prominent: the prepared microspheres have excellent dispersibility, relatively simple equipment and operation, and the preparation process is highly controllable.

Generally speaking, a microfluidic system should include the following subsystems:

1. Fluid driven subsystem

2. Process monitoring and control subsystem

3. Microfluidic chip

4. Detection and analysis subsystem

In microfluidics, even small changes in flow rate and volume can have a significant impact on experimental results. Therefore, precise fluid control is crucial in the fluid operation of this microscopic world, and the accuracy and reliability of fluid driven subsystems have become one of the key factors affecting the entire microfluidic technology.

Customer Demand

The Technology Research Institute of a certain university is based on organic electronics, with application goals of display materials and information sensing. Facing the development strategy of the national electronic information industry, it closely adheres to the scientific frontier issues of organic electronics, solves major cutting-edge scientific problems, breaks through the bottleneck of common key technologies, and creates core competitiveness in the process.

A research group at the research institute needs to use microfluidic technology to prepare microspheres during their research. They need a device that can accurately control and inject small volumes of liquid, while also requiring high precision, stability, and ease of operation.

Lead Fluid Solution

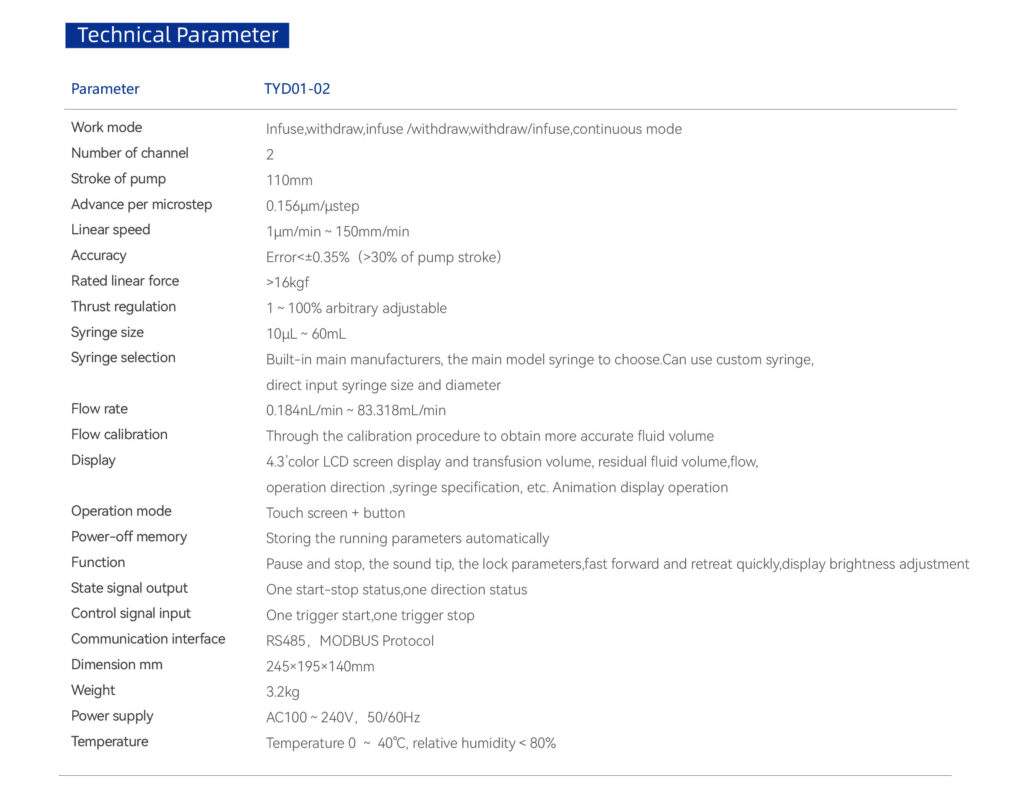

The Lead Fluid team conducted in-depth analysis of customer needs and combined with past experience in similar projects, matched the Lead Fluid TYD series laboratory injection pumps for the customer. According to the different flow rates and channel numbers, in order to meet the needs of the research group in the field of microfluidic preparation of microspheres, TYD01-02 (dual channel) laboratory injection pump was recommended.

In the field of scientific research, accurate and reliable experimental equipment is the key to research results. Lead Fluid TYD01-02 laboratory injection pump, with its excellent control system, precise mechanical structure, and powerful functions, has become an excellent choice for high-precision micro transmission of various fluids in scientific research experiments.

Functional Characteristics

*Excellent design, solid and durable

Integrated desktop design, all metal casing, durable and durable

*High strength aviation bearings, striving for excellenc

The fixing method of the transmission screw adopts high-strength aviation bearings, which significantly improves the service life of the screw compared to traditional copper sleeve bearings and has higher accuracy. The stroke control accuracy error is less than ± 0.35%

*Convenient operation and clear working status

4.3 inch high-definition LCD touch screen display and operation, while supporting screen locking. The buttons are equipped with indicator lights, the working status is clear and clear, and the buttons can be operated silently

*Multiple syringe supports, with a wide flow range

Can accommodate 2 plastic syringes or glass injection needles. Supports multiple standard syringes and can also be customized, with a syringe capacity range of up to 10 μ L~60mL, flow range 0.184nL/min~83.318mL/min

*Remote control, building automation systems

RS485 communication, compatible with Modbus protocol, can form an automatic control system with various upper computers such as computers, PLCs, microcontrollers, etc

*Stable operation, anti electromagnetic interference

Strong anti electromagnetic interference performance, capable of continuous and stable operation under high voltage electrostatic Lead Fluid TYD01-02 laboratory injection pump meets the high requirements of the research institute with its powerful performance and excellent quality, providing stable and accurate power for microfluidic research.

Customer Reviews

Statement from the supervisor of the research group:

Our research institute was very cautious in the selection of experimental equipment, and it was also after multiple rounds of comparison that we ultimately chose Lead Fluid. The results did not disappoint us, as Lead Fluid injection pump is an excellent scientific research tool!