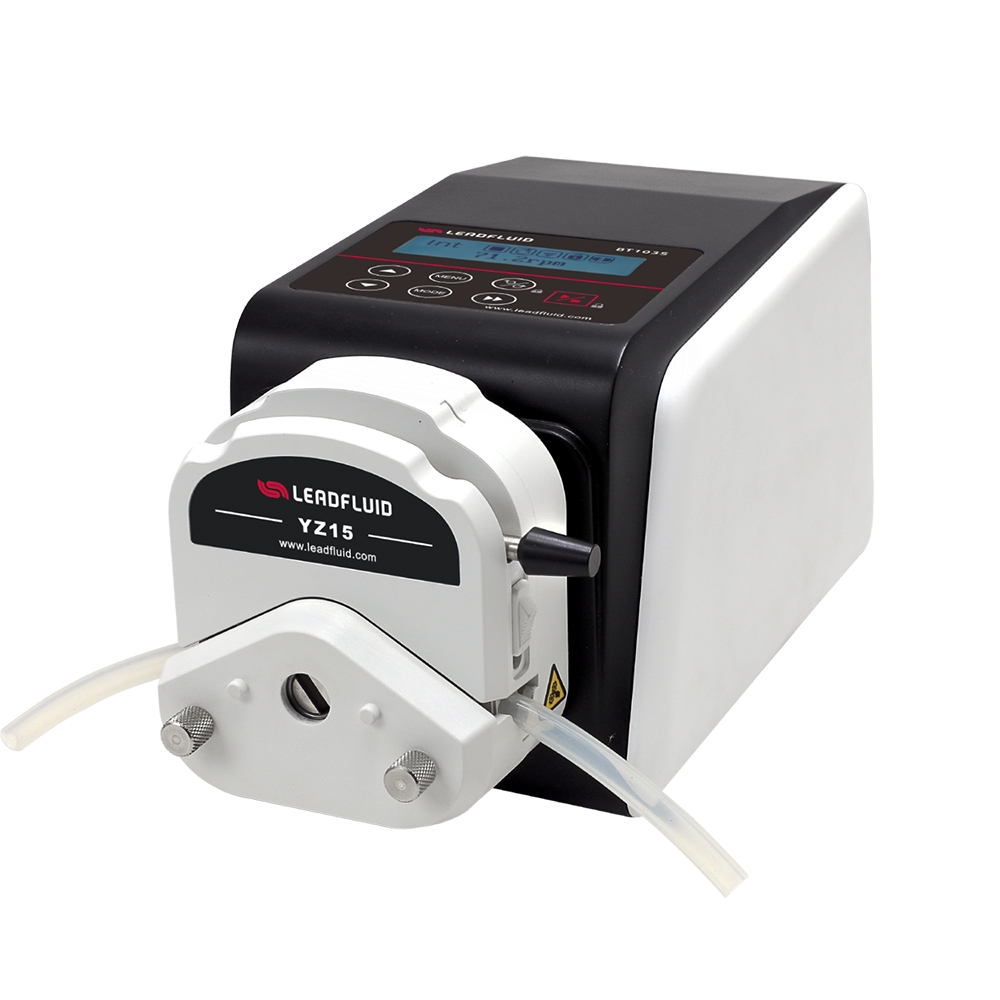

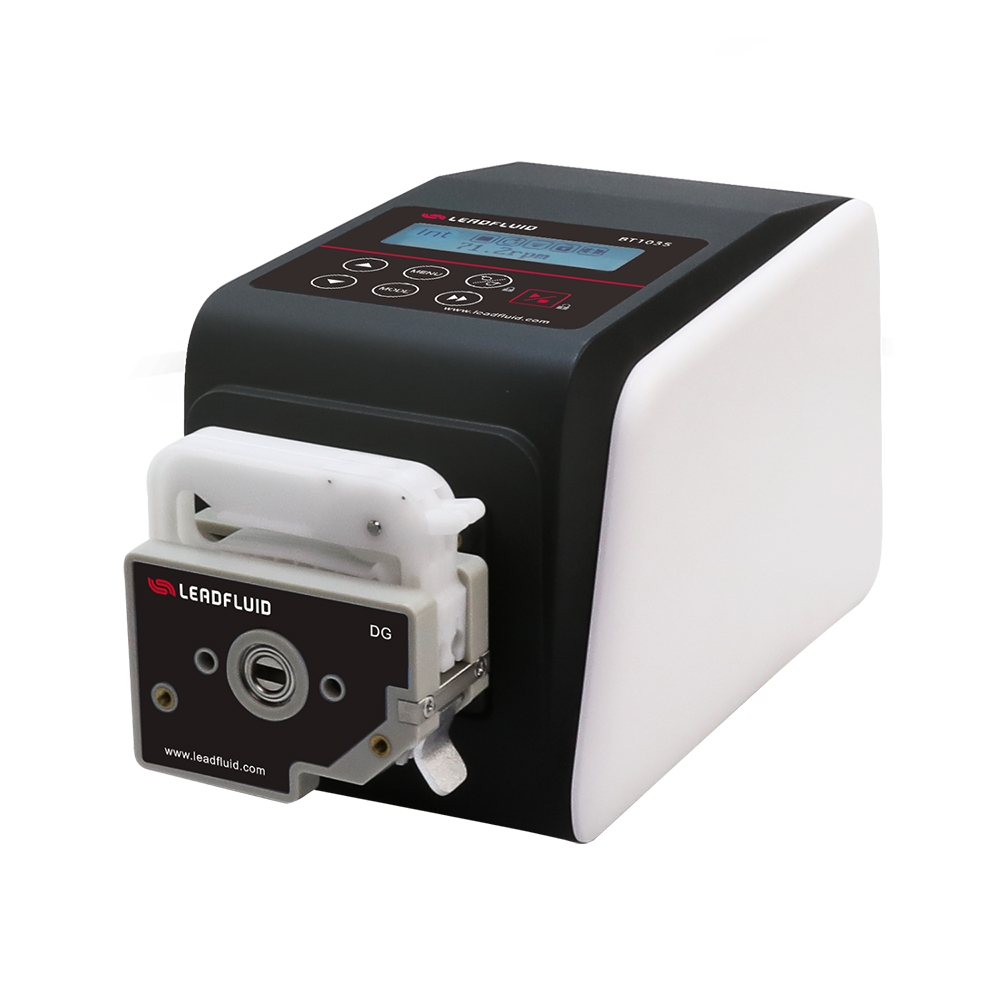

BT103S speed-variable peristaltic pump adopts high quality closed-loop stepper motor drive, speed range 0.1~100rpm, speed accuracy<±0.2%, one channel flow range 0.0001~480ml/min.

Through Lead Fluid APP software, the pump can be controlled remotely and running status can be monitored in real time. RS485 communication, MODBUS protocol is available,can be connected to upper computers such as computers, single-chip microcomputers, PLCs, frequency converters, and human-machine interfaces through a variety of signal modes to achieve systematic centralized control.

P1 Laboratory

Lead Fluid BT103S Peristaltic pump can be used in the process of sample purification and separation in the laboratory. Purification refers to the process of transforming a collective of multiple substances into a class or substance through multiple methods.

Common purification methods, such as filtration method, are based on the principle of selectively filtering various solute molecules in the solution by using a special membrane. When the solution passes through the membrane under a certain pressure (that is, it is driven by the Lead Fluid BT103S Peristaltic pump), the solution and small molecules penetrate, and the large molecules are blocked and retained in the original solution, so that the large molecular substances can be purified.

The Lead Fluid BT103S pumping liquid can provide stable pressure and flow rate, helping to efficiently complete the purification process.

The materials transported for sample purification and separation are highly sensitive, especially those with biological activity. Therefore, in the process of material transmission, it is necessary to ensure that there is no damage to the material. The Lead Fluid BT103S Peristaltic pump has a low shear force, which can effectively avoid damage to it.

P2 Reactor Feeding

Lead Fluid BT103S Peristaltic pump can be used in the feeding process of glass reaction kettle. Glass reaction kettle is a common biochemical instrument that can be used for high-temperature, low-temperature, vacuum reactions, etc.

The glass reaction kettle is an independent reaction rack with a small reserved feeding port, making the feeding process more difficult. Therefore, different materials can be pumped into the kettle through the Lead Fluid BT103S Peristaltic pump to achieve uniform and sufficient reaction effect.

The operating time, intermittent time, cycle times and other parameters can be set for the BT103S Peristaltic pump, which can meet the demand of the glass reaction kettle for regular and quantitative feeding.

P3 Sewage Treatment

BT103S Peristaltic pump can also be used in sewage treatment, supporting SBR reactor. SBR reactor is a sequencing batch bioreactor that operates intermittently for active wastewater treatment, with high nitrogen and phosphorus removal efficiency.

The Lead Fluid BT103S Peristaltic pump can deliver a fixed volume of water sample with high precision within a preset time according to the process requirements, and can automatically repeat the cycle work process, synchronizing with the operation of other equipment in the system.

It can be used to test the sewage treatment capacity of reactors, shorten the sewage treatment cycle, and improve treatment efficiency.

Meanwhile, due to the fact that sewage only flows on the inner wall of the hose and does not directly contact the pump body, the particles and chemical corrosive components present in the sewage will not affect the service life of the pump, which can effectively reduce maintenance costs.