Under the trend of global environmental protection concept development, China has put forward stricter environmental requirements for the automotive industry, with stricter emission requirements for carbon monoxide, non-methane hydrocarbons, nitrogen oxides, and PM fine particles. This is not only an important opportunity for the transformation and upgrading of the automotive industry, but also poses greater challenges to new energy material technology. As a key component material of lithium batteries, higher requirements have also been placed on the production technology of lithium battery copper foil.

Copper foil is processed by methods such as electrolysis, rolling, or sputtering, with a thickness of up to 200 μ Ultra thin copper strip or sheet below m. The thickness of electrolytic copper foil used in the field of lithium batteries is usually 6 μ M and below. Electrolytic copper foil is one of the core materials of lithium batteries, which can affect the energy density, safety, lifespan, and other indicators of lithium batteries.

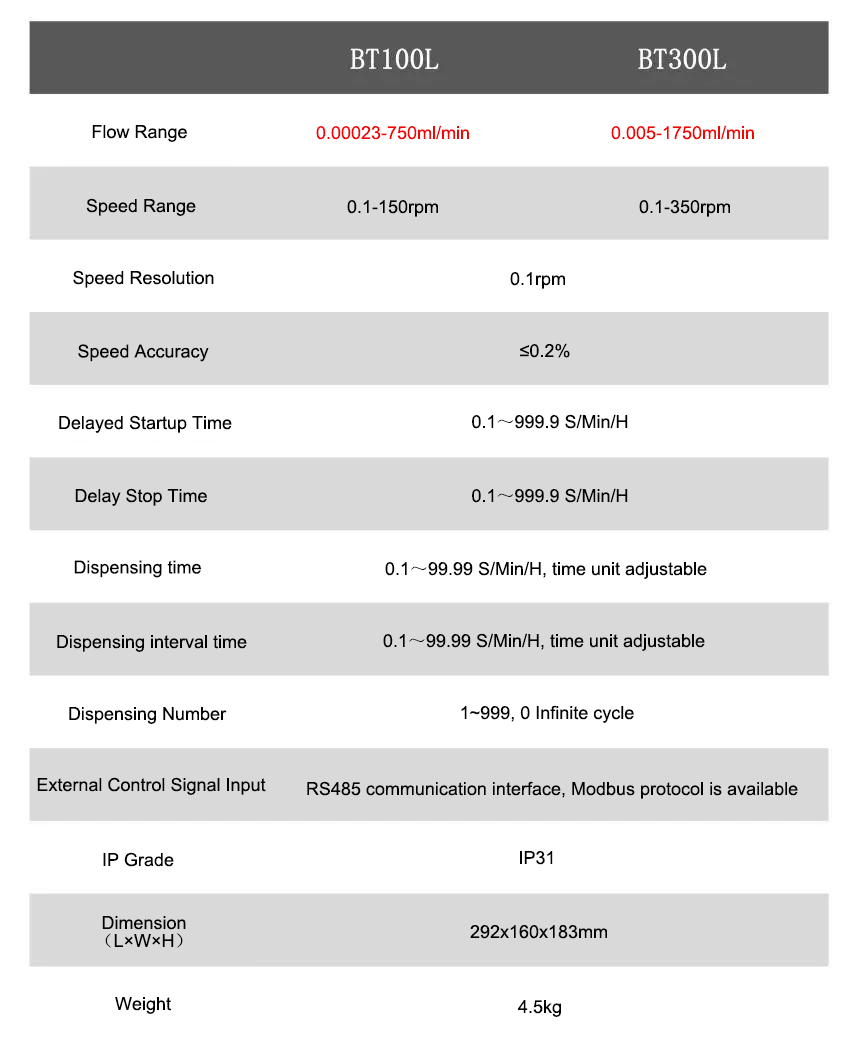

The quality and stability of electrolytic copper foil products mainly depend on the formula and addition method of additives. It can be said that additives are the core of a copper foil enterprise, and different formulations can adjust different product grain structures. Usually, additives are dispensed through manual or electromagnetic valve type dosing machines, but the accuracy is not high, which can easily lead to unstable phenomena of excessive or insufficient additives. Excessive addition can lead to an increase in slot voltage, the appearance of stripes on the rough surface of the foil, and the embrittlement of the copper foil, which can affect production quality and also cause waste, increasing production costs. Lead Fluid BT100L/300L flow type intelligent Peristaltic pump can provide accurate flow control for the input of additives, thus solving the problem that the dosage of additives in traditional methods is difficult to accurately control.

1.Customer Demand

Company A mainly engages in the research and development, production, and sales of electrolytic copper foil. The products include copper foil for lithium batteries in new energy vehicles, copper foil for electronic circuits, and copper foil for other special applications.

The company needs to purchase a batch of dosing equipment with precise flow control, high reliability, and easy maintenance to meet the needs of the copper foil production process and improve production efficiency and product quality.

2.Lead Fluid Solution

The Lead Fluid team fully considered the customer’s needs and the technical characteristics of the copper foil industry, and after comprehensive analysis and evaluation, recommended the Lead Fluid BT100L/300L flow type intelligent Peristaltic pump equipped with YZ15 pump head as the best choice for the dosing equipment.

Accurate Measurement

Compared to traditional electromagnetic valve type dosing machines, the Lead Fluid BT100L/300L has higher accuracy, with a speed accuracy error of only ± 0.2%, which can ensure the accurate input of additives and ensure the quality stability and consistency of copper foil. In addition, according to the requirements of process parameters, the Lead Fluid BT100L/300L can flexibly adjust the flow rate through the setting of relevant parameters, achieving continuous or micro dosing processes.

Long term stable operation

The use of a stainless steel shell that is resistant to organic solvent corrosion, a circuit board with special protective technology, and an anti-interference wide voltage design ensure the long-term stable operation of the equipment and reduce production risks.

Clean and pollution-free

The integrated transmission design of tube lines without valves and seals reduces the risk of leakage. Moreover, the fluid only comes into contact with the tube, avoiding blockage of the liquid with sediment during transmission, allowing the fluid to be transmitted in a more reliable, safe, and clean manner.

Easy to operate

Equipped with a 4.3 inch high-definition LCD touch screen, combined with button operation, providing users with an intuitive and convenient operating experience. At the same time, the BT100L/300 has a simple structure, is easy to maintain and clean, helps improve production efficiency and reduce downtime, and reduces production costs.

Powerful

Equipped with RS485 communication interface and compatible with Modbus protocol, it is easier to connect with other control devices and achieve systematic centralized control. In addition, it also has intelligent temperature control function, easy-to-use guided flow correction function, and unique suction function, making the entire operation process more intelligent and convenient.

YZ15 Pump Head

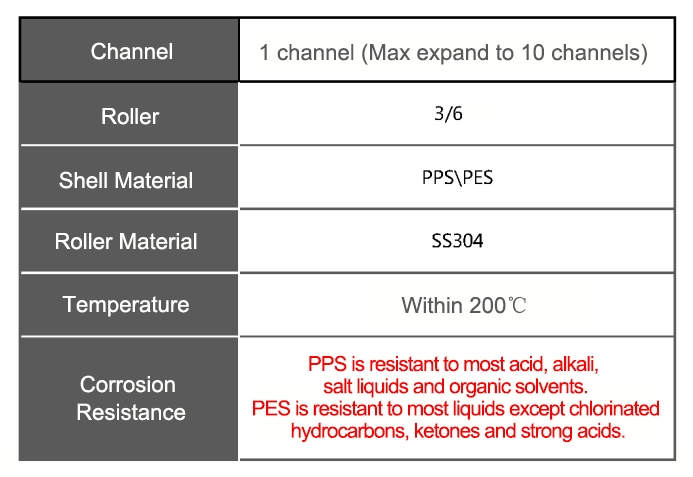

Adopting PPS/PEC special functional plastic shell and SS304 roller, ensuring that the pump head can meet high-strength usage needs such as high speed and long time;

Equipped with an adaptive clamping device, it is convenient to install tubes of different thicknesses without the need for manual adjustment;

It can achieve the superposition of multiple pump heads, and can be expanded to a maximum of 10 channels.

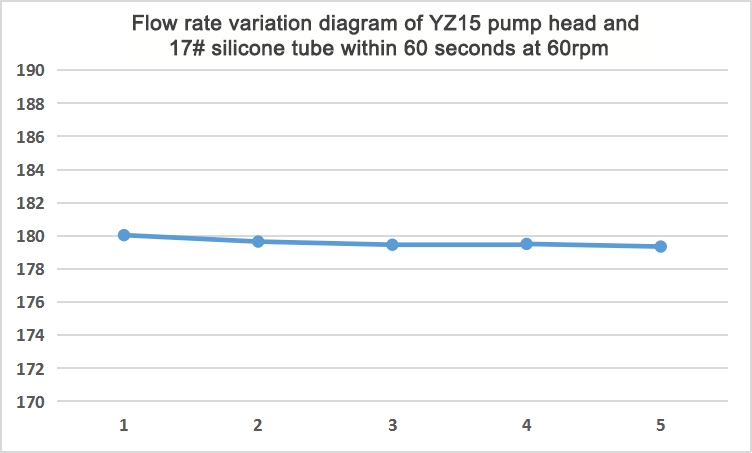

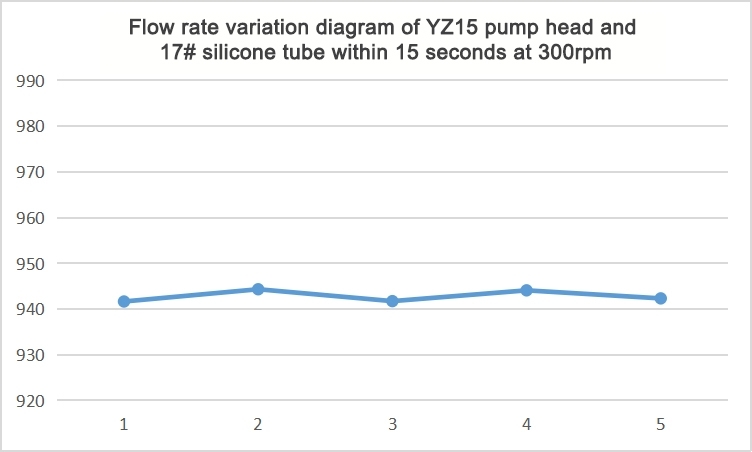

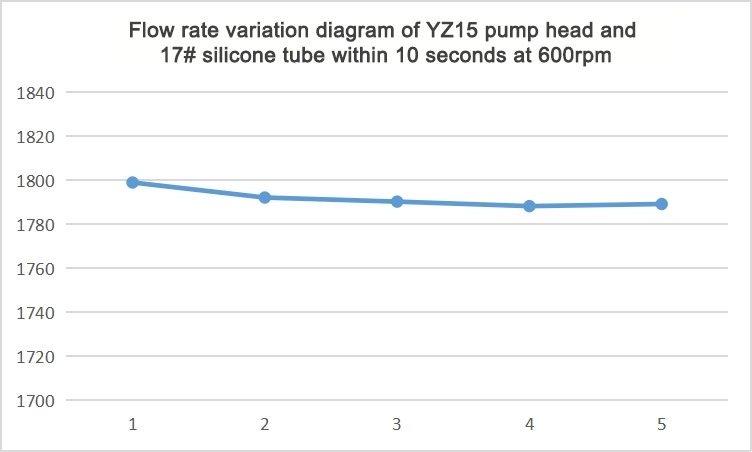

3.Data Display

4.Customer Reviews

The product manager of Company A stated:

The Lead Fluid Peristaltic pump has brought substantial improvements to our copper foil production process and met our high requirements for precise flow control. We are very satisfied with this device.