With the rapid development of mechanization and automation production, the food industry has become one of the most promising industries with great potential and market prospects worldwide. In such a competitive market environment, how to improve the production efficiency and quality of products has become an important challenge faced by enterprises. The Lead Fluid DS600 series peristaltic pump filling system equipped with YZ35 pump head and 82# silicone tube is applied to the duck blood filling machine to meet the customer’s requirements for high quality, high efficiency and high standard filling production.

Customer Demand

Filling is a key process in the production of boxed duck blood. Firstly, reasonable and consistent filling height can ensure that the product meets the prescribed standards, maintain the stability and consistency of product quality, and improve the commercial value of the product. Secondly, the filling speed directly affects the efficiency of the whole production line, and then affects the profits of the enterprise. Therefore, it is crucial to achieve high precision and high efficiency filling.

Product Advantages

1.High Precision

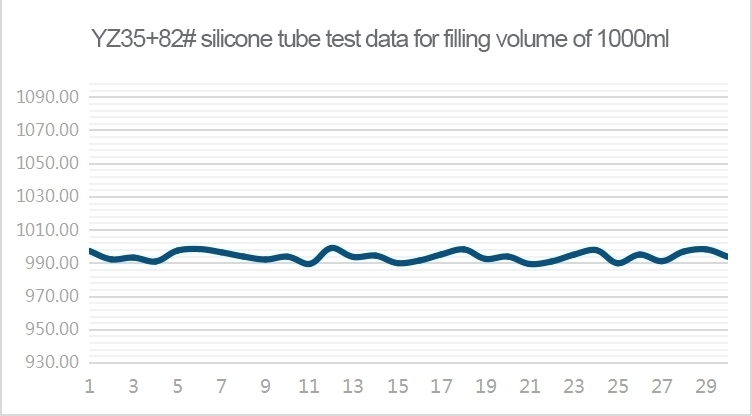

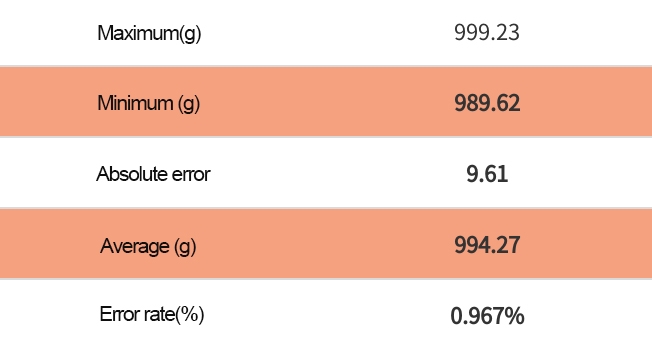

The Lead Fluid DS600 series peristaltic pump filling system adopts high-quality servo motor/stepping motor drive, is equipped with stable and efficient operating system and pipeline, and combined with the high precision transmission of YZ35 pump head, which can greatly ensure the accuracy and stability of filling.

(The absolute error of YZ35 pump head + 82# silicone tube is the difference between the maximum value and the minimum value, and the error rate is the absolute error divided by the average value. The smaller the absolute error and error rate, the higher the accuracy. The error rate of YZ35 pump head + 82# silicone tube is 0.967%.)

In addition, the YZ35 pump head adopts a new card installation and pressure pipe structure, which makes it easier and faster to replace the hose, and the hose will not deviate during the running process. The gap between the pressure pipes can also be adjusted according to the hose model to adapt to a small deviation of the pump pipe specifications.

1.High Efficiency

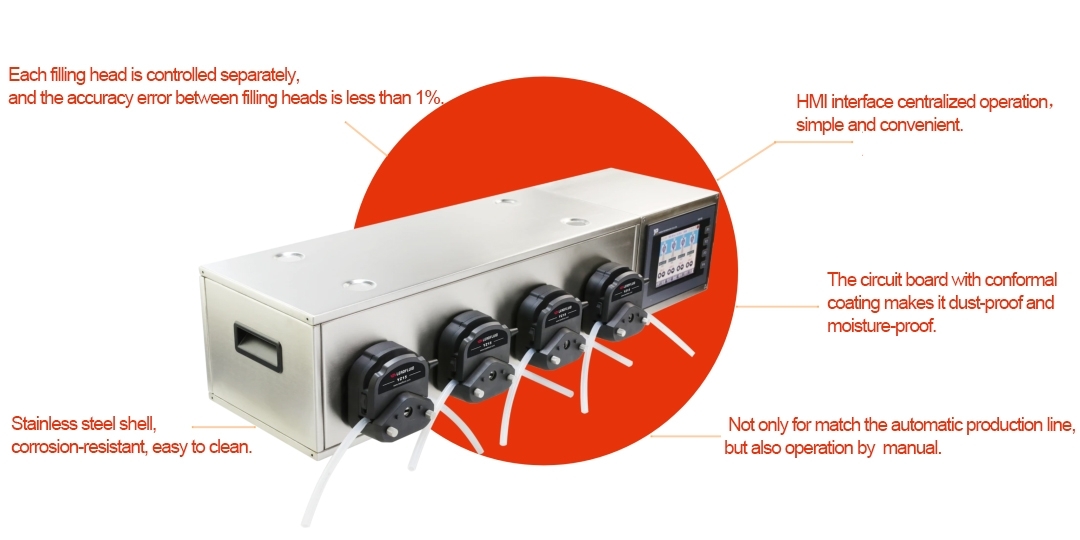

●The Lead Fluid DS600 series peristaltic pump filling system:

●It can be infinitely cascaded to form more channels.

●Each filling head can be controlled separately, and the accuracy error between filling heads is less than 1%.

●The intelligent calibration system reduces the user’s workload and improves the work efficiency, creating a more efficient and convenient operating experience for the user.

2.Clean, no dripping, no splashing

●The raw material only contacts with the pump pipe, which is clean and pollution-free.

●The suction function of the peristaltic pump makes the whole filling process without dripping or splashing.

●Each channel has the function of missing bottle stop filling, which ensures no bottle is not filled and avoids waste and pollution.

All of these greatly ensure the hygiene and safety of food production.

Customer Evaluation

The product manager said:

The Lead Fluid Peristaltic Pump has performed excellently in the production of duck blood filling, bringing us tangible economic benefits and brand effects!

For more than ten years Lead Fluid has been committed to providing customers with competitive micro fluid transmission solutions and services with technological innovation, leading the new vitality of fluid, and fulfilling the “pump with heart” through perfect customization services!