Now peristaltic pump is more and more widely used in various industries,such as pharmaceutical industrial,agriculture,packing and printing,industrial and manufacturing etc.Before, we briefly introduced the application of peristaltic pumps in liquid dispensing. This issue brings you the application of peristaltic pumps in chemical synthesis. The many advantages of peristaltic pumps make it applied in many aspects, and it also shines in chemical synthesis. Peristaltic pump is a kind of precise controllable flow rate fluid transmission and processing equipment. It has high flow control accuracy, time controllable, simple operation and easy maintenance, good mixing uniformity, and can achieve corrosion resistance according to the characteristics of different tubing and materials. No contact with the pump body can avoid cross-contamination and other characteristics.

一、Market demand

♦ Provide low-speed, stable and accurate liquid to the reactor in chemical experiments and small production. Generally, it is required to transmit one or more solutions of different components at the same time, and the respective speeds are also different.

♦ There are many kinds of solutions, many of which are highly corrosive or toxic, and the pumps are required to be corrosion resistant and have strong applicability.

♦ Some customers require that the flow can be directly displayed and controlled. Compared with the conventional speed-variable peristaltic pump, the operation is simpler and more convenient.

二、Solution

A complete product line, a strong technical team, and rich application experience can ensure that we provide customers with complete, reliable and reasonable solutions:

◊ Lead Fluid peristaltic pump can easily provide a single channel flow rate 0.0001-13000ml/min dripping acceleration.

◊ Peristaltic pumps with multiple functions can be selected: speed variable type, flow type and quantitative timing type to meet different needs.

◊ A single peristaltic pump can simultaneously transmit 1-36 channels of liquid.

◊ For different liquid components and characteristics, different tubings, pump heads, and pump body materials can be provided.

◊ For special test requirements such as high pressure, high viscosity, super corrosion, you can choose Lead Fluid gear pump and high pressure peristaltic pump.

Recommended reference model

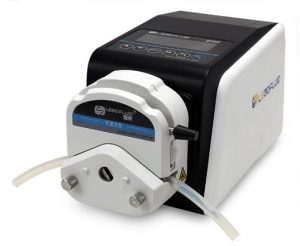

BT103S Speed-variable Peristaltic Pump

BT100L Intelligent Flow Peristaltic Pump

BT100S-1 Multichannel Speed-variable Peristaltic Pump

WG600F Large Flow Industrial Peristaltic Pump

CT3001F Precision Micro Gear Pump

|

|

|

|

三、Applications

The application of peristaltic pump in synthesis of Polycarboxylate Superplasticizer

Polycarboxylate Superplasticizer are divided into two categories, one is polyethers with acrylic or methacrylic acid as the main link branch with different side chain lengths. The other is polyethers with maleic anhydride as the main link and different side chain lengths.

Although there are many advantages and widely used today, there are still some problems:

- Strong temperature sensitivity.

- High viscosity. In the high mixing material, low water-binder ratio concrete preparation, the concrete viscosity is high.

- Strong sensitivity to the mud content of sand and gravel aggregates, poor adaptation to machine-made sand, and sensitive mixing content that affects construction.

Application in Polycarboxylate Superplasticizer

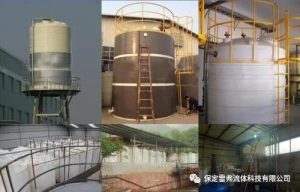

- Stably transfer polypropylene solution to the reactor. According to the different requirements of capacity and process, the transfer flow rate is generally 2-10L/H in production, and 0.5-2ml/min in small-scale test.

- Each complete production or experiment time is generally 2-4 hours.

- The peristaltic pump and transmission tubing need to be resistant to acrylic acid corrosion.

- The high temperature and humidity in the production workshop require the peristaltic pump to have high durability.

- In the pilot test, the peristaltic pump is required to dropwise add materials smoothly and accuratel

|

|

|

Lead Fluid peristaltic pump solution

In the formal production, the Lead Fluid large-flow industrial peristaltic pump is used, maintenance-free brushless DC motor, strong transmission stability, and can provide a single-channel transmission flow rate of 400-13000ml/min.

In the small test, the high precision stepper motor of Lead Fluid cooperated with the special low-pulsation pump head to provide perfect dripping effect for the test.

The intelligent flow peristaltic pump inputs and displays the flow parameters through the touch screen, has the function of accumulating the amount of dripping liquid, and the operation is simpler and more convenient than the traditional speed.

It can be resistant to strong corrosion, strong acid and alkali, high temperature, high humidity.

Recommended reference model

WG600S Large Flow Industrial Peristaltic Pump

BT101L Intelligent Flow Peristaltic Pump

BQ80S Micro Speed-variable Peristaltic Pump

|

|

|

In the application of chemical synthesis, in addition to polycarboxylic acid water-reducing agent, there are also graphene, lithium battery basic materials, etc. The Lead Fluid peristaltic pump can be easily competent, saving you time and effort.