Have you ever wondered:

Why does the actual output always slightly deviate from your 1 mL/min setting?

Why are flow rate units on pump specifications always in mL/min?

This seemingly simple “unit selection” hides profound precision control principles in fluid transfer. Today, let’ s unveil the secrets behind flow rate units!

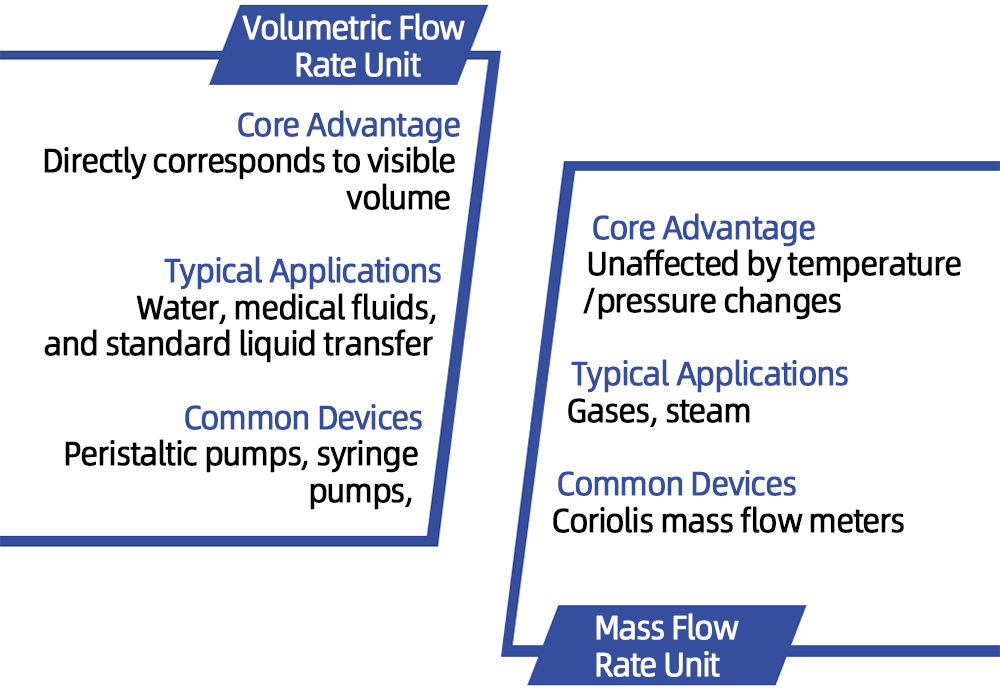

Flow Rate Units: Volume vs. Mass

In fluid transfer, flow rates are categorized into two types:

Volumetric Flow Rate

Volume passing through a cross-section per unit time (e.g., mL/min).

Mass Flow Rate

Mass passing through a cross-section per unit time (e.g., g/min).

Why Do Peristaltic Pumps Prefer Volumetric Flow (mL/min)?

Imagine pouring water—you’d say “half a cup” rather than “100 grams” because volume (e.g., “half a cup”) is visually consistent, while weight varies with density.

Peristaltic/syringe pumps typically handle water, medical fluids, or culture media, where density differences are negligible. Using mL/min (volume/time) is:

More intuitive: Aligns with operational habits.

Simpler: Eliminates redundant density calculations for each fluid.

How to Choose Volumetric Flow Units?▼

Volumetric Flow = Volume Unit ÷ Time Unit

Common combinations:

✅ Key Selection Criteria:

Required precision.

Device control capability.

Operator familiarity.

Common Pitfalls ▼

Mistake 1: Setting Values Below Minimum Stable Flow

Each pump has its own minimum stable flow threshold, which is determined by the pump structure, tubing resilience characteristics, and drive precision:

Standard peristaltic pumps: The lower limit of stable flow typically ranges at the mL or µL level.

Precision syringe pumps: The lower limit of stable flow can reach the nL or pL level.

If the set value falls below this range, intermittent delivery, output fluctuations, or even complete flow stoppage may occur.

Mistake 2: Arbitrary Unit Conversion

Converting mL/min to mL/s for “higher precision” (e.g., 1 mL/min ≈ 0.0167 mL/s) causes:

Resolution loss: Control systems struggle with micro-adjustments.

Human error: Tiny decimals increase misoperation risks.

✅ Best Practices

- Use flow rate units that match the pump’s performance level.

- Maintain operation within the device’s recommended parameter range.

Why “Per Minute” (mL/min) is Preferred▼

01 Intuitive Operation

Using “per minute” measurements (e.g., “5 mL/min”) aligns better with daily cognition and operation habits compared to “per second” units (like “0.083 mL/s”), making it easier to understand, remember, and set.

02 Control-Friendly

Most control systems don’t require second-level responsiveness. Measuring in “minutes” improves resolution, enables smoother adjustments, and avoids frequent fluctuations.

03 Industry Standard

Whether for controllers, PLCs, or data logging systems, the vast majority default to mL/min as the flow rate unit, ensuring standardized interfaces and rapid deployment.

04 Matches System Inertia

Liquid delivery systems inherently possess inertia. Using “per minute” as the unit helps minimize potential fluctuations caused by overly frequent adjustment commands.

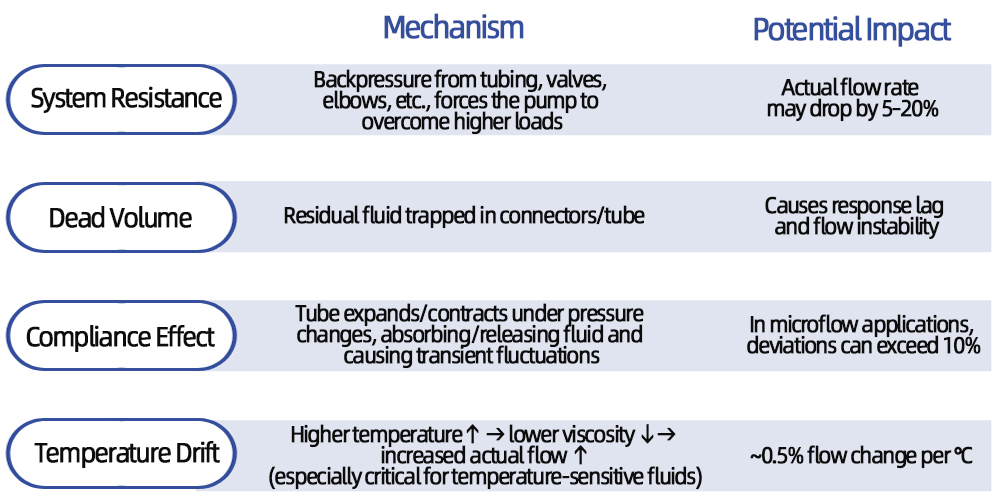

Why Actual Output ≠ Set Value?▼

Key factors causing deviations:

(Note: Peristaltic pumps are inherently valveless, seal-free, and dead-volume-free, but flow deviations often originate from external system components—especially in microliter-scale applications, where these effects are amplified and must not be ignored.)

Calibration: Aligning Setpoints with Actual Output ▼

For applications demanding higher flow accuracy, calibration is an essential step. The core logic of calibration involves:

Measuring actual output → 2. Comparing with setpoint → 3. Calculating compensation factors/adjusting control parameters → 4. Improving consistency

Lead Fluid High-Protection Series & Explosion-Proof Models support two calibration modes:

1 Simple Calibration

Simple steps, fast execution

Ideal for routine use and general precision applications

2High-Precision Calibration

Longer duration, higher accuracy

Suitable for experimental research and demanding conditions

Important Notice: To ensure flow accuracy, flow calibration must be performed when: first using the pump, replacing the pump head/tubing/transfer medium, continuous operation exceeds 4 hours, significant flow deviation occurs, or ambient temperature changes substantially.

What may seem like a simple “unit” selection actually involves an entire set of mechanisms encompassing operational logic, control accuracy, and system response. Choosing the right unit is the first step toward stable delivery and precise control.

Understanding these underlying “principles” helps you avoid pitfalls and improve efficiency in fluid handling operations!