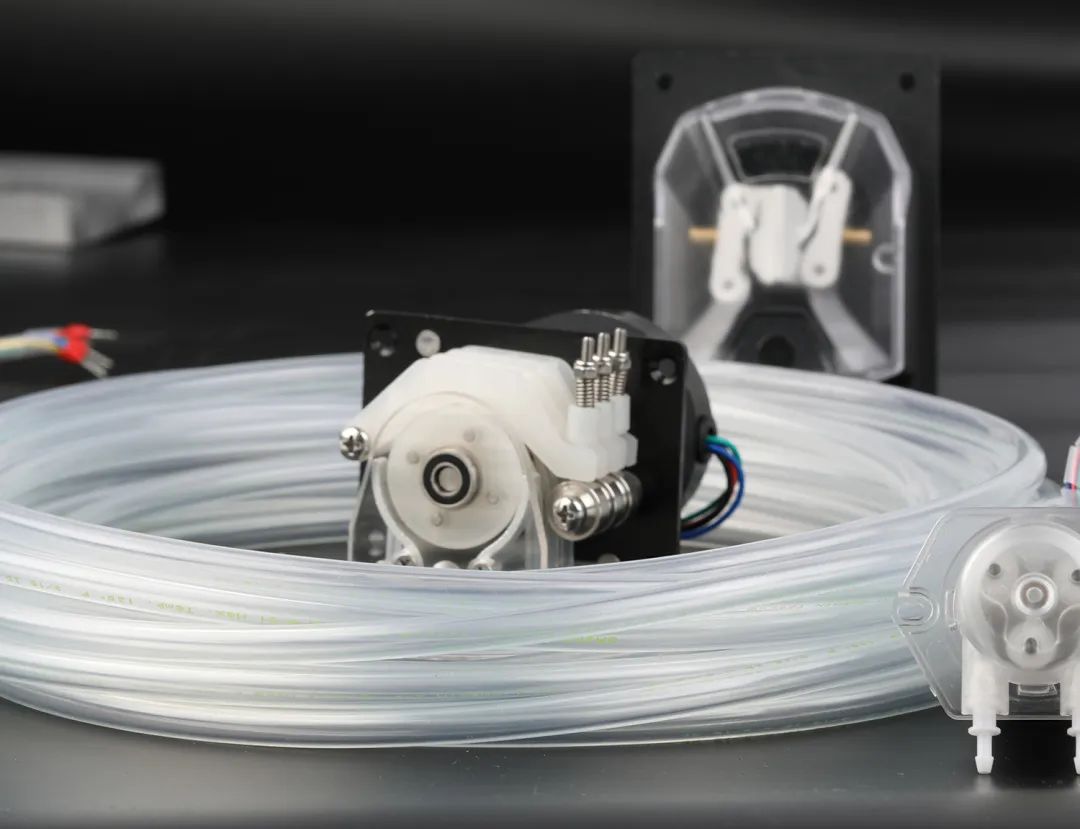

Generally speaking, the Peristaltic pump we mentioned usually includes three main parts: driver, pump head and pump tube, which together form a complete Peristaltic pump system. The driver is responsible for controlling the operating parameters of the Peristaltic pump, the pump head is responsible for generating the peristaltic effect, and the pump tube is responsible for the important task of conveying fluid. The three closely cooperate to achieve high-precision fluid transmission and control, which is widely used in laboratories, medical, chemical, environmental protection and other industries.

Today, we will discuss the important part of Peristaltic pump – pump tube, and how to start from the details, extend the service life of pump tube, and further develop the use value of Peristaltic pump.

The Importance of Pump Tubes

The pump tube undertakes the important task of transporting liquid from the pump head to the target location, and its quality directly affects the various performance of the pump: the material of the pump tube affects its corrosion resistance; Strength affects its compressive strength; The softness affects the service life of the pump; The inner diameter affects the pumping flow rate; Wall thickness affects pumping efficiency and so on.

Measures to Extend The Service Life of Pump Tubes

1.Choose the appropriate pump tube material

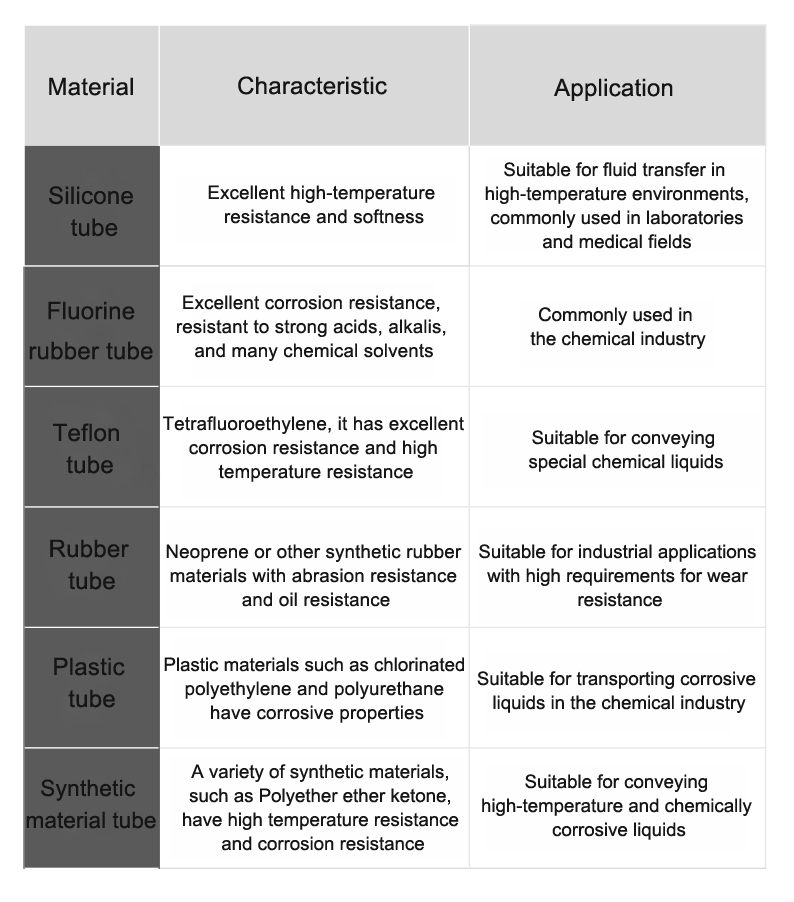

Choosing the proper pump tube material is the Committed step to extend the service life of the pump tube. When selecting, the material of the pump tube should be reasonably selected based on the specific working environment and fluid medium, to avoid exceeding its scope of use and causing unnecessary damage.

*Fluid properties

Firstly, it is necessary to understand the chemical properties of the fluid being transported. Different fluids have different requirements for pump tube materials. For corrosive fluids, corrosion-resistant materials such as fluororubber or fluorinated polymers can be selected for pump tubes. For some neutral or non corrosive fluids, ordinary silicone or PVC materials can also meet the requirements. (The chemical resistance of pump tube will decrease with the increase of temperature)

(The above is for reference only. For specific applications, please refer to the chemical compatibility table or conduct soaking experiments.)

(The above is for reference only. For specific applications, please refer to the chemical compatibility table or conduct soaking experiments.)

*Working temperature

Different pump tube materials have different temperature resistance properties. Some tubes, such as silicone rubber, have a wide temperature tolerance range and are suitable for both high and low temperature processes; Some tubes are only suitable for a small temperature range. Before selecting tubes, it is necessary to first understand the maximum and minimum temperatures in the system, and then ensure that the selected pump tube can operate within this temperature range. In applications where the temperature needs to be gradually increased, the influence of temperature on the chemical resistance and pressure bearing capacity of the pump tube should be considered (the pressure bearing capacity of the pump tube will decrease when the temperature increases).

*Fluid viscosity

Some fluids may have a certain viscosity, such as thick liquids or colloidal solutions. In this case, it is necessary to choose a pump tube suitable for high viscosity fluids to ensure smooth fluid transmission.

*Gas sensitivity of fluids

For some gas sensitive fluids, such as ttube prone to oxidation or anaerobic cell culture media, users should consider the permeability factor of the tubeline. Overall, silicone tubing has a high air permeability, so for fluids that are not suitable for contact with gas, tubes with lower air permeability should be selected.

*Photosensitivity of fluids

Firstly, it depends on whether the operator needs to observe the condition of the fluid inside the tube at any time, and also whether the fluid is sensitive to light. If the operator needs to observe the fluid, bubbles, particles, pollution, and other conditions inside the tube at any time, transparent tubes such as polyethylene or silicone tubing should be selected; If the solution is not suitable for exposure, opaque tubing should be used.

2.Correct installation

Correct installation and use are the basic guarantees for extending the service life of pump tubes. When installing the pump tube, ensure that it is not twisted or folded to avoid damage to the pump tube caused by excessive stretching or improper assembly. Pay special attention to the sealing of the pump tube connection to ensure no leakage and avoid damage caused by fluid leakage.

3.Pay attention to the fluctuation range of traffic

During the production process, attention should be paid to avoiding flow fluctuations and avoiding the use of pump tubes under high-frequency pumping. Frequent flow fluctuations may accelerate the aging and damage of the tube. Therefore, adjusting the pump speed and pressure reasonably to maintain a stable working state can help extend the lifespan of the tube.

4.Regular inspection and maintenance

Regularly checking the condition of the pump tube is an important step in extending its service life. Regularly inspect the surface of the pump tube for aging, wear, or damage. If problems are found, the pump tube should be replaced in a timely manner. At the same time, it is necessary to regularly clean the pump tube and pump head to prevent impurities from entering and causing blockage and leakage.

5.Reasonable backup of pump tubes

The spare pump tube can be quickly replaced in emergency situations to ensure uninterrupted production. Reasonable backup of pump tubes can not only cope with unexpected situations, but also reduce the pressure during emergency replacement.

6.Choose high-quality pump tube suppliers

Choose reputable and reliable pump tube suppliers to ensure that the selected pump tubes comply with relevant standards, and provide quality assurance and good after-sales service.

7.Establish pump tube usage records

Establish a record of pump tube usage, including the installation time, replacement time, and usage status of the pump tube, in order to track and manage the service life of the pump tube. By analyzing the usage records of pump tubes, potential problems can be identified in a timely manner and corresponding measures can be taken.

In the long run, the longer the service life of tubes, the lower the operating cost; The fewer times the pump tube is replaced, the lower the maintenance cost and downtime. In short, the longer the service life of the pump tube, the lower the total pumping cost. Only by keeping the pump tube in good condition, can Peristaltic pump provide more reliable and efficient fluid control solutions for experiment and production.