Milk+Lactobacillus=Yogurt

Malt+yeast=beer

Flour+yeast=bread

These common ‘magic’ in daily life.

Actually, it’s all due to biological fermentation!

Biological fermentation refers to a technology that utilizes the active in vitro enzymes of organisms (mainly microorganisms) to produce useful biological products for humans, or directly involves microorganisms in controlling certain industrial production processes. With the advancement of technology, fermentation technology is no longer limited to food manufacturing, but has expanded to a broader field, such as using genetic engineering to purposefully modify existing bacterial strains and increase production, or producing important drugs such as insulin and interferon through fermentation processes.

In fermentation technology, fermentation tanks are crucial. It creates an ideal home for microorganisms – ensuring stability in temperature, pH, and a constant supply of nutrients, as well as strict monitoring and control of the entire fermentation process. As one of the core components of the fermentation tank, the peristaltic pump ensures the accurate supply of nutrients and other important additives through precise control of flow and pressure, ensuring the stability of the entire fermentation process and the quality of the final product.

Customer Demand

Beijing XX Technology Co., Ltd. focuses on the research and development and production of biological fermentation, biological separation, and environmental engineering equipment, with products covering biological fermentation tanks, purification columns, etc. To meet the new needs of microbiology laboratories, it is necessary to develop a high-precision fermentation tank. To ensure the optimal growth conditions of microorganisms, the company is looking for a high-performance peristaltic pump to ensure a continuous and stable supply of nutrients and other additives.

Key technical challenges:

- Liquid supply: Provide 4 continuous liquid supplies, including nutrient solution, acid alkali solvent for pH regulation, and defoamer

- Sterility requirements: The entire conveying system must be sterile to prevent external contamination of microorganisms

- Specification of peristaltic pump: meet the flow control of ≤ 100mL per minute, and ensure that the conveying accuracy error is within ± 5%

Lead Fluid Solution

In order to meet the technical requirements of customers, the Leifu team has conducted detailed research and evaluation, combined with the key points of process control in the fermentation field, and considering the specific application scenarios in the laboratory, four fixed speed peristaltic pumps have been configured for each reactor, which use KT15 pump heads and AC synchronous motors, embedded in the control panel of the fermentation tank.

In specific applications:

The first route is mainly aimed at stable supply of nutrients

The next two routes are used for precise pH control

And the fourth route is responsible for adding defoamers

This technical configuration ensures continuous nutrient supply, pH stability, and effectively controls bubble generation, creating an ideal growth environment for microorganisms.

OEM Product KT15

Product Introduction

Pump Head Material

Roller: PVDF

Body: PPS

Pump head cover: PC

Spring: SS304

Tube clamp: PVDF

Tube connector: PP/PTFE

Pump Head Specifications

Channel: 1

Roller: 2

Tubing method: The whole tube /tube connector(tube ID more than 1.0mm)

Tube clearance: Can be fine-tuned

Weight: 150g

Motor: Stepper motor,AC motor,DC reduction motor, AC reduction motor

Excellent chemical corrosion resistance

The main body of the pump head is made of PPS material, and the roller body is made of PVDF material, which has excellent mechanical properties and excellent chemical corrosion resistance

Accurate and stable traffic

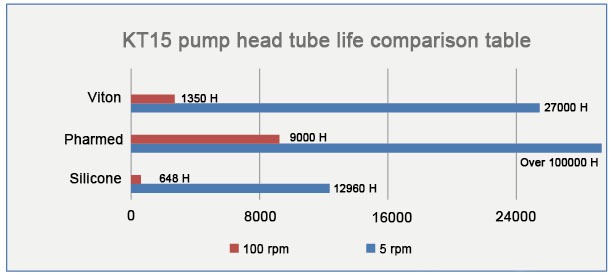

The KT15 pump head roller body adopts a classic elastic fixed structure, which can provide accurate and stable flow rate and excellent tube life

Pressure tube gap can be adjusted slightly

The pressure tube gap can be adjusted to adapt to different wall thicknesses and output greater pressure

Wide flow range

By selecting tubes with different inner diameters, the flow range can reach 4-630mL per minute

Clean and pollution-free

During the transmission process of KT15, the liquid only comes into contact with the hose and will not cause any pollution to the pump head or liquid. Its low shear design can maintain the activity of the culture medium without damage.

Given that fermentation tanks in the laboratory often require different types of liquids to be replaced, KT15 can quickly adapt to different transmission needs by simply replacing tubes.

Date Display

Customer Reviews

The person in charge of the procurement department gave high praise to the Lead Fluid products. They believe that Lead Fluid peristaltic pump is very suitable for matching in fermentation tanks, and the customer’s feedback is also very good. They have stated that they will continue to cooperate with Lead Fluid to jointly promote the development of fermentation processes.