Introduction

As a precision fluid transfer device, peristaltic pumps are widely used in chemical, pharmaceutical, food processing, and environmental protection industries. The tubing, being one of the core components of peristaltic pumps, has its acid and alkali resistance directly determining the pump’s service life and the safety of fluid transfer. This article will thoroughly examine the performance characteristics of peristaltic pump tubing in different acid and alkali environments, providing reference for engineers to select appropriate tubing materials.

-

Overview of Peristaltic Pump Tubing Materials

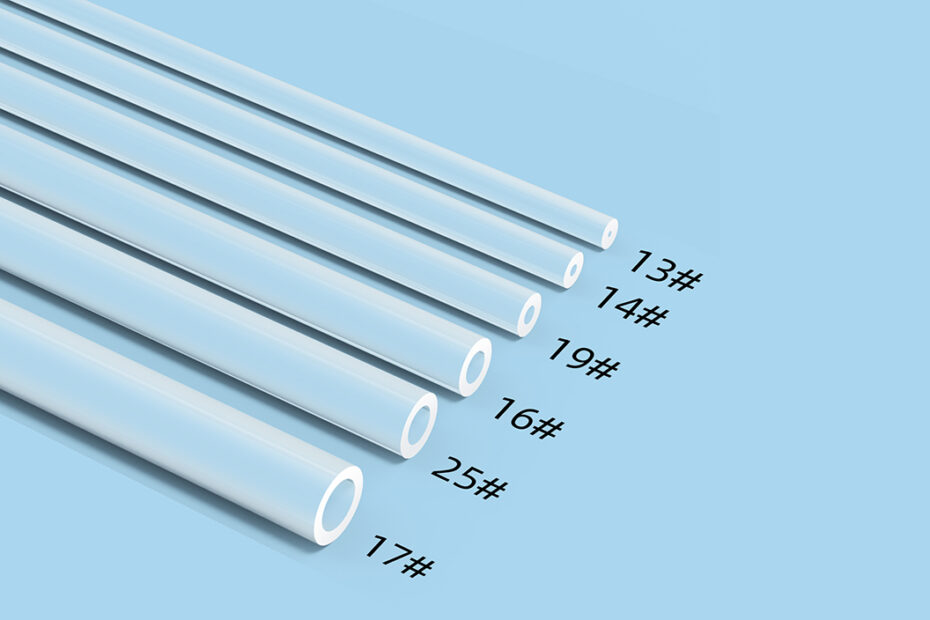

Peristaltic pump tubing is mainly categorized into the following types based on material:

Silicone Tubing: Offers excellent flexibility and biocompatibility with a wide temperature range

FKM (Fluorocarbon Rubber) Tubing: Superior chemical corrosion resistance, especially suitable for strong acid and alkali environments

Polyurethane Tubing: High wear resistance with moderate chemical resistance

PVC Tubing: Low cost, suitable for weak acid and alkali environments

EPDM (Ethylene Propylene Diene Monomer) Rubber Tubing: Outstanding oxidation and weather resistance

Each material demonstrates significantly different resistance to acids and alkalis due to variations in molecular structure. Understanding these differences is crucial for proper selection.

-

Tubing Performance in Different pH Environments

Strong Acidic Environments (pH<3)

Tubing materials face severe challenges in strong acidic environments:

FKM Tubing: Performs best, resistant to concentrated sulfuric acid (98%), hydrochloric acid (37%), etc., with long-term service temperature up to 200°C

Silicone Tubing: Good resistance to medium-low concentration inorganic acids (e.g., 10% sulfuric acid) but corroded by hydrofluoric acid

Polyurethane Tubing: Only suitable for weak acidic environments as strong acids cause material hydrolysis degradation

PVC Tubing: Rapidly damaged by strong oxidizing acids like concentrated sulfuric and nitric acids

Case Study: A chemical plant transporting 30% hydrochloric acid solution found that standard silicone tubing lasted only 2 weeks, while switching to FKM tubing extended service life to over 6 months.

Weak Acidic Environments (pH 3-6)

Most tubing materials perform well in this range:

Silicone Tubing: The most common choice, excellent resistance to organic acids (e.g., acetic acid, citric acid)

Polyurethane Tubing: Suitable for acidic food and beverage transfer, compliant with FDA standards

EPDM Rubber: Unique resistance to oxidizing acids (e.g., hypochlorous acid)

Neutral Environments (pH 6-8)

Nearly all tubing materials are suitable for neutral environments:

PVC Tubing: The most cost-effective option

Silicone Tubing: Ideal for high-purity applications like pharmaceutical industry

Polyurethane Tubing: Excellent choice for high-pressure transfer

Weak Alkaline Environments (pH 8-11)

Silicone Tubing: Performs well but shows slight swelling with prolonged exposure

Polyurethane Tubing: Resistant to most weak alkalis but degrades faster with amine compounds

EPDM Rubber: Good resistance to alkaline cleaners

Strong Alkaline Environments (pH>11)

Strong alkalis are extremely destructive to tubing materials:

FKM Tubing: The only material that can long-term withstand concentrated sodium hydroxide (50%)

Silicone Tubing: Gradually corroded by strong alkalis, leading to surface powdering

PVC Tubing: Rapidly becomes brittle and cracks in hot, strong alkaline solutions

Application Example: In sodium hydroxide solution transfer systems, FKM tubing lasts over 10 times longer than standard rubber tubing.

-

Other Factors Affecting Tubing Acid/Alkali Resistance

Temperature Impact: Chemical corrosion rate approximately doubles with every 10°C temperature increase

Pressure Factors: High pressure accelerates chemical penetration through tube walls

Mechanical Stress: Peristaltic pump compression action intensifies chemical corrosion

Exposure Duration: Long-term immersion causes different corrosion levels than intermittent contact

Concentration Gradient: Generally, higher concentrations increase corrosiveness

-

Tubing Selection Recommendations

Comprehensive Fluid Analysis: Including pH value, chemical composition, concentration, temperature, etc.

Operational Parameters: Flow rate, pressure, pump speed, and other operating conditions

Certification Requirements: Industry standards like FDA, USP Class VI

Cost-Benefit Analysis: Balancing initial cost with service life

Field Testing: Conducting long-term tests in small-scale systems

-

Maintenance and Replacement Guidelines

Regular Inspection: Check for discoloration, swelling, cracks, or surface roughness

Preventive Replacement: Establish replacement schedules based on operating hours

Proper Storage: Avoid direct sunlight and extreme temperatures

System Cleaning: Flush with neutral solutions during shutdowns

Conclusion

Selecting peristaltic pump tubing with appropriate acid/alkali resistance is an engineering technology requiring comprehensive consideration of multiple factors. Proper selection not only extends tubing service life and reduces maintenance costs but also ensures process stability and product quality consistency. With advancements in materials science, future high-performance tubing capable of withstanding extreme chemical environments will provide more reliable fluid transfer solutions across industrial sectors.