Solving the three major challenges of pharmaceutical filling with ease!

● Expensive raw materials, precision hard to guarantee.

● Equipment limitations, frequent leakage.

● Complicated tube loading, low production efficiency.

DMD15 – Tailored for high-precision, small-volume filling needs

[Precise Filling, Cost-Effective]

Minimum filling volume: 200µL, with a filling accuracy of 200µL ±3µL. Compact size, attractive design, easy operation, and stable, reliable performance provide you with an economic and efficient filling solution.

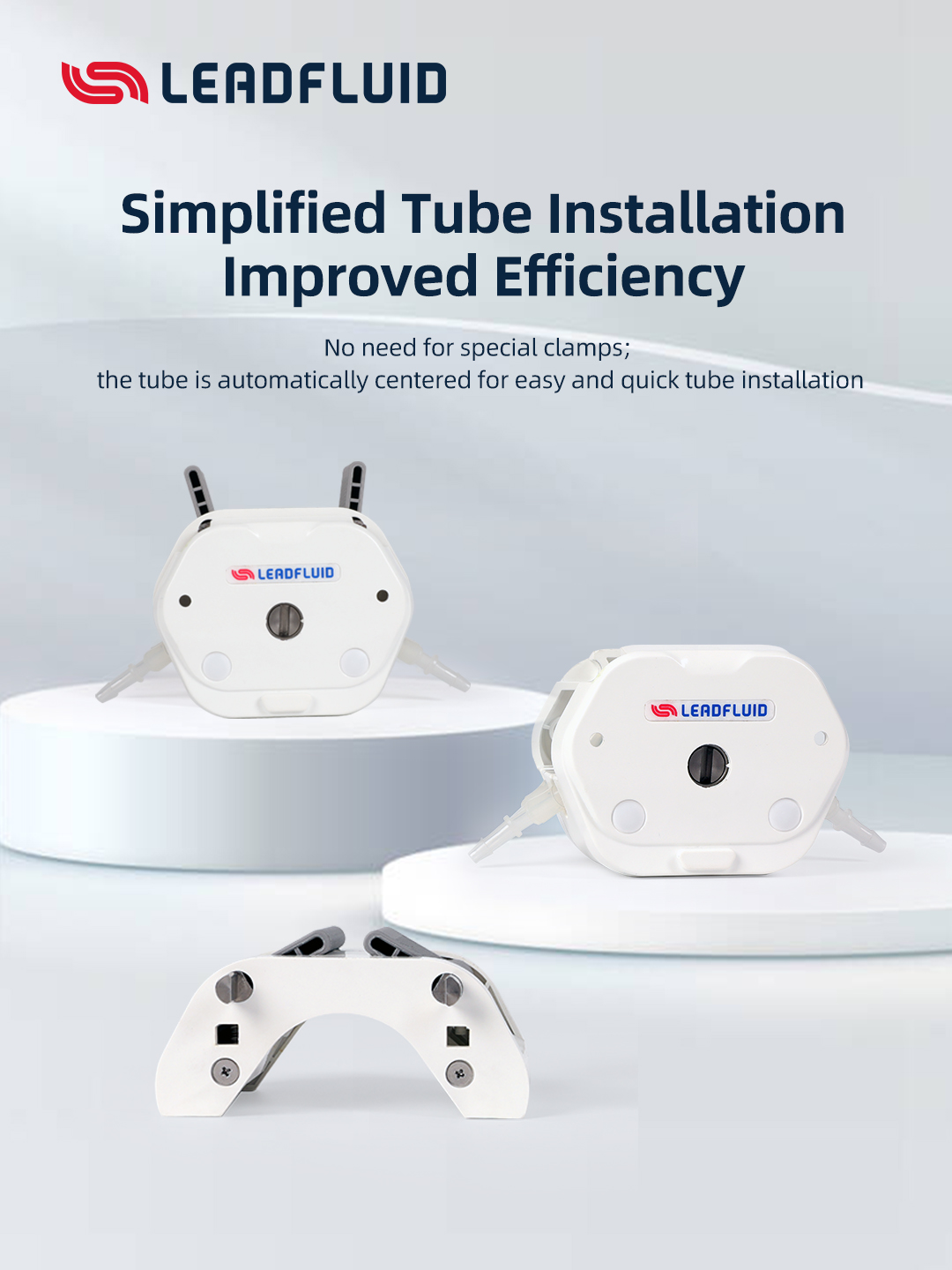

[Simplified Tube Loading, Efficiency Upgrade]

Specially designed tube fittings require no special tube clamps. The tube automatically centers, making quick and easy tube loading possible.

[Elastic Pressure Block for Versatility]

The elastic pressure block design effectively reduces leakage risk, enhances stability, and extends tube life. Compatible with a variety of tube sizes to meet different needs.

[Compact and Comfortable Operation]

Non-slip textured dual-lever handle for one-handed operation. Secure grip and comfortable feel.  [Low Pulsation, High Precision]

[Low Pulsation, High Precision]

Roller-phase compensation technology effectively reduces pulsation, improving filling accuracy and stability.

[Upgraded Safety Features]

Optional cover-open stop-pump function for enhanced operational safety.

Come and experience the Lead Fluid DMD15 pump head, and start a new chapter in high-precision micro-filling!