A peristaltic pump is a specialized type of pump commonly used in industrial and laboratory applications, with its unique working principle and performance making it widely applied in many fields. This article will introduce the working principle, application areas, and advantages of peristaltic pumps.

Working Principle

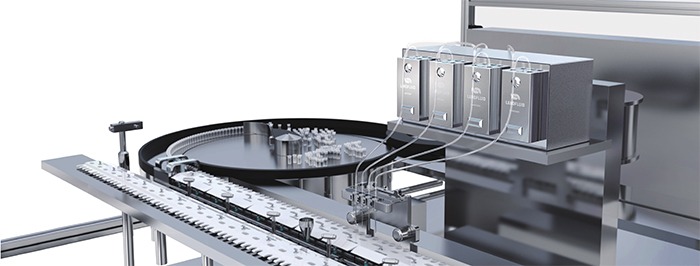

A peristaltic pump, also known as a hose pump or tube pump, generates fluid pressure for transport by compressing a flexible hose or tubing. Its operation is based on peristaltic motion, which involves pushing fluid or gas through compression and relaxation of a flexible tube or hose. Typically, a peristaltic pump consists of a flexible tube or hose compressed by a series of rollers or pressure elements, thereby propelling fluid forward or drawing it in.

Application Areas

Chemical Industry: Peristaltic pumps are valuable for chemical transport and mixing processes, handling various corrosive or viscous fluids with ease.

Pharmaceutical Industry: In pharmaceutical processes, peristaltic pumps are used to precisely deliver drugs or biologics due to their non-contaminating nature.

Food and Beverage Industry: These pumps are employed to transport various food ingredients such as berries, jams, sauces, etc., owing to their material-friendly and hygienic standards.

Environmental Engineering: Used for wastewater treatment, sludge handling, chemical dosing, and other environmental engineering applications.

Medical Applications: In medical devices, peristaltic pumps are utilized for drug delivery, artificial respiration devices, and more.

Advantages

High Reliability: Simple construction with no valves or mechanical seals, resulting in low failure rates.

Versatility: Capable of transporting various types of liquids, including high-viscosity fluids and fluids containing solid particles.

Ease of Maintenance: Simple maintenance requiring only periodic replacement of the hose or tubing, without the need for lubrication or special care.

Minimal Contamination: Ensures fluid integrity without external contamination, making it ideal for industries with stringent hygiene standards.

Conclusion

Peristaltic pumps are widely applied in various industries due to their unique working principle and superior performance. With advancing industrial technology and increasing demand for efficient and reliable transport, the application prospects of peristaltic pumps will continue to expand and deepen, bringing more convenience and benefits to industrial and research sectors.