How to Choose Peristaltic Pump Tubes?

Peristaltic pump tubes are an important component of peristaltic pumps. How to choose tubes is also a knowledge in peristaltic pump procurement. Let’s explore how to choose peristaltic pump tubes together?

1. Chemical compatibility

The tube needs to have chemical compatibility with the pumped fluid in order to have good pumping performance and safety performance. Chemical compatibility refers to the certain chemical properties exhibited by tubes when transporting different fluids, which is called chemical compatibility. For example, low adsorption, good temperature resistance, less prone to aging, no swelling, corrosion resistance, low precipitation, etc.

2. Under pressure

The application of peristaltic pumps is limited by the pressure bearing performance of tubes. If the system pressure exceeds the limit pressure of the tube, the tube will expand, causing excessive wear or rupture of the tube. The factors that affect the pressure of tubes include: material, ratio of diameter to wall thickness, etc.

3. Dimensions

The size of the tube directly affects the flow rate, and the inner diameter of the tube determines the flow rate, which is directly proportional to the flow rate. The wall thickness affects the ability of the tube to be compressed and rebound, and also has a significant impact on the lifespan of the tube.

4. Temperature

Different materials have different temperature performance, and some tubes such as silicone rubber have a wide temperature tolerance range, which is suitable for both high and low temperature processes; And some tubes are only suitable for a small temperature range. Before selecting tubes, end users should first understand the maximum and minimum temperatures in the system, and then ensure that the selected tubes work safely within this temperature range.

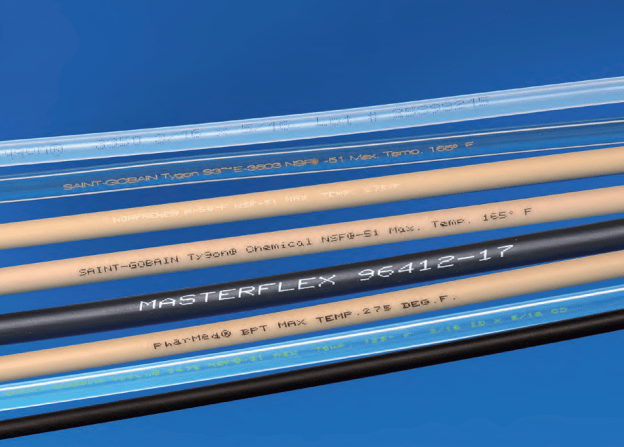

5. Transparency

Whether a transparent tubeline should be used depends first on whether the operator needs to observe the condition of the fluid inside the tubeline at any time, and also on whether the fluid is sensitive to light. If the operator needs to observe the fluid, bubbles, particles, pollution, and other conditions inside the tube at any time, transparent tubes such as Tygon polyethylene or silicone rubber should be selected; If the solution is not suitable for exposure, opaque tubing should be used.

6. Breathability

For some gas sensitive fluids, such as those prone to oxidation or anaerobic cell culture media, users should consider the permeability factor of the tube. For fluids that are not suitable for contact with gases, tubes with lower air permeability should be selected, such as Phamed ® BPT tube, NORPRENEA-60-F tube, etc.