Selection of Peristaltic pump is the first step when purchasing Peristaltic pump

Do you know how to select Peristaltic pump? Let’s learn together.

Q1 Determine the Application Requirements

To select a suitable Peristaltic pump, first determine the application requirements:

1.Determine traffic size

2.What kind of liquid needs to be transported

3.Requirements for accuracy

4.Number of channels required

5.Pressure range, control method, etc

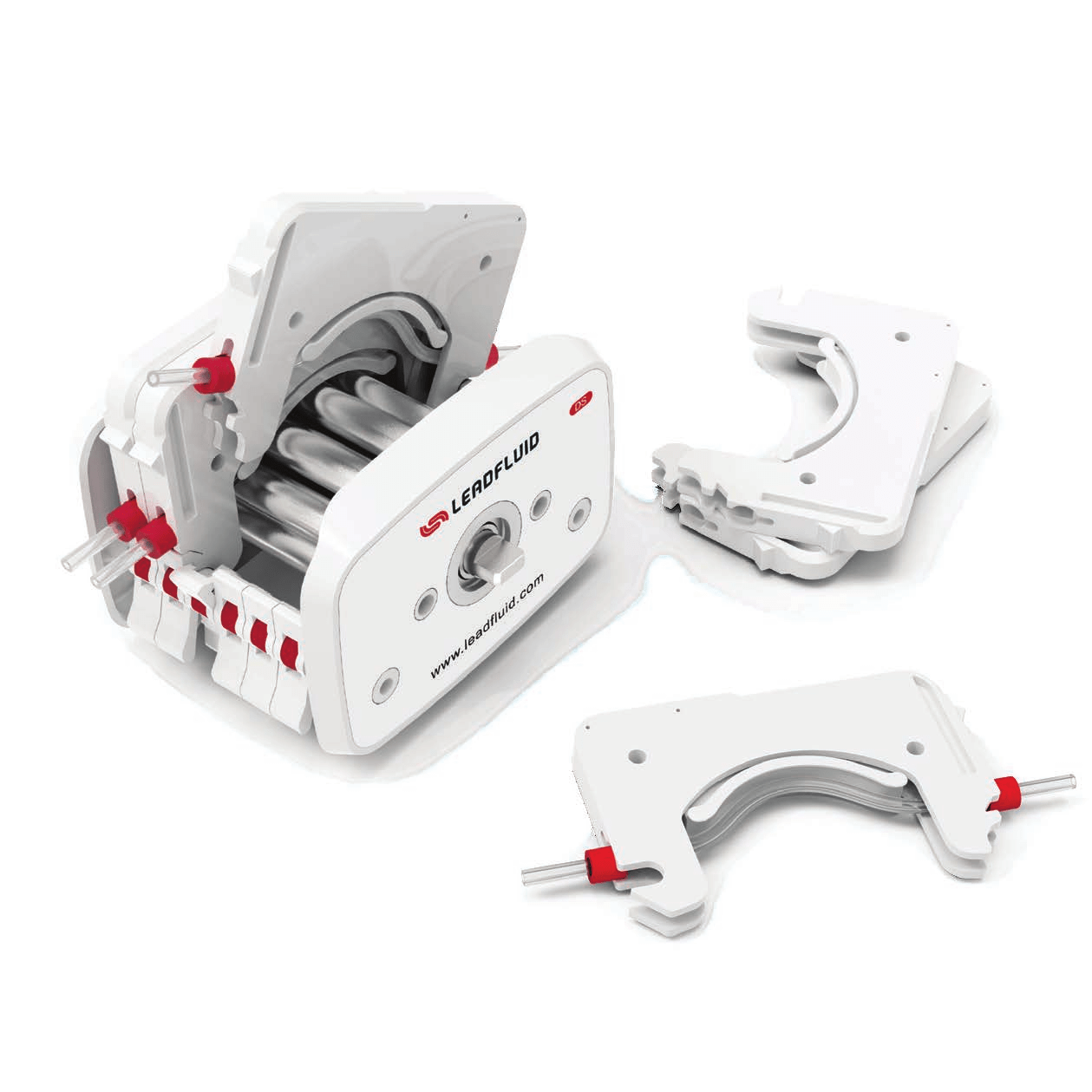

The Peristaltic pump is mainly divided into three parts: pump head, tube and driver. Next, we will select the corresponding performance parameters of these components according to the needs.

The second step is to select the pump head, tube, and driver. How should these components be selected?

Q2 Pump Head Selection Guide

In many applications, the selection of pump heads is crucial. The correct use of the pump head can eliminate many unnecessary faults during startup and operation. The following are the factors to consider when selecting the pump head function:

1.Flow rate: Different pump heads can achieve different flow rates.

2.Number of rollers: The number of rollers is a key factor determining the size of pulsation, and the requirements for pulsation determine the number of rollers.

3.Required number of channels: In most cases, the pump head can be stacked.

4.Pump head material: depending on the type of transmission medium, if the medium contains organic solvents and Corrosive substance, the pump head with appropriate material shall be selected.

Q3 Tube Selection Guide

Choosing the appropriate pump tube is equally important as selecting the pump head. A good pump tube should have excellent characteristics.

1.Chemical compatibility: Choose tube based on the liquid. If the liquid contains corrosive substances, choose tube with strong corrosion resistance.

2.Inner diameter and tube wall hardness: The size of the inner diameter is proportional to the flow rate; The hardness of the tube wall is crucial for determining the pumping capacity of a specific tube line. If the pump tube is too soft, it is easy to be damaged; If the pump tube is too hard, the pump cannot operate.

3.Service life of pump tube: If the tube is used for a long time, it may break due to wear and tear, leading to fluid overflow, which may cause harm to human body or equipment. Therefore, the condition of the tube should be checked frequently and replaced in a timely manner.

Q3 Pump Drive Selection Guide

1.Speed: The speed of the driver is directly related to the flow rate.

2.Accuracy: depends on the speed control accuracy.

3.Material: If the working environment contains Corrosive substance, the driver with corrosion resistance shall be selected.

4.Protection level: If the working environment requires waterproofing and dust prevention, drivers with appropriate IP levels should be selected.

Welcome to connect with Lead Fluid company for more details.