Peristaltic pump is widely used in the matching of graphite digestion instrument. How do they cooperate? Let’s explore together.

A company is a scientific and technological innovation enterprise integrating scientific research, production, sales and maintenance. With spectrum technology as the core, it mainly deals in the pretreatment equipment and professional technical services related to the turntable electrode atomic emission spectrometer and other spectral instruments.

The company has been focusing on the research and development of spectral instruments for nearly 40 years. It has a group of professionals who have been engaged in the research and development of analytical instruments, instrument production and analytical applications for a long time. It has a deep problem solving ability, takes meeting the changing customer needs of the market as its own responsibility, and strives to create high-quality products and services.

Problems to be solved

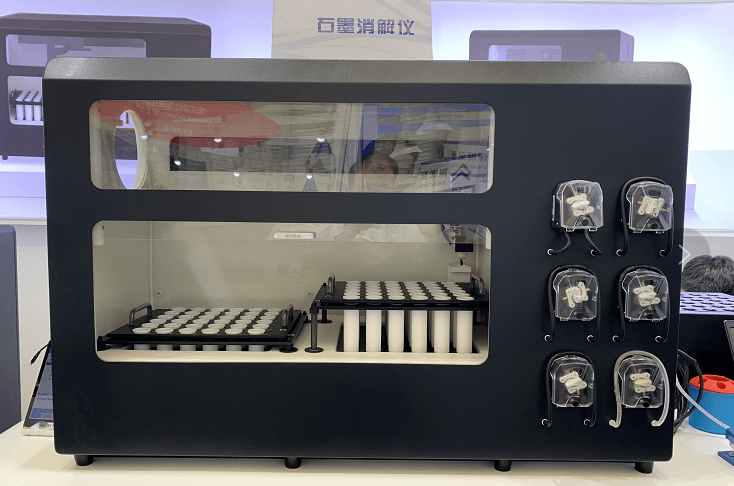

The laboratory is the cradle of science. In scientific research experiments, special personnel are required to handle sample digestion steps. In order to further improve scientific research efficiency and digest experimental samples more quickly, the company introduced a graphite digestion instrument.

The graphite digestion instrument uses high-purity graphite material as the heating body, mainly used in the pretreatment of laboratory sample digestion, heating and acid removal in the environment, food, research and development, project production, etc. The processed samples enter the atomic fluorescence spectrometer and other analytical instruments for sample analysis and detection. The appearance of graphite digestion instrument has effectively improved the experimental efficiency.

Graphite digestion apparatus needs to use various acids for sample processing, such as hydrochloric acid, nitric acid, etc. Most acids are volatile and harmful to human health. Therefore, to ensure the safety of such strong corrosive fluid in transmission is the pain point that needs to be solved urgently for the graphite digestion instrument.

Graphite digestion apparatus needs to use various acids for sample processing, such as hydrochloric acid, nitric acid, etc. Most acids are volatile and harmful to human health. Therefore, to ensure the safety of such strong corrosive fluid in transmission is the pain point that needs to be solved urgently for the graphite digestion instrument.

Peristaltic pump ensures the safety of fluid transmission

Lead Fluid peristaltic pump is made of PPS material with excellent mechanical performance and excellent chemical corrosion resistance, which can perfectly solve this pain point. When peristaltic pump is used for fluid transmission, it adopts strong corrosion resistant hose, which can easily transmit strong acid and other fluids.

The enclosed environment of the pump pipe can effectively avoid the volatilization of acidic substances and ensure the life safety of laboratory users. The Lead Fluid peristaltic pump is made of translucent plastic, which can observe the internal operation of the pump head at any time, and effectively prevent external debris from entering the pump head, so that laboratory operators can observe the working conditions at any time and reduce maintenance costs.

The Lead Fluid peristaltic pump is made of translucent plastic, which can observe the internal operation of the pump head at any time, and effectively prevent external debris from entering the pump head, so that laboratory operators can observe the working conditions at any time and reduce maintenance costs.

The Lead Fluid peristaltic pump can provide accurate, stable and adjustable flow, which can meet the needs of continuous transmission and quantitative transmission of various changes in the laboratory, fully improve the experimental efficiency, and save time and cost.

The person in charge of the equipment department of the company said:

Since the graphite digestion instrument is equipped with a Lead Fluid peristaltic pump, it is more reassuring to transmit fluid without worrying about the direct damage of corrosive liquid to the instrument, effectively increasing the corrosion resistance and service life of the instrument.

In the terminal application, it has reduced the maintenance cost, won the praise of customers, and improved the reputation of our products. Lead Fluid has become a long-term partner of our company.