In the context of covid-19, the market scale of in vitro diagnostics has grown rapidly, and the demand for in vitro diagnostic reagents has risen sharply. Production capacity, efficiency and quality have become the triple test facing relevant enterprises. Whoever can take the lead in solving the problem can seize the first advantage in the fierce market competition.Peristaltic pump plays an important role in the in vitro diagnostic reagent industry.

Customer profile

A well-known biological company is a national high-tech enterprise integrating R & D, production, sales and technical services of genetic diagnosis reagents, supporting testing instruments and other products. Its main products include nucleic acid extraction reagents, cervical cancer detection reagents, biological and genetic detection reagents and so on. It has won the title of “top ten advanced reagents” in Chinese laboratory medicine. Relying on independent innovation, the company has successfully developed a practical gene chip diagnostic technology platform, taking the lead in realizing the industrialization of gene chip technology in China. In 2021, the company has a new demand: filling 8 different media liquids at the same time, including protease, magnetic beads, glycerol and other liquids, and the filling volume has increased from 20 μ l-1000 μ L each channel is unequal.

In 2021, the company has a new demand: filling 8 different media liquids at the same time, including protease, magnetic beads, glycerol and other liquids, and the filling volume has increased from 20 μ l-1000 μ L each channel is unequal.

In the face of the new market demand, the company has tested a variety of filling pumps, such as ceramic piston pumps, stainless steel piston pumps, piston pumps and linear peristaltic pumps. None of these pumps can fully solve the problems of magnetic bead adsorption, liquid hanging, calibration trouble, low efficiency and poor repeatability generated in the filling process. Therefore, the company is eager to find a transfer pump that can meet the requirements.

Filling volume coverage to micro upgrade

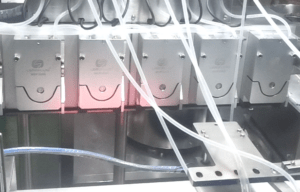

Lead Fluid WSP3000 microliter peristaltic pump is available on demand. The microliter peristaltic pump is suitable for high-precision filling of various aqueous solutions, and the filling liquid volume can cover 1-3000 μL. The filling accuracy is up to 0.2%, and the filling efficiency of a single channel is up to 120 bottles / min. It has the dual advantages of high precision and high efficiency, which can help the company improve work efficiency, save material costs, and further promote production capacity.

Lead Fluid WSP3000 microliter peristaltic pump is simple to operate, and liquid volume parameters can be directly input on the human-machine interface, thus reducing the operation cost and greatly improving the experience of operators. Modular design, easy to expand, can be cascaded according to filling requirements.

Lead Fluid WSP3000 also has the advantage of low maintenance cost. Compared with ordinary peristaltic pumps, the pump tube loss is smaller, the loading attenuation of the hose is less than 1% after 12 hours of continuous operation, and the service life can reach 1000 hours.

The application of Lead Fluid WSP3000 microliter peristaltic pump has improved the filling accuracy and work efficiency, and has performed well before the triple test of productivity, efficiency and quality.

The person in charge of the company’s production workshop said:

Since the filling equipment was equipped with the Lead Fluid microliter peristaltic pump, the work efficiency has been effectively improved, the order delivery rate has been guaranteed, and the production capacity has been rising. The excellent performance of the Lead Fluid microliter peristaltic pump has surprised us and renewed our impression of the domestic peristaltic pump.

At the same time, because of the high-precision characteristics of the Lead Fluid microliter peristaltic pump, waste is avoided in filling. The maintenance cost of the Lead Fluid WSP3000 microliter peristaltic pump is also very low, which fully saves the labor cost, time cost and material cost. The Lead Fluid WSP3000 microliter peristaltic pump will be our long-term choice.