As we all know, peristaltic pump is composed by three parts: the peristaltic pump motor, the peristaltic pump tube and the peristaltic pump head. Have you ever had motor selection difficulties when choosing the peristaltic pump? Let’s talk about the difference about different motors.

What are the common motors of peristaltic pump?

For standard peristaltic pumps and OEM peristaltic pumps, the commonly used motors are DC motor, AC motor and stepper motor.

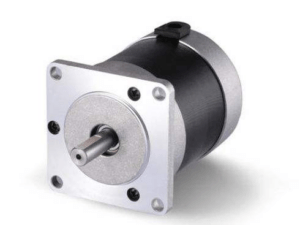

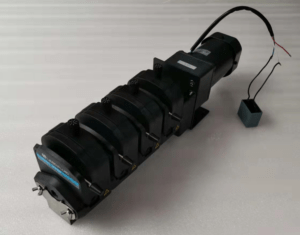

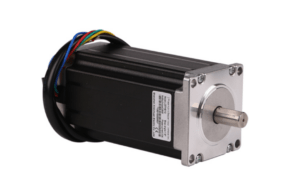

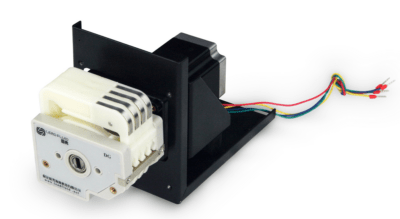

For example, the peristaltic pump BT600F is stepper motor, the OEM peristaltic pump MC10 series is DC motor and the OEM pumps KZ25 series is AC motor, just like the pictures below :

What are the characteristics of different motors?

DC motor refers to the rotating motor that can convert DC electric energy into mechanical energy, or convert mechanical energy into DC electric energy. It is a motor that can realize the mutual conversion of DC energy and mechanical energy.

DC brushless motor and DC brushless motor are commonly used in peristaltic pump. The difference between DC brush motor and brushless motor is whether brush commutator is equipped (hereinafter referred to as brush motor and brushless motor).

Brush motor

The brush motor is very simple to use and control. Its advantages are: excellent low-speed torque performance, large torque, high precision, stable starting and braking, and stable operation at constant speed. The disadvantage is that the structure is complex, the maintenance workload is heavy, and the brush needs to be replaced constantly.

Brushless motor

Brushless motor is a typical mechatronics product, which is composed of motor body and driver. Brushless motor has the advantages of low sound, low noise, no spark, suitable for flammable and explosive scenes, and long service life. The disadvantage is that the cost is high, and it is not suitable for application in high magnetic field areas.

2. AC motor

AC motor is a motor that can realize the mutual conversion of mechanical energy and AC energy.

The AC motor has the advantages of simple structure, convenient manufacture, easy maintenance and low environmental requirements. The power covers a wide range, ranging from a few watts, dozens of watts and even millions of kilowatts. The disadvantage is that the startup and speed regulation are poor.

3. stepper motor

Stepper motor is a kind of motor that converts electric pulse signal into corresponding angular displacement or linear displacement. Every time a pulse signal is input, the rotor rotates an angle or advances one step. The output angular displacement or linear displacement is directly proportional to the number of input pulses, and the speed is directly proportional to the pulse frequency. Therefore, stepper motor is also called pulse motor.

Stepper motor has excellent start stop and reverse response, large output torque, high precision,small volume and good control performance. The disadvantage is that if it is not properly controlled, it is easy to produce resonance and vibration and noise when working at high speed.

Lead Fluid peristaltic pumps equipped with these motors have been widely used in medical testing equipment, laboratory testing instruments, pharmaceutical equipment, environmental protection online monitoring instruments, agricultural drip irrigation systems, food machinery and other industries. Surround yourself and make their contribution silently.

More questions,welcome to connect us any time~