Filling Peristaltic Pump Working Principle

The filling peristaltic pump machine is composed of a filling system consisting of a main drive system, a bottle feeding system, a group of pump heads and a filling dispensing system, a plugging system consisting of a plug supply group and a plugging group, and an electrical control system. The structure is novel and reasonable. The peristaltic pump filling system transports the liquid by peristalizing the hose through the rotating roller. The liquid to be conveyed only flows in the hose and does not contact with other parts of the pump, thus avoiding the contamination of the liquid by the pump body.

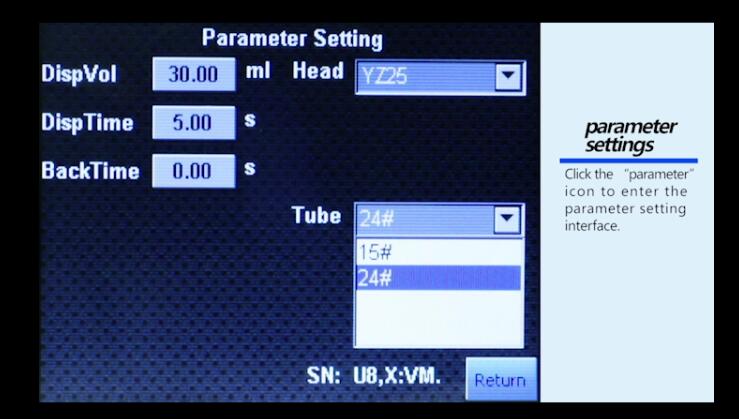

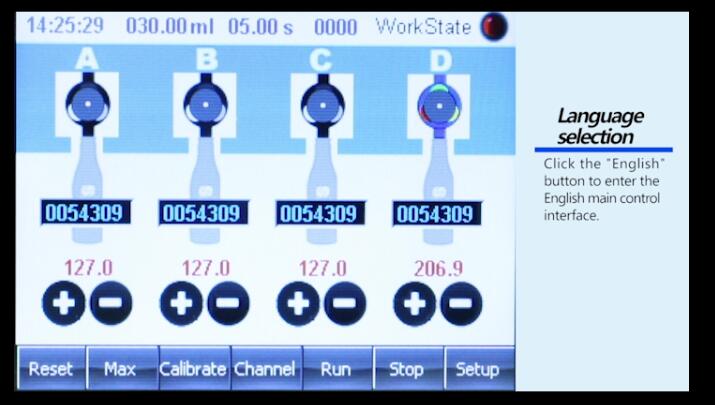

The filling peristaltic pump is the pump with the highest technical content among the various styles of peristaltic pumps, in terms of pump design and its own performance. The filling peristaltic pump machine makes full use of the characteristics of the peristaltic pump, the structure is simple, and the pump body has no contact with the liquid, so there is no need to clean and disinfect the pump body. The pump is driven by a stepping motor or a servo motor. The PLC control makes it easy to adjust the loading capacity. Just input the corresponding number. It can be adjusted at any time under the working state, and the accuracy error can reach ±1%. The modular structure is adopted.

What are the advantages of using peristaltic pump?

Small in appearance, it can be placed anywhere.

The intelligent operation interface is very convenient to use.

Flexible filling.

High filling accuracy.

Solve filling problems (liquid hanging, dripping, splashing, etc.).

It can be matched with the production line to follow the filling.

Long service life.

What are the function of Lead Fluid filling system?

Peristaltic pump fillers application

|

|

Suitable for filling most types of liquids, including high viscosity liquids. Such as: various pharmaceuticals, chemicals, oils, cosmetics, food and other non-granular liquids; high filling accuracy, suitable for laboratories and industrial occasions, can be automatically matched with filling production lines.