Deuterated Acids/Bases at “Sky-High” Prices (¥1,000/gram)

Production Costs Slashed by 80%!

Recently, the Precision Intelligent Chemistry National Key Laboratory at the University of Science and Technology of China (USTC) published groundbreaking research in Nature: For the first time, green, low-cost production of deuterated acids and bases was achieved using bipolar membrane water dissociation technology.

In this innovative experiment, Lead Fluid’s BT600L peristaltic pump ensured safe and reliable fluid circulation with its precision flow control. At this historic moment, we stand alongside innovation!

China University of Science and Technology Achieves Major Breakthrough in the Preparation of Deuterated Acid-Base Chemicals

(Image source: Anhui News Broadcast, China)

01 Deuterated Acids/Bases Enter a Low-Cost, Green Era

Deuterated acids and bases are key raw materials for synthesizing deuterated drugs, conducting hydrogen/deuterium exchange, and extending the lifespan of OLED devices. However, the long-standing production of these chemicals has heavily relied on high temperature and pressure, strongly corrosive chemicals, and heavy metal catalysts, resulting in high production costs and severe environmental pollution, making large-scale, green production difficult to achieve.

Today, the University of Science and Technology of China has “made history” with their “one-step” process:

Heavy water + inorganic salts → Bipolar Membrane Electrodialysis Technology → High-purity deuterated acids and bases.

The entire process is completed at room temperature, without the need for strongly corrosive reagents or heavy metal catalysts, resulting in almost zero emissions!

02 BT600L: A Reliable Partner in Scientific Research

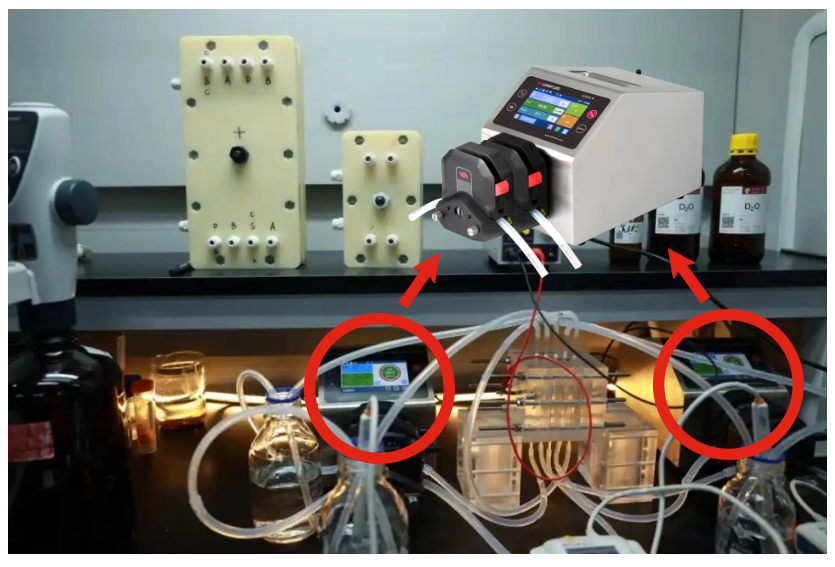

Bipolar Membrane Heavy Water Dissociation Experimental Setup

(Original image sourced from Voice of Chinese Academy of Sciences)

The core of the experimental setup is a bipolar membrane electrodialysis system, whose stable operation depends on three critical fluid-handling properties:

Fluid Isolation

Different solution loops (acid, base, salt) remain fully independent to prevent cross-contamination—ensuring product purity.

Precise & Controllable Flow Rates

Each circuit’s flow must be precise and stable to ensure effective circulation of the solution within the membrane stack. This is crucial for maintaining an appropriate concentration gradient at the membrane interface, preventing local concentration imbalances (which can lead to reduced efficiency or membrane fouling), and enhancing hydrolysis and ion migration efficiency.

Easy Cleaning & Corrosion Resistance

The conveying equipment must be resistant to acid and alkali corrosion, have a simple structure for thorough cleaning, and allow for quick replacement of components.

03 BT600L’s Core Advantages

Functional Features:

Contamination-Free Design

Liquid contacts only disposable tubing, eliminating cross-contamination risks.

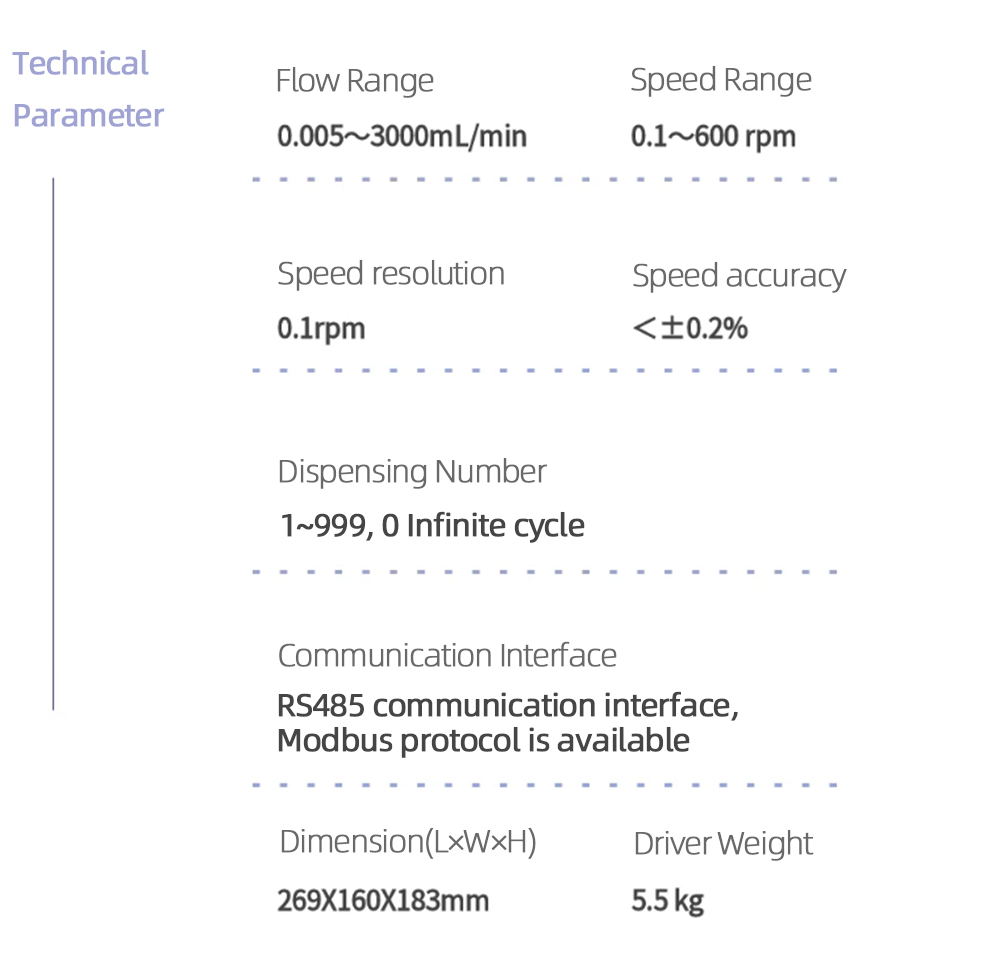

Precision Flow Control

±0.2% high-precision control combined with micro-stepping algorithm ensures stable flow rate through the membrane stack.

With an adjustable flow range of 0.005-3000 mL/min, this setup prevents local concentration imbalances and enhances hydrolysis efficiency and product consistency.

Leak-Resistant & Corrosion-Proof

The back suction function reduces the risk of drips. The stainless steel housing is acid and alkali resistant, and the surface is easy to clean and disinfect.

Smart & User-Friendly

Supports remote control via Lead Fluid Cloud Pump APP (optional), featuring intelligent monitoring functions like shutdown alarms and tubing replacement reminders, making experiment management easy and worry-free.

04 Why Choose Lead Fluid

In scientific research, equipment serves as an extension of researchers’ senses. Its precision, ease of use, and durability directly impact experiment stability and results.

The application of Lead Fluid products in this groundbreaking research recognizes Lead Fluid’s years of dedication to the fluid delivery field, consistently upholding high standards, high reliability, and user-friendly design. We deeply understand that behind every piece of research data lies tremendous effort – the equipment must be trustworthy.

05 At This Moment, We Share the Honor

Witnessing the birth of disruptive technology

Experiencing the realization of green manufacturing blueprints

Lead Fluid feels profoundly honored and proud

We will continue using precision engineering to safeguard every innovative endeavor!

Together, let’s journey toward the vast universe of technological future