Water is the source of life and the root of all things. With the rapid development of economy, various pollution problems emerge one after another. Timely and effective treatment of sewage and wastewater has become an indispensable part of improving environmental quality and protecting water resources.

Recently, Lead Fluid BT300L intelligent peristaltic pump carried DT15-24 pump head into the laboratory of the School of Environmental Science and Engineering of a university in China, and assisted the sequencing batch reactor sewage treatment experiment with high-precision and stable transmission.

Lead Fluid intelligent peristaltic pump BT300L+DT15-24 with 17# silicone tube

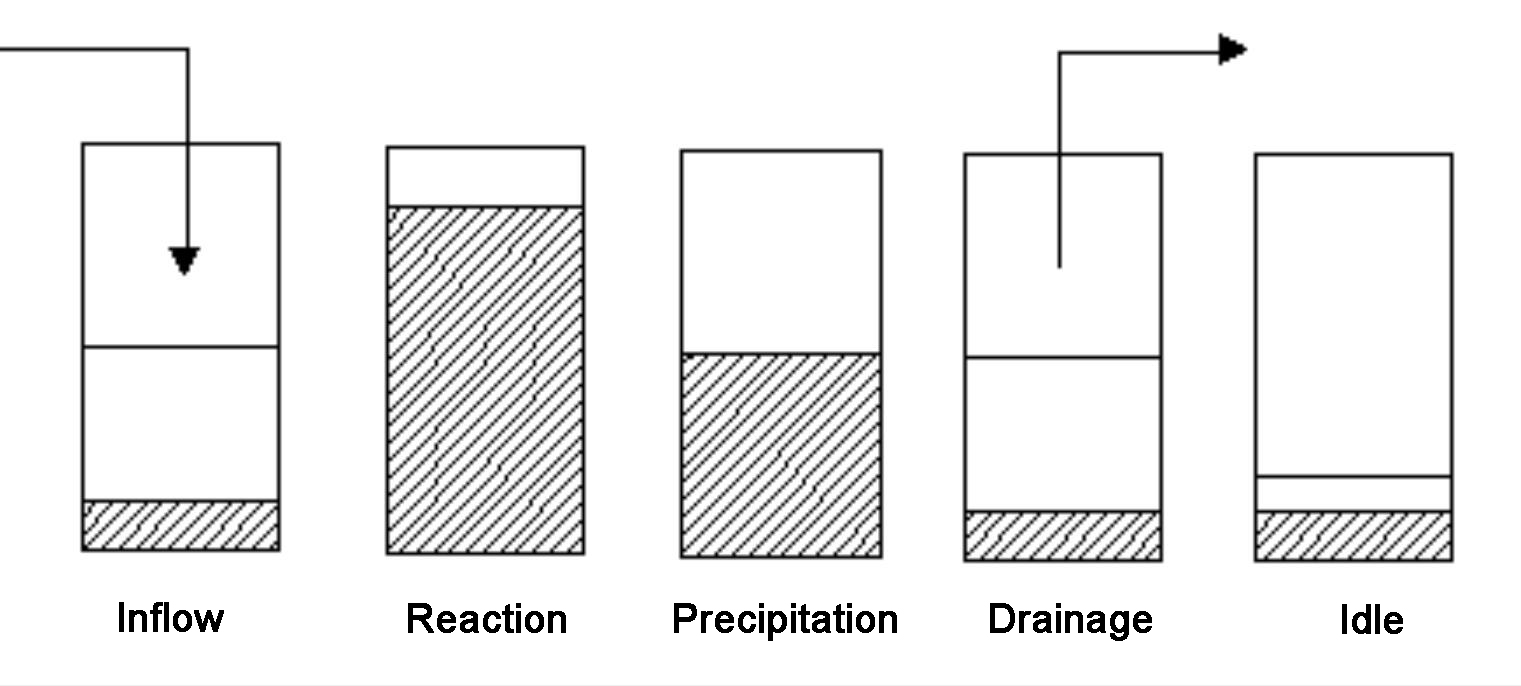

Sequencing batch reactor (SBR for short) is called sequencing batch batch activated sludge process. It is a process that carries out the operation of water inflow, reaction, sedimentation, drainage, and idle in a single reactor in a chronological order, and circulates repeatedly to achieve continuous sewage treatment.

Customer demand

Inflow and outflow have a great impact on SBR experiment. On the one hand, this cycle is a continuous cycle, with a cycle of about 4-12 hours, so the inflow and outflow determine the degree of automation of the whole experiment; on the other hand, the inflow requires a certain amount of water sample to be flowed in at the predetermined time, and the outflow is the most characteristic part of the SBR treatment process design, even related to the key part of the system operation success or failure, requiring a large outflow per unit time, small flow rate, without stirring up the sediment sludge, in other words, it must be discharged quantitatively and steadily and accurately.

Lead Fluid solution

After understanding the customer’s needs, the Lead Fluid team recommended the Lead Fluid BT300L intelligent peristaltic pump with dual-channel DT15-24 pump head to further meet the drainage requirements of SBR.

Accurate and stable transmission of timing and quantity

The instruments and equipment of scientific experiments are the extension of human senses and brain. Their accuracy, sensitivity and stability directly affect the experimental efficiency.

●High-precision transmission

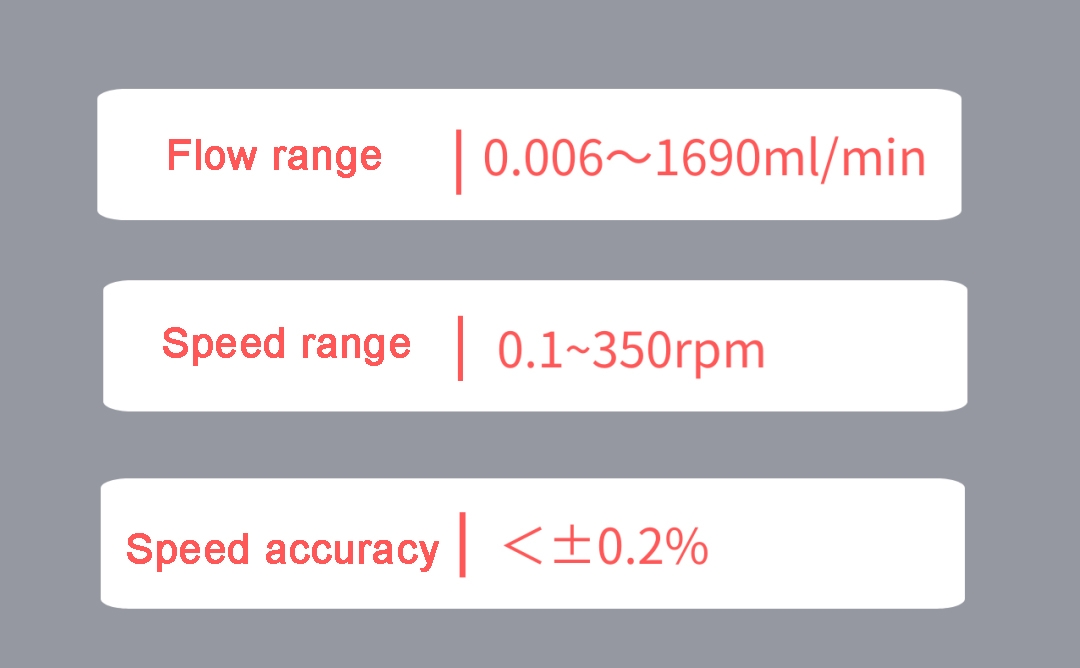

BT300L has two working modes of flow and time. It can operate only by inputting relevant parameters. Through guided flow correction and micro step algorithm, accurate measurement and quantitative transmission can be achieved within preset time. Moreover, BT300L’s programming mode supports setting 30 different quantitative parameters to facilitate complex control process.

BT300L related technical parameters

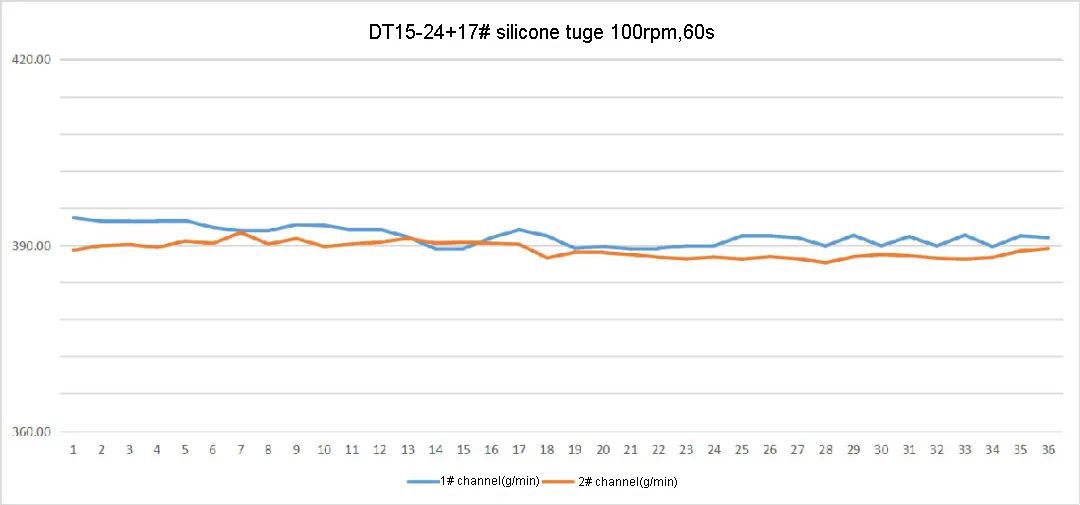

Flow change diagram of two channels of DT15-24+17 # silicone tube at 100rpm in 60 seconds

The accuracy error of BT300L rotation speed is < ± 0.2%, and the error rate of DT15-24+17 # silica gel tube in two channels within 60 seconds is 1.28% and 1.24% respectively. Error rate=absolute error/average value. The error rate is what we call precision. The lower the error rate, the higher the precision!

●Steady flow

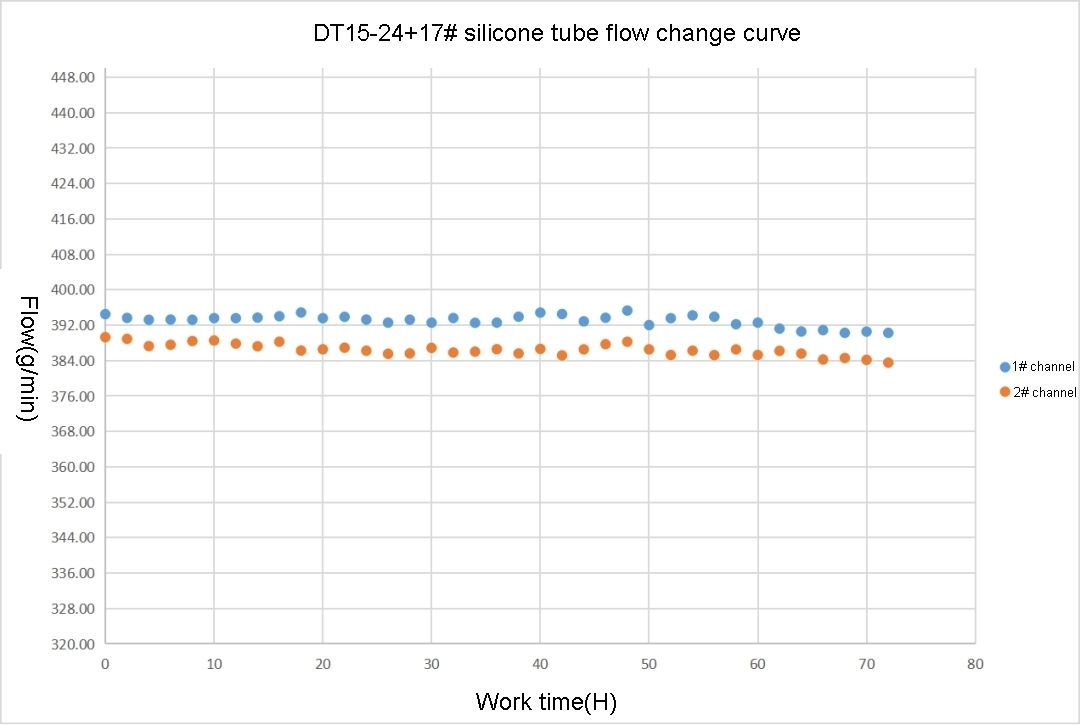

(Flow change curve of two channels of DT15-24+17 # silicone tube under 72-hour continuous operation)

Flow change rate=(flow after N hours of operation – initial flow)/initial flow, that is, the change rate of flow under continuous operation for a long time. The closer the change rate is to 0, the more stable the flow is! The flow change rate of DT15-24+17 # silica gel tube in 72 hours continuous operation is – 1.070% and – 1.477%.

Lead Fluid BT300L intelligent peristaltic pump is equipped with DT15-24 pump head and 17 # silica gel tube for high-precision and stable transmission, fully meeting the SBR process requirements.

Greater functionality

During the SBR experiment, the sewage samples are various. Some sewage particles are relatively high in content and viscosity, and are prone to blockage accidents. BT300L has monitoring functions such as shutdown alarm and pump pipe replacement reminder. Through the Lead Fluid APP software, the pump can be remotely controlled and monitored in real time. Moreover, the repeated operation can be automatically performed by setting the allocation times and the allocation interval.

DT15-24 pump head flow consistency is better

DT15-24 pump head and 17 # silicone tube

Multi-roller design can effectively reduce pulsation

Roller body bearing design, adjustable pressure tube clearance, better flow consistency

The roller is made of high-strength stainless steel, and the shell and card are made of PPS, which is high temperature resistant and chemical resistant

The plug-in card structure with independent loading and unloading makes it convenient and fast to replace and fix the pump tube

Customer feedback

The person in charge of the experiment said:

When choosing the equipment, I did a lot of homework, looked up information on the Internet, and compared the product functions. Finally, I chose and bought the products of Lead Fluid. The reliable quality and complete after-sales service are my deepest impression.