In industries such as pharmaceuticals, chemicals, and food, filling is an indispensable “key link” in the production process. Accuracy, efficiency, and compliance have always been the core requirements for equipment within these industries. However, traditional equipment, due to cumbersome operations, complex debugging, and low efficiency, has become an “invisible obstacle” in production lines.

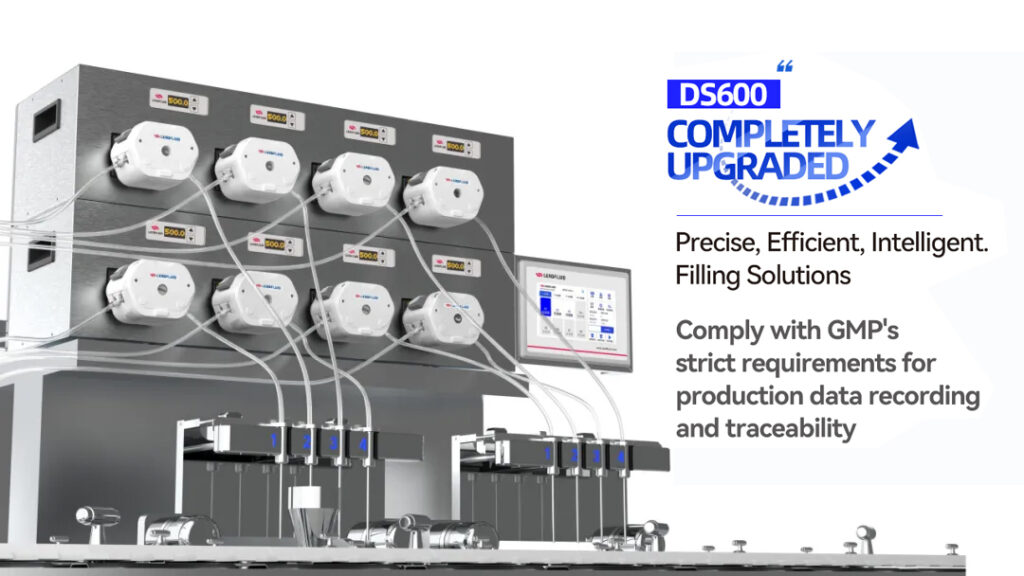

The Lead Fluid DS600 filling system has been fully upgraded! Unlock higher productivity with an accurate, efficient, and intelligent filling solution!

01 Why Choose the DS600

The DS600 strictly adheres to GMP standards, meets 3Q certification, and through intelligent management and flexible design, helps enterprises achieve more efficient and stable production operations.

02 Core Highlights Preview

Complies with industry standards, reduces risk

• Adheres to GMP Standards:Stainless steel material, streamlined design with no dead angles, effectively prevents cross-contamination

• Meets 3Q Certification:Supports verification documents, automatically records operation logs, ensures compliance

Stable and Efficient, Accurate Filling

• Online Fine Adjustment:Convenient and quick adjustment of filling errors, ensuring precise filling

• Supports Connection to Weighing Platform:Automatic calibration, eliminates complex debugging, swiftly enters production

•Flexible Channel Settings:Independent control for single channel, or one-click copy to other channels, easily meets multi-batch production requirements

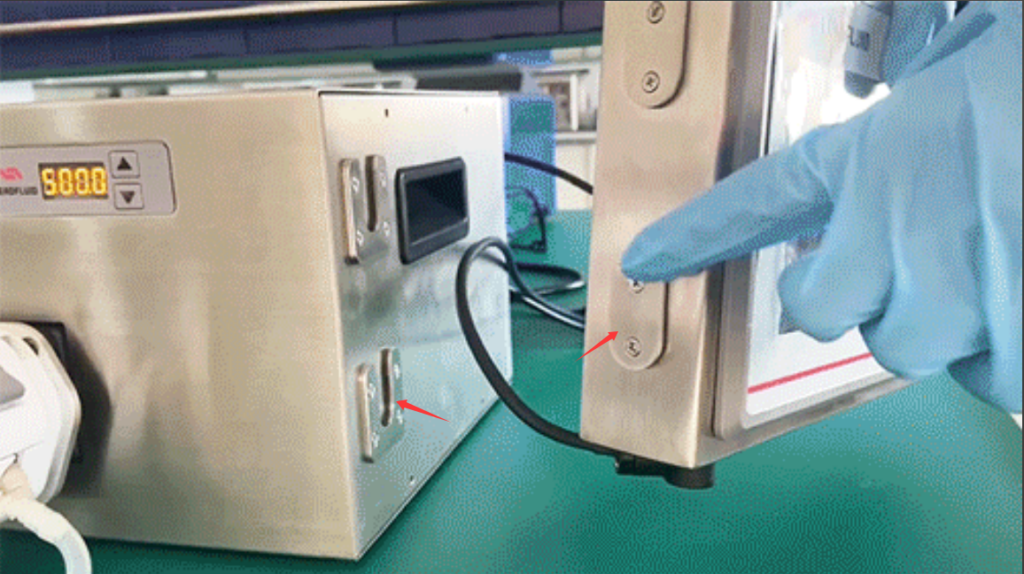

Modular Design, Easy Maintenance

• Quick Replacement:Easy disassembly and assembly of channel modules, reducing downtime

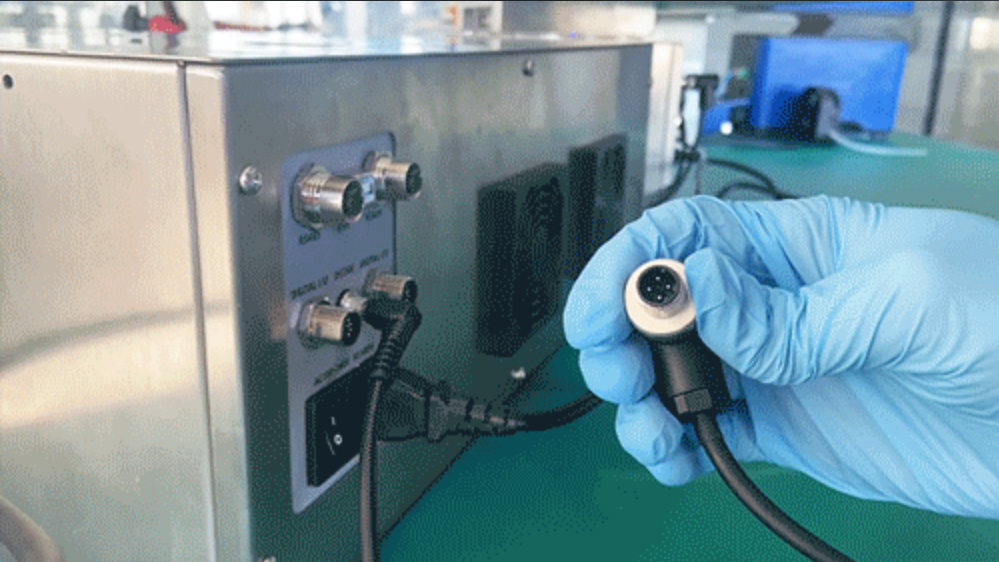

• Aerospace Connector: Stable connection, standardized external control line, ensures long-term stable operation of the equipment

Flexible Expansion, Supports Future Capacity Upgrades

• 32-channel Compatibility: Suitable for complex processes, supports capacity expansion

• Split-controlDesign: Can be hung or placed flat, flexible layout, easily adapts to different production spaces

Intelligent Operation, Easy Management

• Formula Management: Supports USB import/export, custom naming (including Chinese), enhances production efficiency

• Video Guide:Intuitive operation guide, helps new users quickly get started

• Filling Times and Interval Settings:Flexible configuration, meets semi-automatic production requirements

✨ Simple UI, User-Friendly

New Interface: Clear and intuitive, reduces misoperation, enhances user experience

03 Applicable Industries

Filling production in pharmaceutical, chemical, and food industries.

Intelligence leads the future, efficiency creates value!

Lead Fluid DS600, empowering production, accelerating efficiency!

Follow Lead Fluid’s official account to learn more about product details and successful cases, and start your new era of production!