Tangential flow filtration refers to the filtration form in which the liquid flow direction is perpendicular to the filtration direction, which can quickly and efficiently separate and purify biological molecules. It can be used for concentration and desalination of sample solutions as low as 10 ml and as high as thousands of liters.It can also be used for the separation of biomolecules of different sizes, collection of cell suspensions, and clarification of fermentation broth and cell lysate. It is a filtration method commonly used in biopharmaceutics.Peristaltic pump plays an important role in tangential flow filtration. Let’s explore it together.

01

Tangential flow filtration VS traditional filtration

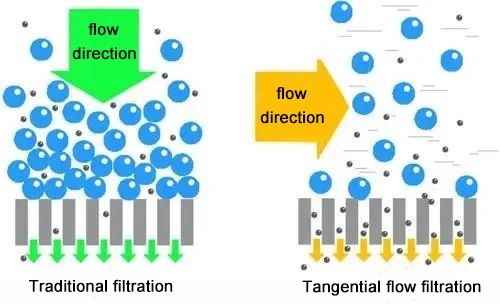

The traditional filtration method is the filtration form adopted by most microporous filtration (MF, microfiltration) and bactericidal filtration. The flow direction of the liquid is consistent with the filtration direction. With the progress of filtration, the thickness of the filter cake layer or gel layer formed on the surface of the filter membrane gradually increases and the flow rate gradually decreases.

When the filtering medium is ultrafiltration membrane or microfiltration membrane with small pore diameter, the solid content in the feed liquid is very high, and the flow rate will be rapidly reduced by adopting the traditional filtering method, so the traditional filtering can only deal with small volume of feed liquid.

Tangential flow filtration is one of the pressure filtration/membrane filtration technologies. The flow direction of the filtrate is parallel to and perpendicular to the filtering direction of the filter membrane. A small part of small molecules pass through the filter membrane, and macromolecules are taken away from the surface of the membrane. With the increase of time, the number of particles accumulated on the membrane surface is limited, which does not affect the filtering speed and effect. Compared with the traditional filtering method, it is more suitable for large-scale filtration of material and liquid.

02

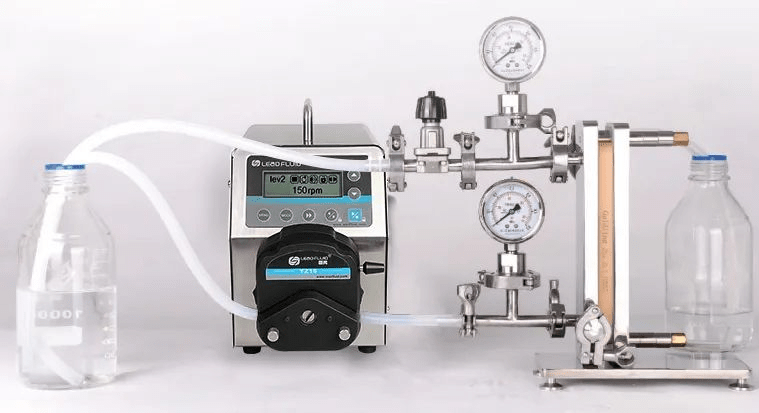

Peristaltic pump assisted tangential flow filtration

In the application of tangential flow filtration, the delivery pump is required to provide pressure to drive the filtrate through the filter and provide transmembrane pressure, so that the excess water molecules and other small molecules (colorless and transparent) in the solution can pass through the ultrafiltration membrane and be collected in a fixed container. It is required that the delivery pump must have the characteristics of high precision, stable delivery and low shear force.

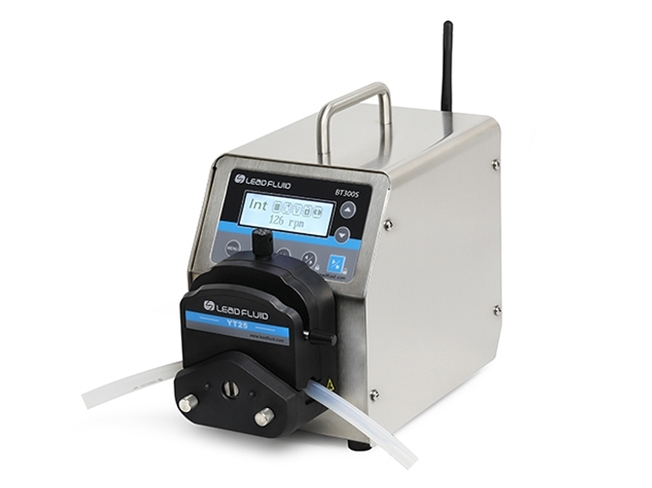

The Lead Fluid BT300S peristaltic pump can perfectly match this requirement. It is equipped with an imported core processor, driven by a high-quality stepping servo motor, with a rotation control accuracy of ± 0.2% and a precise speed, which can achieve high-precision flow transmission.

The Lead Fluid BT300S peristaltic pump has the function of slow speed stop, which makes the transport fluid more stable and improves the stability during filtration. It is more convenient to control on the cloud. The pump can be remotely controlled and the running status can be monitored in real time through the RAEVE APP software.

The Lead Fluid BT300S peristaltic pump has the characteristics of low shear force and is an ideal tool for conveying shear sensitivity. It can transport liquid materials and macromolecular materials containing solid particles without changing the state of materials.

In addition, the Lead Fluid BT300S peristaltic pump has the characteristics of low maintenance cost. The pump body does not contact the delivered fluid, and the only contact is the peristaltic pump pipe. It only takes one minute to replace the peristaltic pump tube.

Lead Fluid BT300S peristaltic pump has higher accuracy, stable flow and convenient maintenance, which can effectively improve the efficiency of fluid transmission in tangential flow filtration.

Welcome to connect Lead Fluid company for more details.