1.Syringe Pump Definition

The syringe pump is composed of a precision motor, a drive unit, a screw rod, a push block and a fixed bracket, etc., which can move back and forth.

The push block is connected with the push rod of the syringe to push or pull the piston, so as to realize high-precision, smooth and pulsation-free liquid transmission.

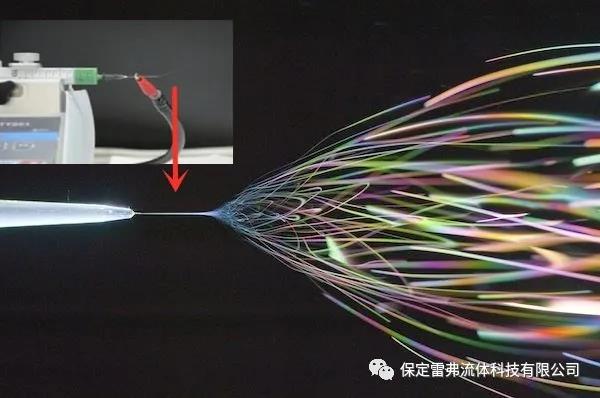

2.Principle of High Voltage Electrospinning

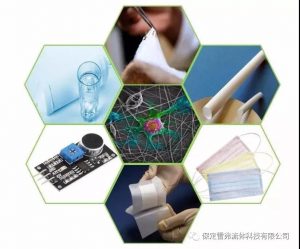

Electrospinning is a special form of electrostatic atomization of polymer fluids. A high-voltage electrostatic field is applied between the injection device (syringe pump) and the receiving device. The injected polymer forms a micro jet, and finally a non-woven fabric is formed on the receiving device. The process of state of nanofibers. Electrospinning can prepare fibers with diameters of tens to hundreds of nanometers. The products have high porosity and large specific surface area, diversified components, uniform diameter distribution, and are very useful in the fields of biomedicine, environmental engineering and textiles. High application value.

3. Solution

Lead Fluid high-precision laboratory syringe pump can be equipped with a syringe with a capacity of 10 uL to 60 mL. It has 1, 2, 4, and 10 channels to choose from, achieving a single channel flow range of 0.184nl/min—83ml/min.

Recommended reference model:

TYD01-01(single channel syringe pump)

TYD01-02(dual channels syringe pump)

TYD03-01(high precision single channel syringe pump)

TYD02-10(ten channels syringe pump)

4. Main Feature

♥ Integrated desktop design, 4.3-inch high-definition color LCD touch screen display and operation, convenient operation parameter setting, operation information and status at a glance.

♥ The syringe capacity is 10 uL to 60 mL.

♥ Using excellent control system and precise mechanical structure, stroke control accuracy error <±0.35%, multiple working modes are available.

♥ Advanced micro-step control technology to ensure high stability and uniformity of operation at any flow rate (including resonance flow rate).

♥ The fixing method of the drive screw adopts high-strength aviation bearings, and the force transmission structure adopts a unique mechanical design to ensure the stability of the injection pump under high-strength operation.

♥ Strong anti-electromagnetic interference performance, in actual use, it can operate continuously and stably under a high-voltage electrostatic field of up to 40KV without an external isolation transformer.

♥ Support RS485 communication, compatible with MODBUS protocol, and can form an automated control system with computers, PLCs, and single-chip computers.

5.Schematic Diagram

In recent years, with the continuous in-depth research on electrospinning theory, electrospinning technology has received attention in many research fields, especially in the fields of biomedicine, energy storage, environmental cleaning and catalysis. Electrospinning Because of its many advantages, technology has gradually become an important technology for preparing one-dimensional nanomaterials.

As a manufacturer with more than 20 years of research and development, production technology and experience, Lead Fluid has always had a high reputation in the industry, and our series of syringe pump equipment has also been in the leading position in the industry. Nowadays, in any microfluidic application field that requires precise injection, Lead Fluid has been recognized as a leading brand, able to provide customers with all the technical requirements of various syringe pumps, and provide special customized syringe pumps to meet all customer needs.