♦ Lead Fluid TY15 peristaltic pump continuously working flow range 0.004~140ml/min,intermittent working flow range 0.004~420ml/min.

♦ Elastic roller body, with flexible pressure pipe structure pump head,provides excellent pump tube life.

♦ Tube connector with built-in tube,ingenious fixed structure,easy to change, stable and reliable.

♦ Pump head uses a variety of high-performance materials,high mechanical strength, excellent corrosion resistance and aging resistance.

♦ Suitable for AC motor and stepper motor, especially suitable for long-term use on online monitoring instruments such as COD, CEMS.

Pump Head Material

| Shell | IXEF |

| Roller | PVDF |

| Roller shaft | SS304 |

| Upper block | PVDF |

| Tube connector | PP/PVDF |

Flow Rate Parameter

Tube material:Silicone, Pharmed, Viton, Norprene Wall thickness1.6mm

| ID(mm) | 2.4 | 3.2 | 4.8 |

| 19# | 16# | 25# | |

| Milliliter/Revolution | 0.4 | 0.74 | 1.4 |

| mL/min (Continuously working max100rpm) | 40 | 74 | 140 |

| mL/min(Intermittent working max 300rpm) | 120 | 222 | 420 |

Above parameters are obtained by using silicone tube to transfer pure water under normal temperature and pressure, in actually using it is effected by specific factors such as pressure, medium. Above for reference only.

Motor Specification

| 57 Stepper motor | Step angle 1.8° \ phase 2 \phase voltage 3.9V \ phase current 3A \ phase resistance 1.3Ω±20% \ phase inductor 5.0mH±20% |

| Insulation grade : 1≥100MΩ | |

| Wiring definition: red line-A, green line-C , yellow line-B , blue line-D |

| 50 AC synchronous motor | Speed: 5rpm , 8rpm ,10rpm ,30rpm , 65rpm ,80rpm ,170rpm |

| Power supply : AC220V / 50Hz | |

| Power: 1W | |

| Direction: Reversible direction |

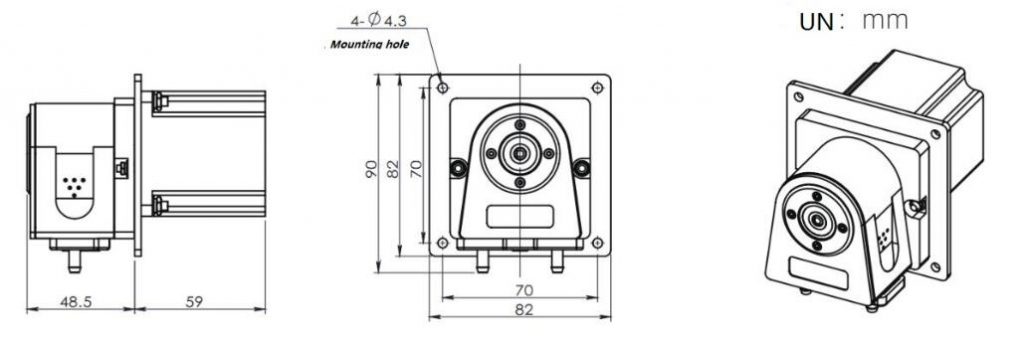

Dimension(57 Stepper Motor)

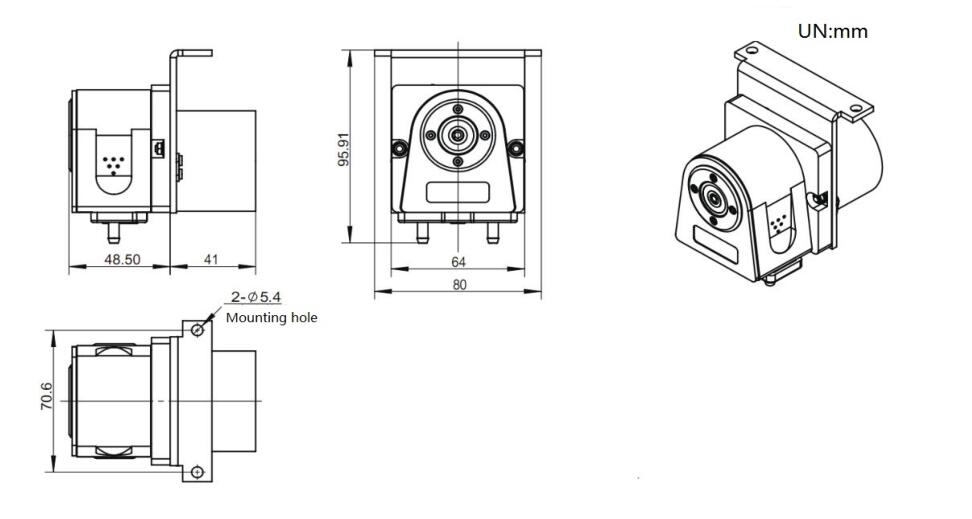

Dimension(50 AC Motor)

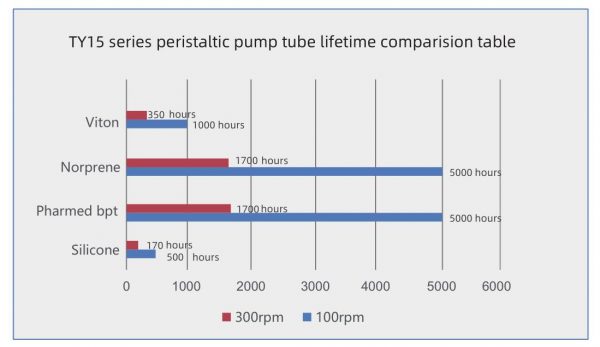

Tube Lifetime Comparision Table

Important tips:

A. For longer tube lifetime, choose thicker wall tube and low speed.

B. For larger flow,choose larger ID tube and in high speed.

C. For higher precision, choose smaller ID tube and medium to high speed.

D. For higher suction and back pressure,choose thinner ID and thicker wall tube and low speed.

Statement:The final explanation right of above information belongs to Lead Fluid.